Glue feeding structure for IMR (In Molding Reprinting) mould

A technology of feeding glue and mould, applied in the field of glue feeding structure for IMR mould, can solve the problems of water leakage of large oblique pins, inconvenient use, blocked waterway, etc., and achieve the effect of preventing water leakage, improving the qualified rate of finished products and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

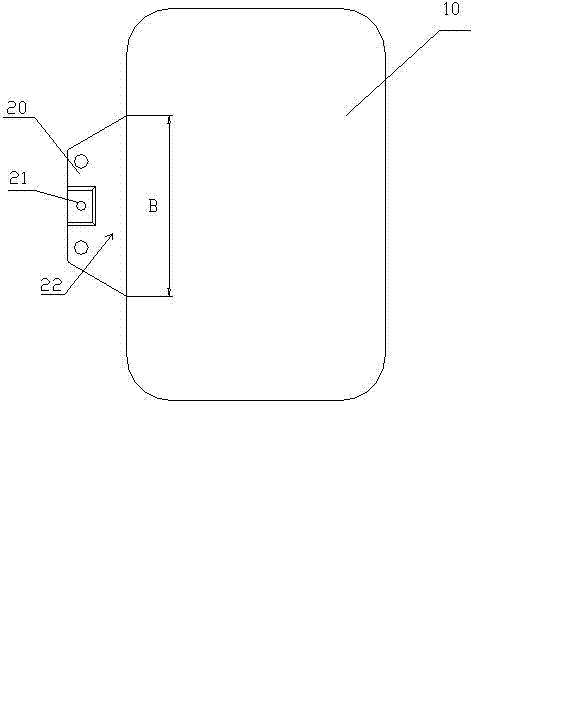

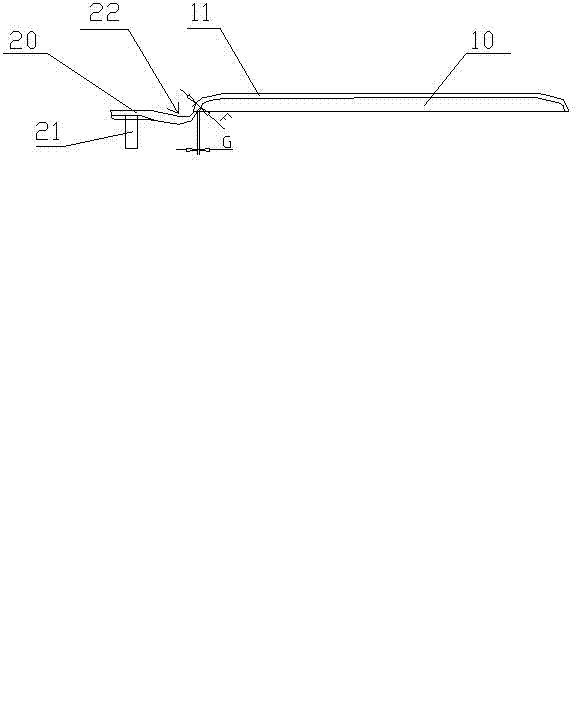

[0015] refer to figure 1 and figure 2 , the IMR mold of the present embodiment uses a glue-in structure, which includes a female template and a male template, a mold core 10 and a mold cavity 11 for a shaped product are arranged on the male template, and a fan-shaped inlet is provided on one side of the cavity 11. A rubber plate 20, on which a downwardly inclined curved groove 22 and a glue inlet 21 communicating with the cavity 11 are arranged on the rubber inlet plate 20, and the glue inlet 21 is connected with the cavity 11 through the curved groove 22 connected.

[0016] In the present invention, the width B of the rubber feed plate 20 is 100-140mm, and it is fan-shaped, and the deepest downward depth of the curved groove 22 is 0.5-1.5mm; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com