Workpiece machining flexible production line and machining method implemented through same

A flexible production line and processing method technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of easy deformation, difficult to ensure accuracy, high requirements for geometric tolerance accuracy, and achieve noise and vibration reduction. Stable quality, guarantee the effect of size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

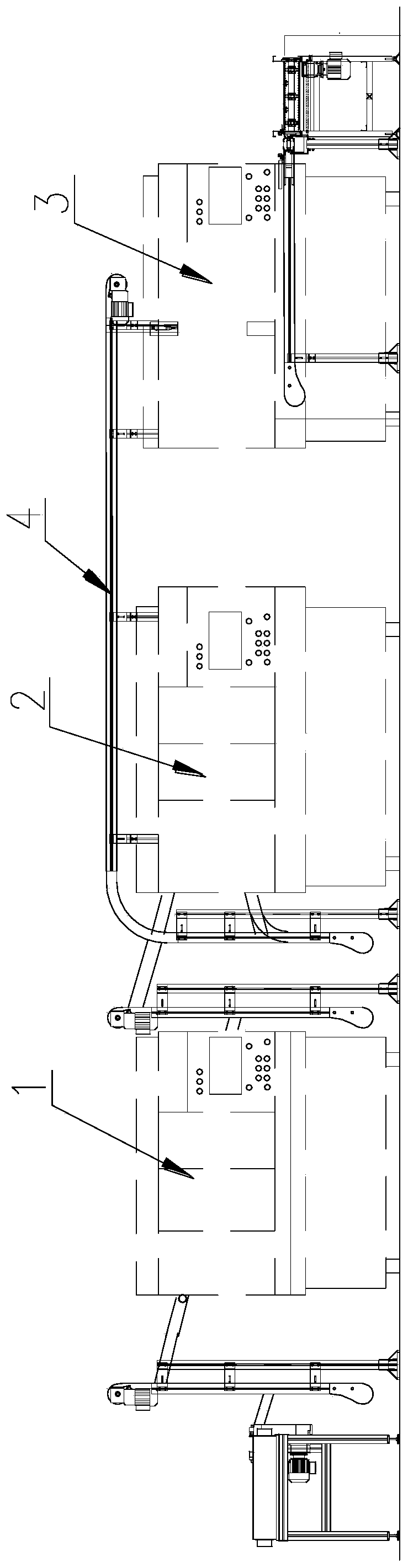

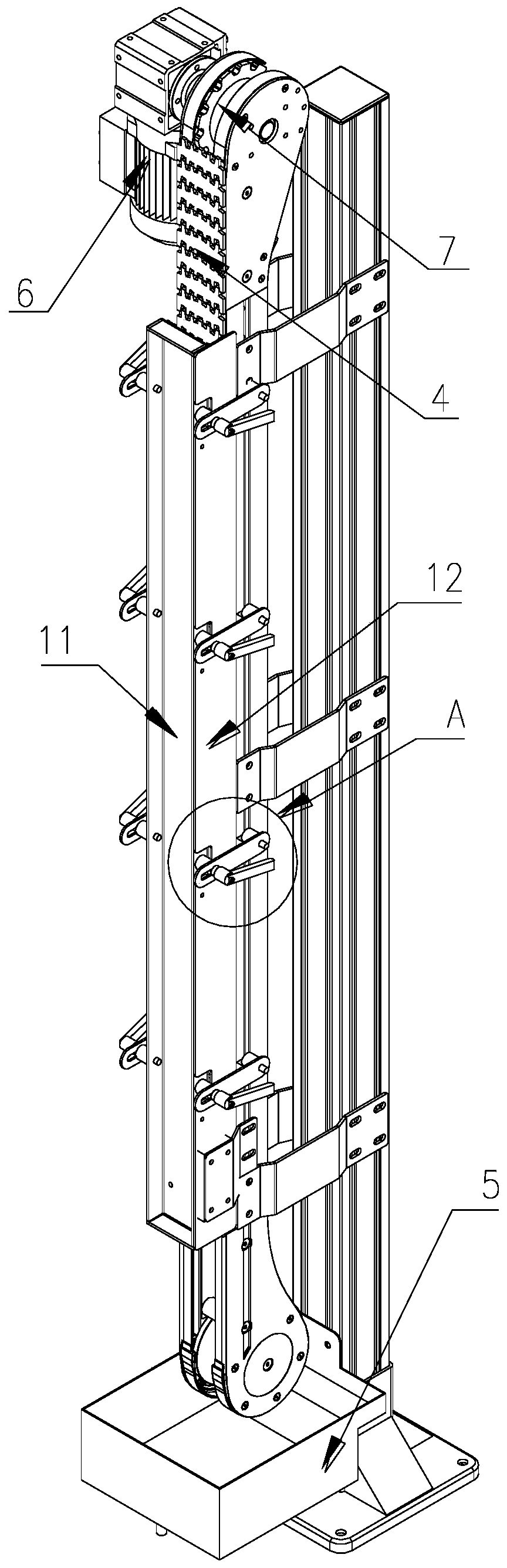

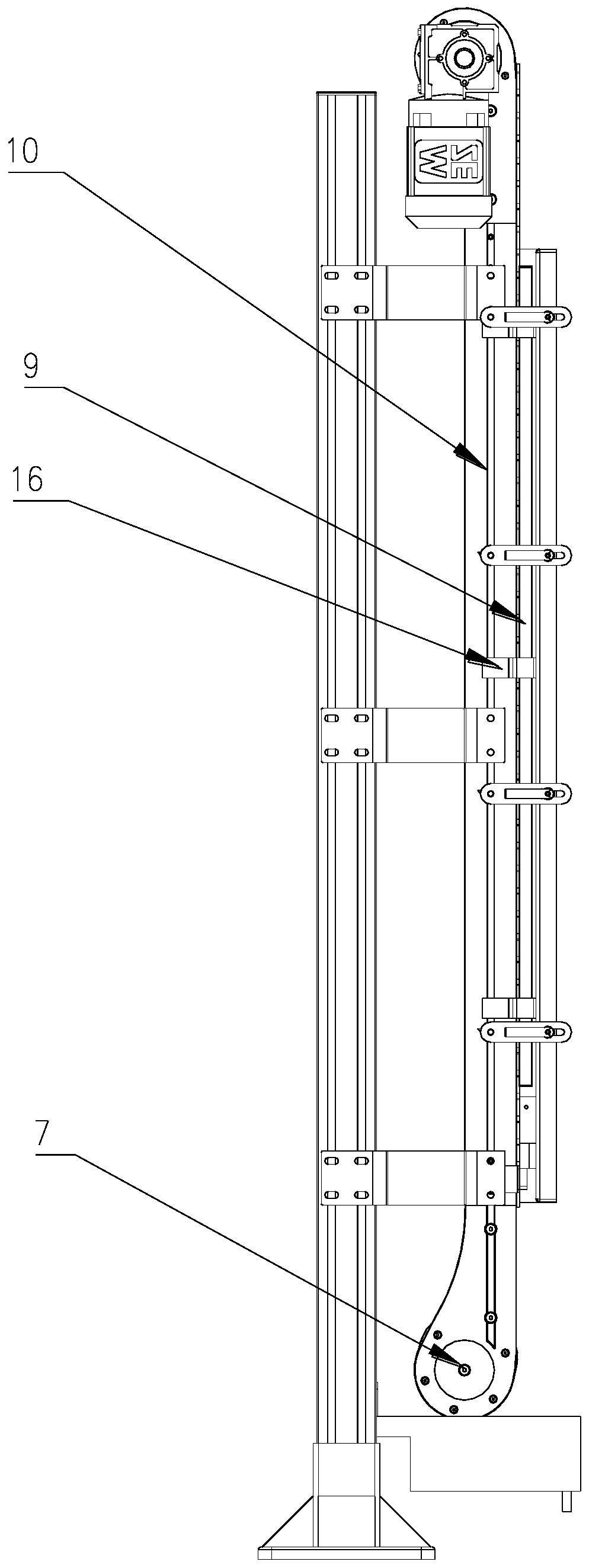

[0037] Embodiment one: if figure 1 As shown, the flexible production line for universal joint cages according to the present invention includes each production unit for processing machine parts and a transmission system connected between each production unit, and the production unit includes a rough machining unit 1, a finishing unit Unit 2 and station unit 3, the rough machining unit 1 includes a rough grinding unit, and the rough grinding unit includes a double-turret CNC lathe arranged at the upstream of the transmission system. When grinding the upper and lower planes of the cage window, it is necessary to Guarantee the width of the 6 windows and the size of the centerline of the window to the reference plane B, locate the reference plane B, directly measure the width of the window and the height of the bottom surface of the window and the reference plane, so as to indirectly ensure the alignment of the centerline of the window to the reference plane B Dimensions. Therefor...

Embodiment 2

[0041]A processing method for processing a universal joint cage, comprising the following steps

[0042] The first step is to form the inner and outer spherical surfaces of the circular blank, and process the blank through the rough processing unit to form the inner and outer spherical surfaces;

[0043] The second step is positioning with the inner spherical surface and the reference plane B, using an automatic indexing device to punch 6 windows, and the reference plane B (the reference plane B can be reasonably determined by those skilled in the art as required);

[0044] The third step is carburizing and quenching, tempering and tempering to 58-62HRC, and quenching the stamped materials;

[0045] The fourth step is flat grinding rough and fine grinding datum plane B;

[0046] The fifth step is to position with reference plane B, grind 6 windows, and perform finishing machining;

[0047] The sixth step is to position the outer spherical surface and the reference plane B, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com