Method for machining perpendicularity gauge

A processing method and technology of measuring gauges, applied in the field of mechanical processing, can solve the problems of affecting the measurement effect, long grinding stroke, unusable gauges, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

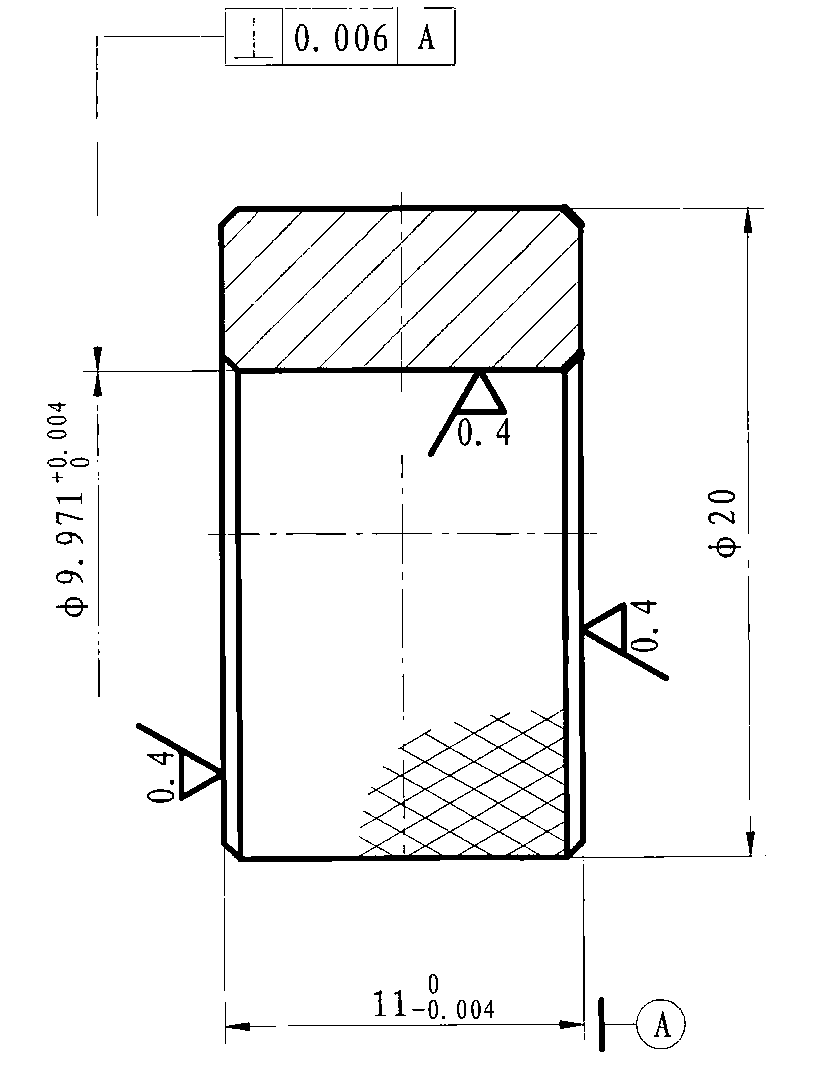

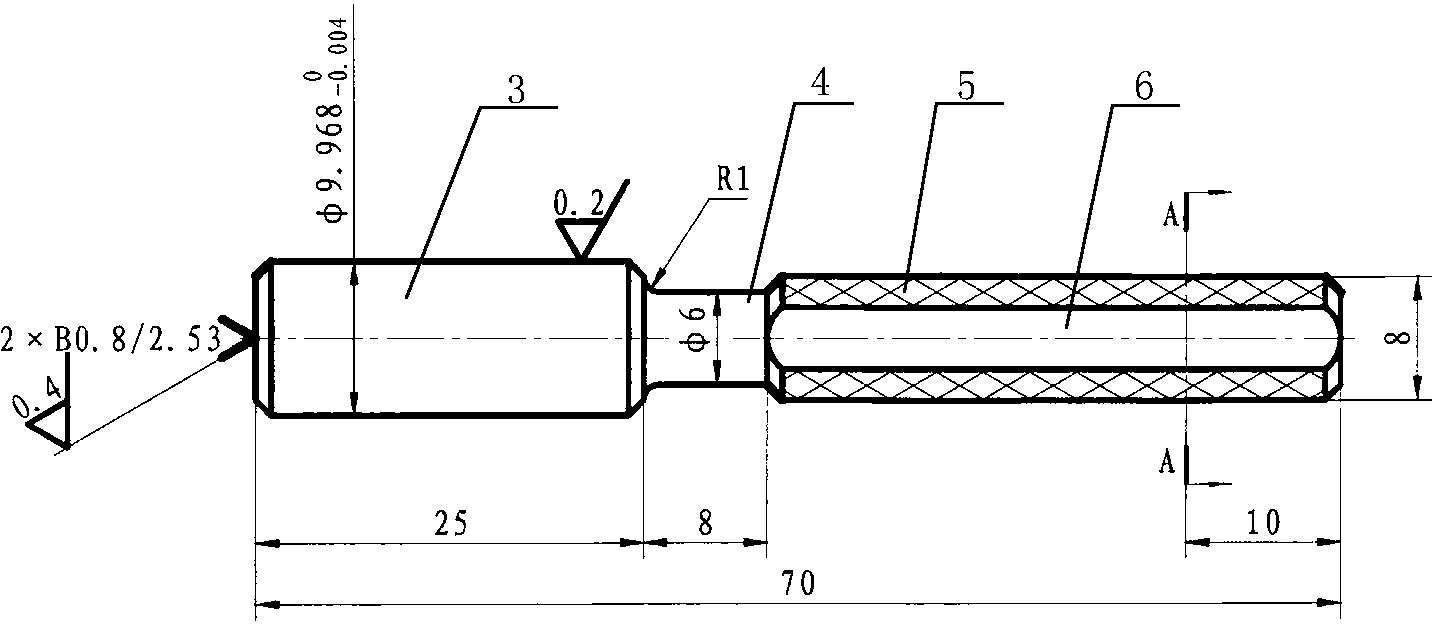

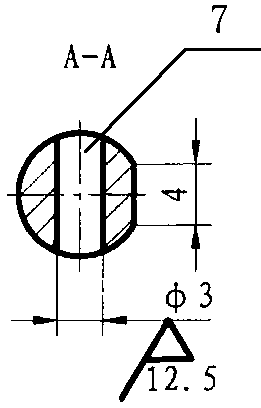

[0025] Such as Figure 1~4 As shown, a vertical gauge includes a movable gauge 1 and a measuring gauge 2, the movable gauge 1 is a torus, the outer circumference of the movable gauge 1 is rolled with texture, and the measuring gauge 2 includes a measuring part 3, an empty knife part 4 and Handle part 5, the outer diameter of measuring part 3 matches the inner diameter of movable gauge 1 and the inner diameter of the hole to be measured. Some are also provided with a marking surface 6 and a hanging hole 7 . The material of the vertical gauge is CrWMn, which is the most commonly used high-carbon alloy tool steel for making special measuring tools.

[0026] Such as Figure 5~6 As shown, the groove distance between the two lugs to be measured is 11mmH12, the two holes of the lugs are φ10mmH8, and the verticality required for measurement is 0.05. Therefore, the dimensions of the designed activity gauge 1 and measuring gauge 2 are as follows Figure 1~3 shown.

[0027] The proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com