Multilayer plywood fully-automatic production line

A fully automatic, plywood technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of inability to adapt to industry production and market demand, increase in labor costs, time-consuming and labor-intensive efficiency, etc., to save manpower and improve work efficiency Efficiency, the effect of improving the carrying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] To facilitate the understanding of those skilled in the art, the following is attached Figure 1-5 , The technical scheme of the present invention is further explained in detail.

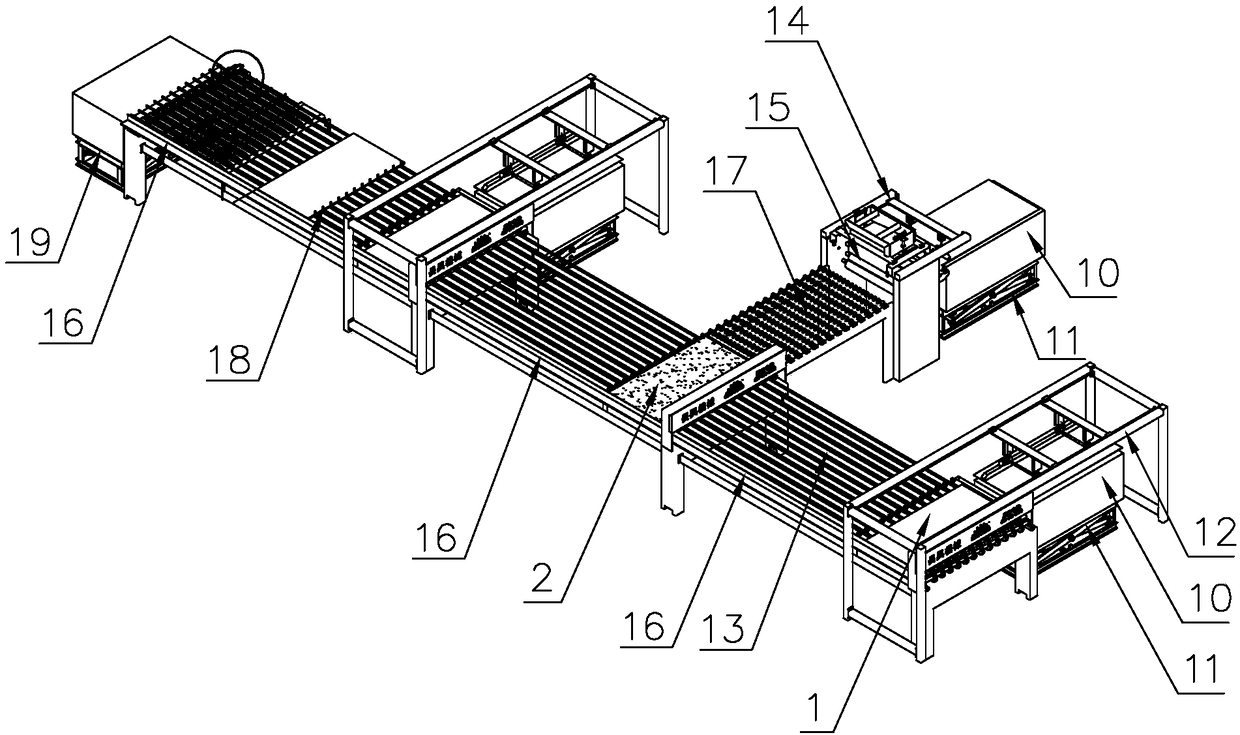

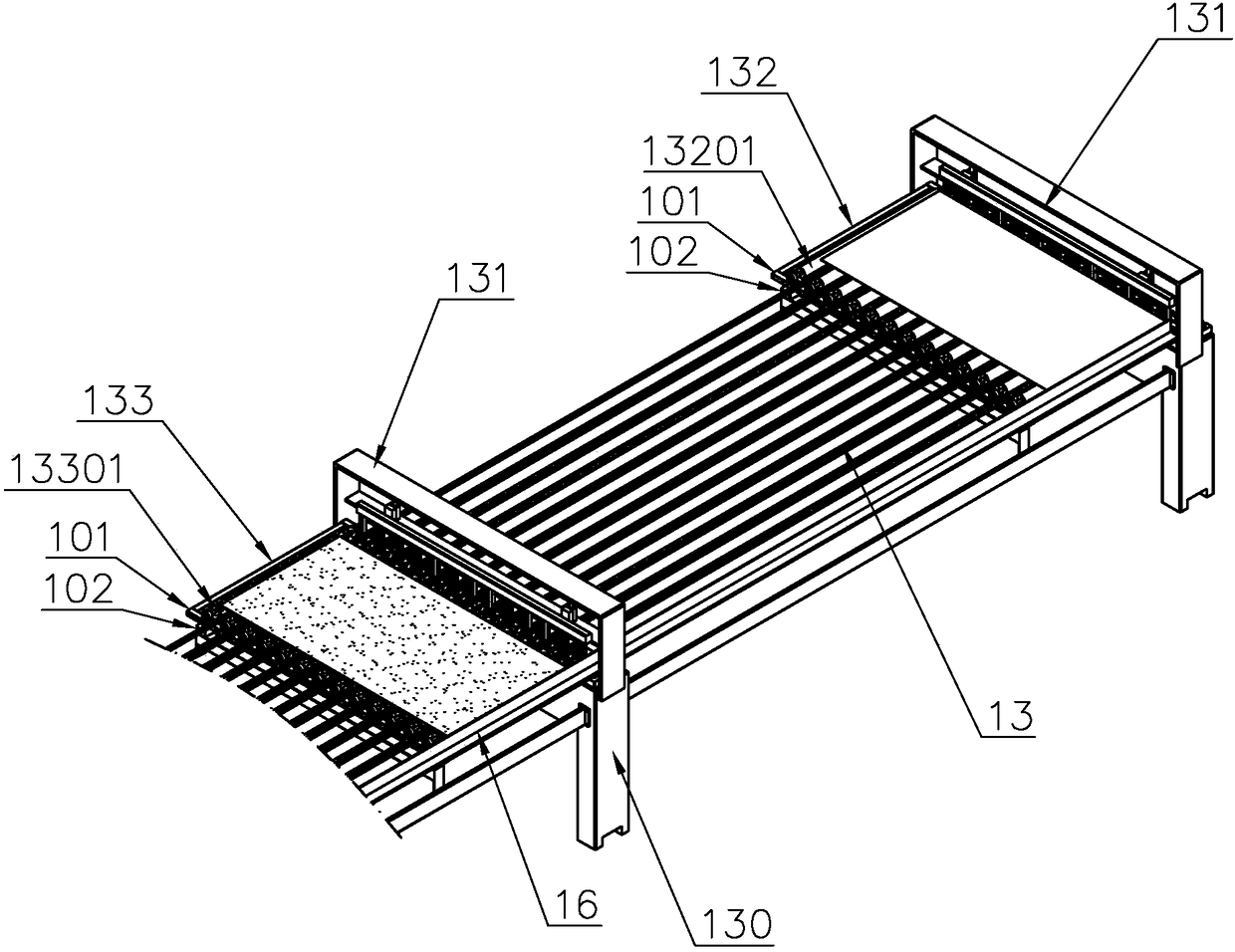

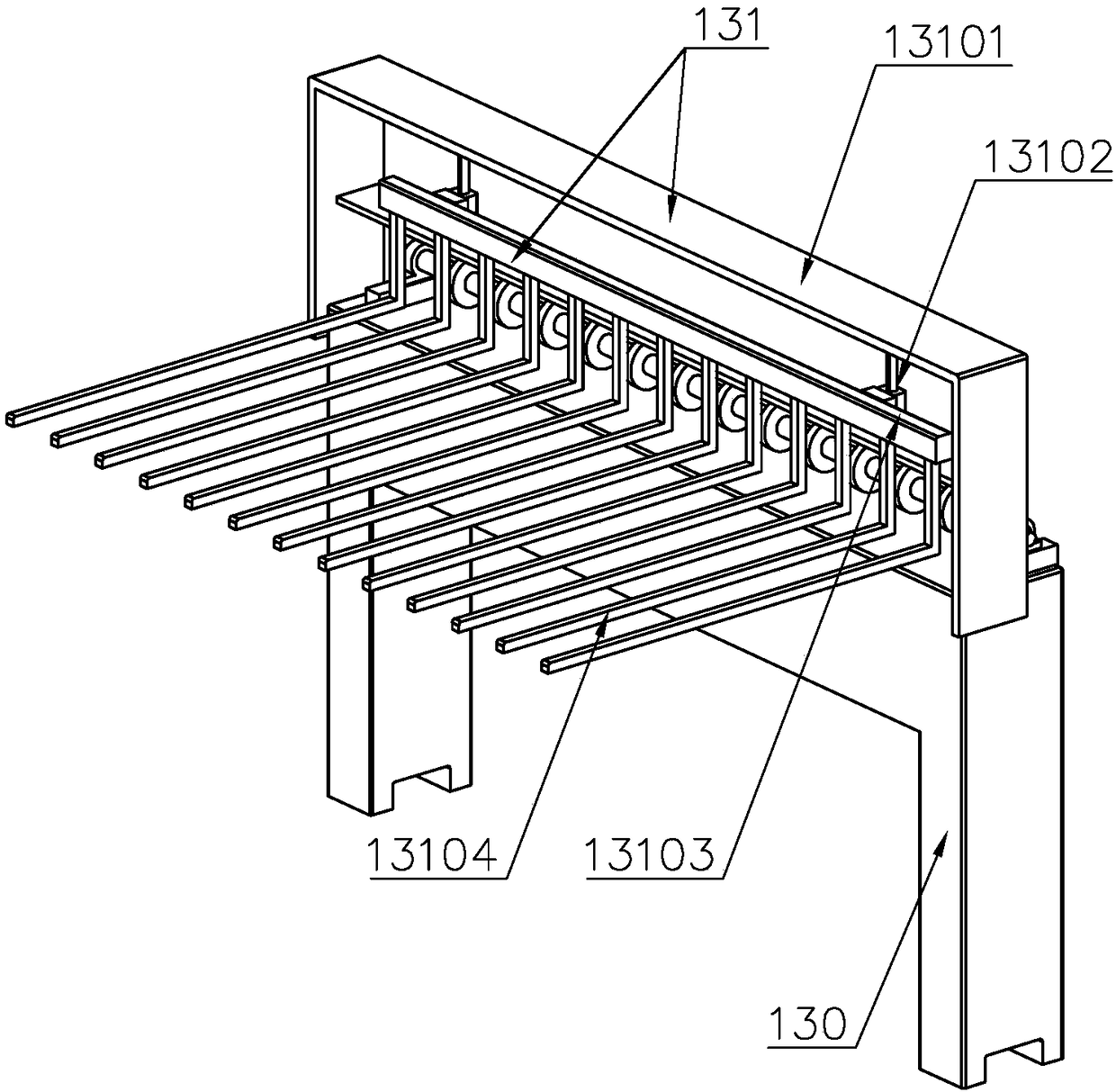

[0043] A multi-layer plywood automatic production line, including automatic lifting table 11, horizontal feeder 12, veneer conveyor line 13, vertical feeder 14, automatic glue spreader 15, top ruler 16, and plywood conveyor line 17 , Transverse moving ruler 18, automatic palletizer 19, the veneer conveyor line 13 is provided with a transverse moving ruler 18 on the conveyor chain, and the chain rotates to drive the lateral movement ruler 18 to position the veneer laterally; The upper part of the frame 130 in the line 13 is provided with a top end ruler 16. The lateral movement ruler 18 and the top end ruler 16 on the veneer conveyor line realize a positioning right angle for the veneer assembly, so as to better align the plywood Stacking and grouping blanks; the veneer conveyor line frame 130 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com