Glue spreading equipment and gluing process of decorative plate

A technology of gluing and equipment, which is applied in the field of plate processing, can solve the problems of not being able to stick tiles firmly, cannot control the thickness of the glue, and will not be too firm, and achieve the effect of suitable glue coating thickness, good gluing effect, and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

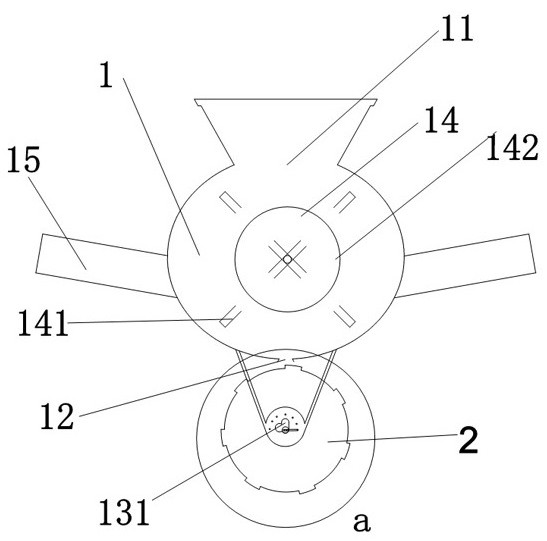

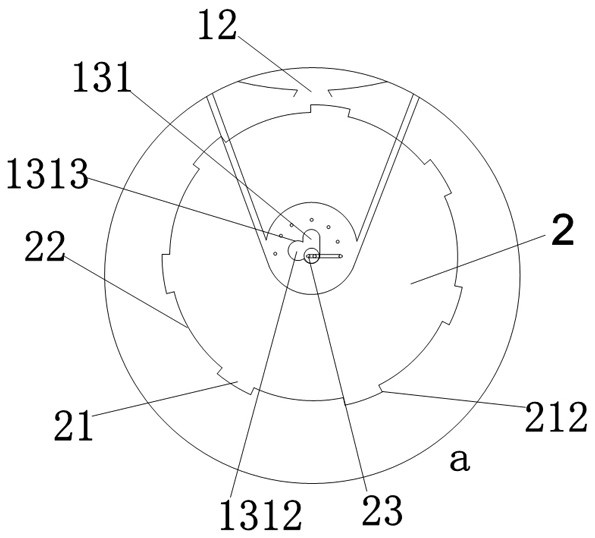

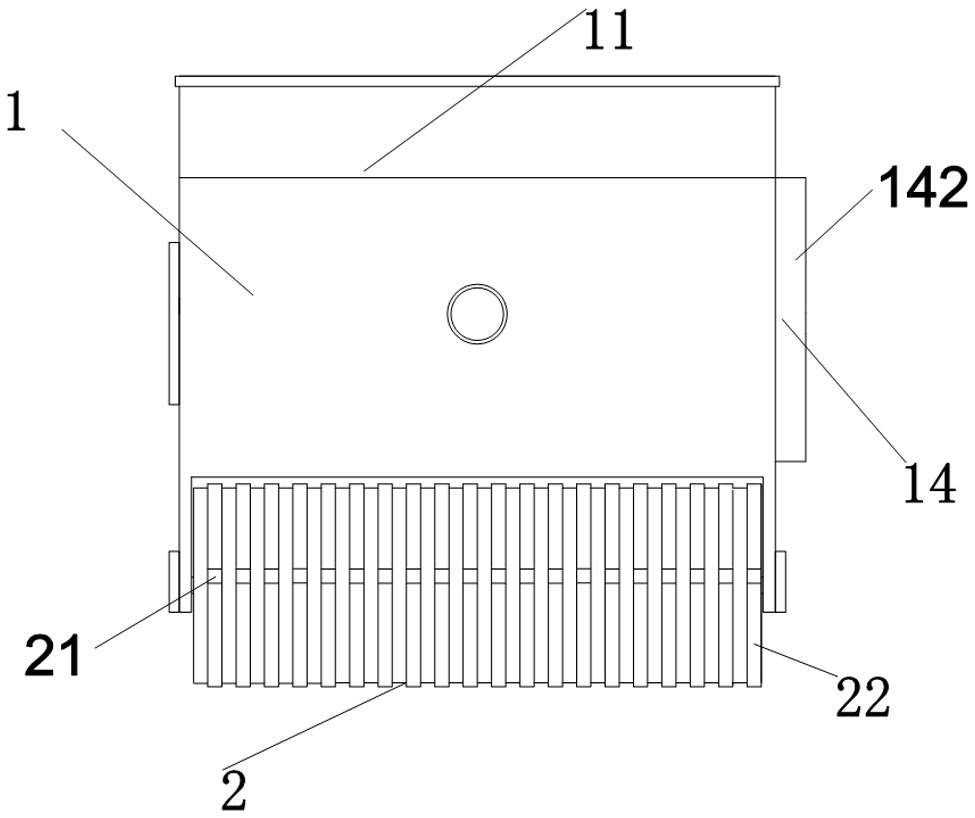

[0036] A kind of gluing equipment, comprising a rubber mixing cylinder 1 for mixing and containing glue and a glue roller 2 arranged under the rubber mixing cylinder 1 for receiving glue, and the rubber mixing cylinder 1 has at least one setting In the feed port 11 on the upper part and the discharge port 12 provided on the lower part, the rubber mixing cylinder 1 is provided with an adjustment notch 131 fixed thereto at least including two adjustment positions, the adjustment notch 131 is sleeved on the rotating shaft of the gluing roller 2, so that the rubber mixing cylinder 1 can adjust the positional relationship with respect to the gluing roller 2 at least in the up and down direction; the circumferential direction of the gluing roller 2 is provided with multiple Radial protrusions 21, arc-shaped cylindrical surfaces 22 are formed between adjacent radial protrusions 21, so that the outer peripheral top surfaces of the radial protrusions 21 together form a circle separated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com