Automatic grab mechanism, automatic grab method and polishing machine provided with automatic grab mechanism

A grasping mechanism and automatic technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of low degree of automation, low precision and low efficiency, and achieve the effect of high degree of automation, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

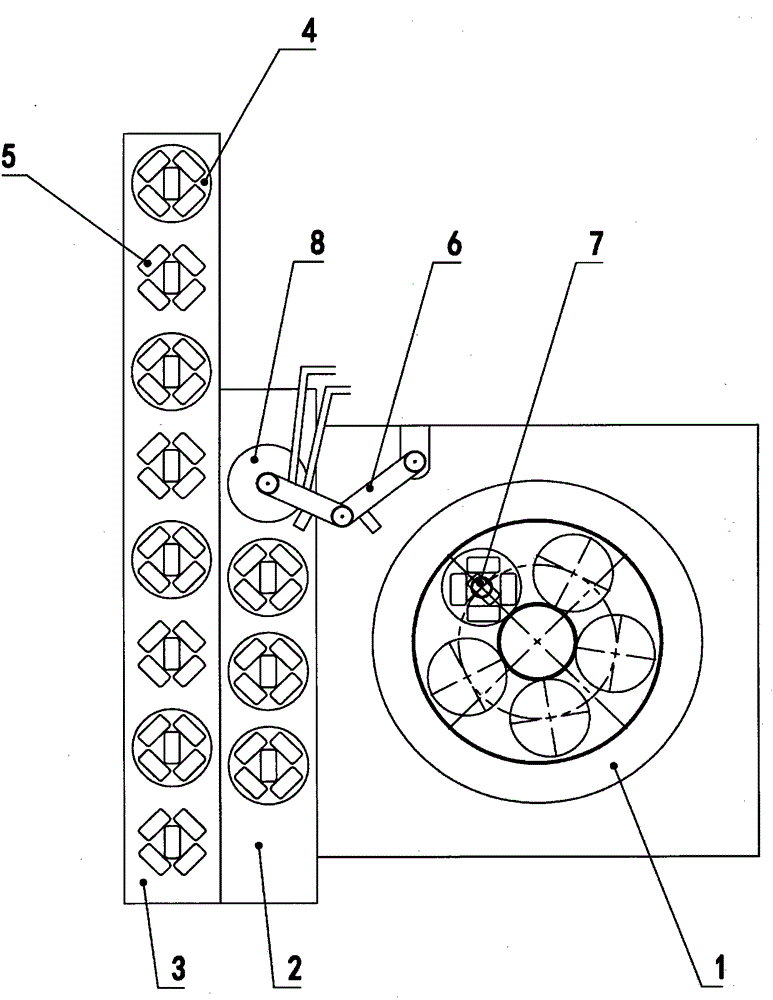

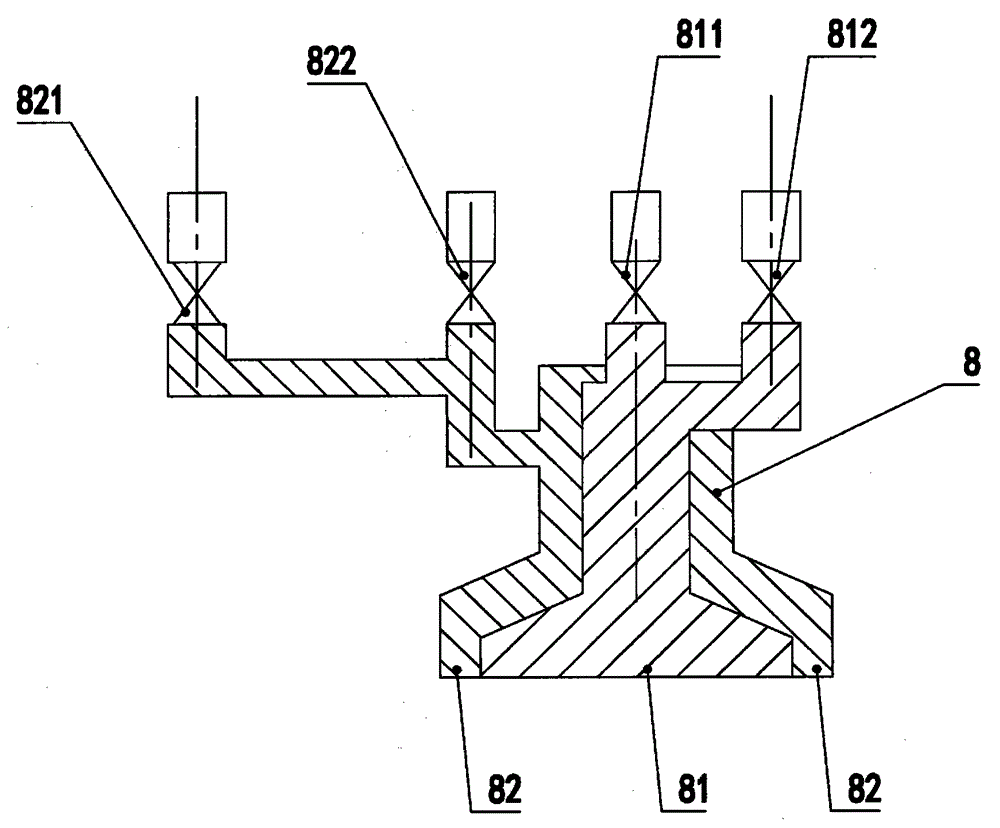

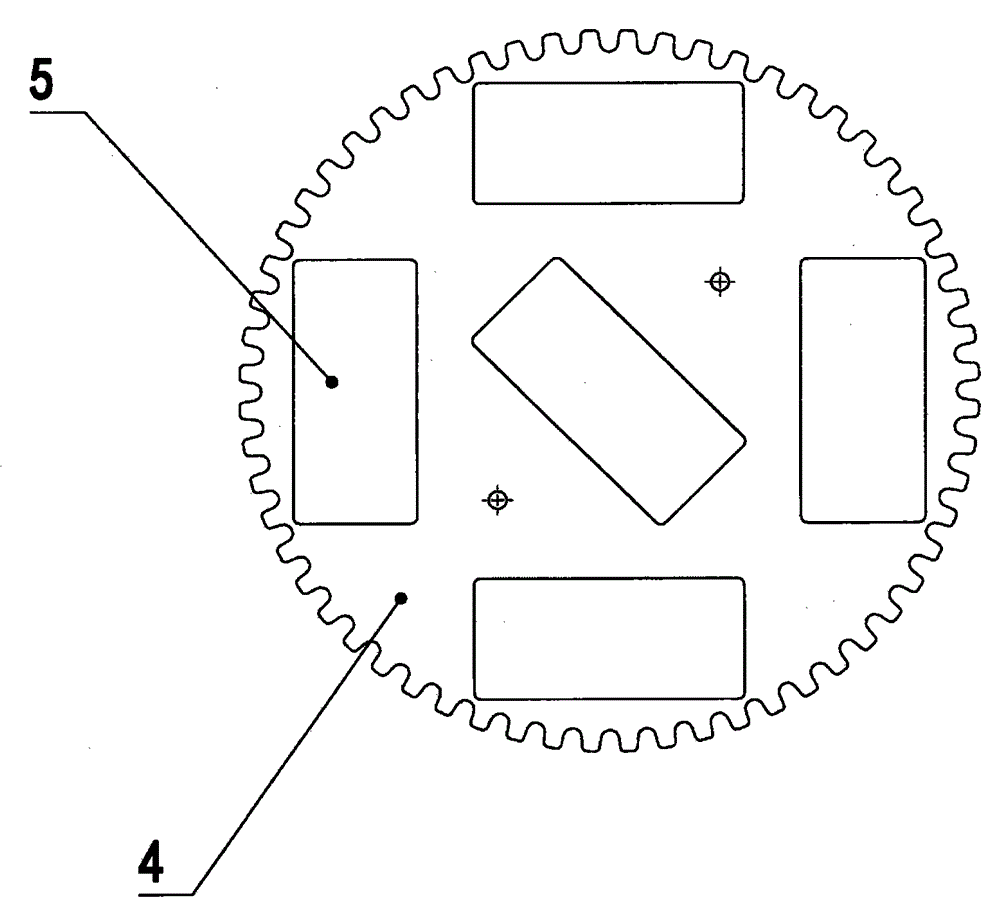

[0031] Figure 1 to Figure 4 The reference numerals in the drawings are: grinding disc 1; working belt 2; feeding belt 3; planetary fixture 4; glass 5; manipulator 6; visual detector 7; air distributor 8; main chamber 81; Main chamber negative pressure valve 812; auxiliary chamber 82; auxiliary chamber positive pressure valve 821; auxiliary chamber negative pressure valve 822; capsule sucker 9.

[0032] Such as Figure 1 to Figure 4 As shown, an automatic grabbing mechanism includes a manipulator 6 and an extraction tray connected to the manipulator 6, the extraction tray is an airflow distributor 8, and the airflow distributor 8 is provided with a main cavity 81 and a secondary cavity 82, The main chamber 81 is connected with a main chamber positive pressure valve 811 and a main chamber negative pressure valve 712 through pipelines, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com