Point contact type conveying chain

A conveying chain and point-contact technology, which is used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of affecting the quality of veneers, time-consuming, lack of glue, etc., and achieve a good effect of glue cloth and novel ideas. , Reduce the effect of lack of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with accompanying drawing and embodiment the present invention is described in detail:

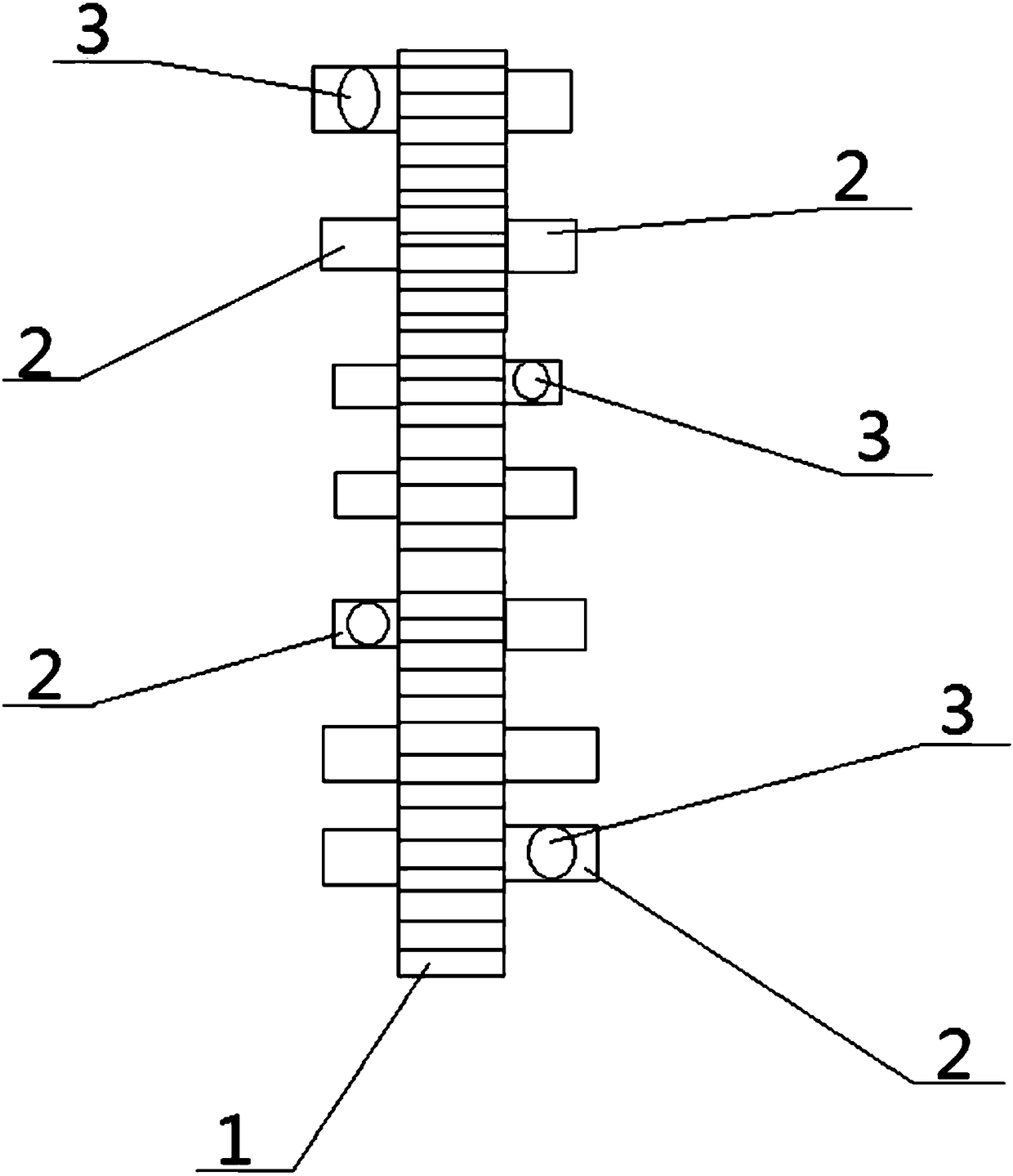

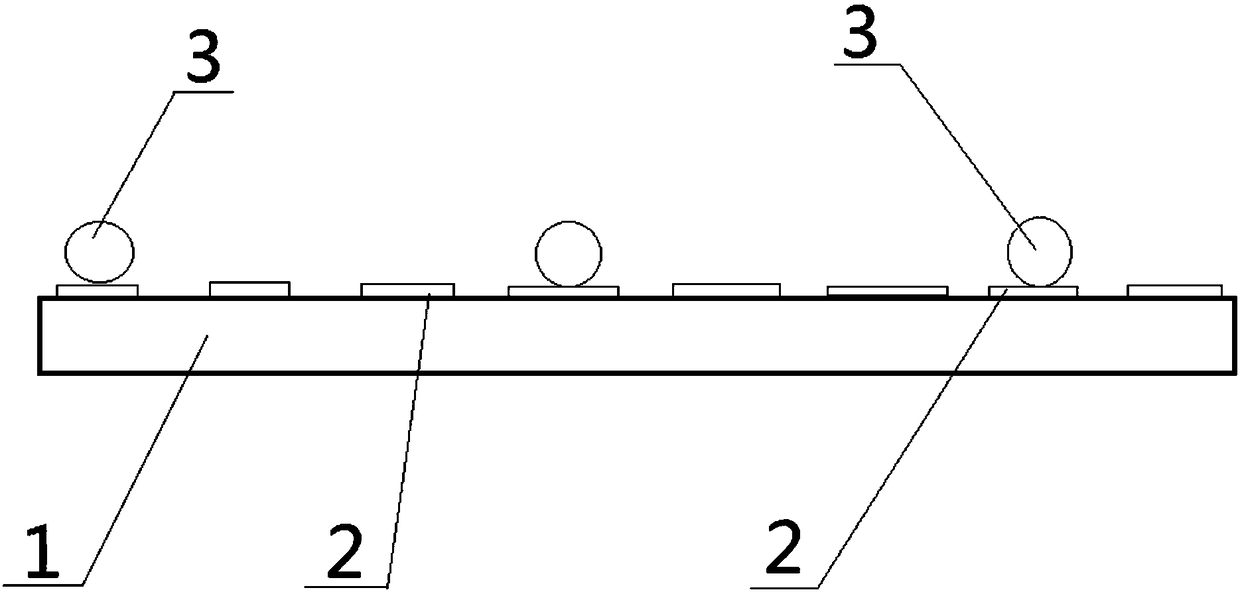

[0022] The present invention is composed of inner chain link (1), connecting piece (2) and steel ball (3).

[0023] figure 1 and figure 2 Shown is the structural representation of the present invention. The present invention is composed of an inner chain link (1), a connecting piece (2) and a steel ball (3), wherein the connecting piece (2) is arranged at the left and right ends of the inner chain link (1), and the steel ball (3 ) is arranged on the connecting piece (2), thus forming a point-contact conveying chain as a whole.

[0024] Application principle of the present invention:

[0025] The present invention is installed on the front rotation system and the rear rotation system of the point-contact automatic board feeding device; then the point-contact automatic board feeding device is placed at the back end of the gluing machine to meet and convey the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com