Method for preparing oxidization ceramic layer on surface of metal substrate and application of method

A metal substrate, surface oxidation technology, applied in the field of medical implant materials, can solve the problems of oxide particle peeling and aggravating wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

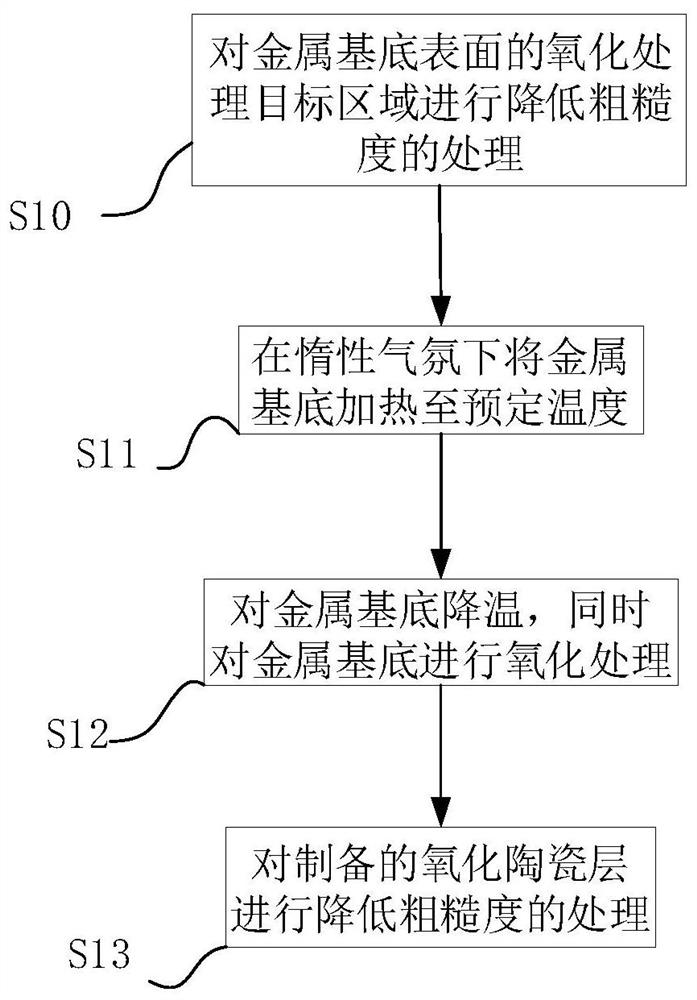

Method used

Image

Examples

preparation example Construction

[0047] In the method for preparing the oxidized ceramic layer on the surface of the metal substrate provided by the present invention, oxidation treatment is carried out to form the oxidized ceramic layer during the cooling process, on the one hand avoiding the accumulation of thermal stress and internal stress generated by oxidation expansion during the heating process, and on the other hand On the one hand, the volume shrinkage of the metal substrate during the cooling process can partially offset the volume expansion caused by oxidation, reducing the total stress of the oxide ceramic layer. Further, immediate cooling can reduce the temperature of the metal substrate near the surface, increase the strength of the metal substrate, enhance the binding force to the oxide ceramic layer, enhance the ability to withstand internal stress, reduce the release of internal stress, and then reduce the Form holes, micro-cracks, or form wavy undulations and other defects at the O / M interfa...

Embodiment 1

[0060] The metal substrate is a zirconium-niobium alloy containing 2.5wt% niobium.

[0061] The zirconium-niobium alloy was ground and polished as sample 1, and the surface roughness of sample 1 was Ra=0.0101um. Place sample 1 in alcohol and ultrasonically clean it for 10 minutes, then ultrasonically clean it in deionized water for 10 minutes, take it out and dry it.

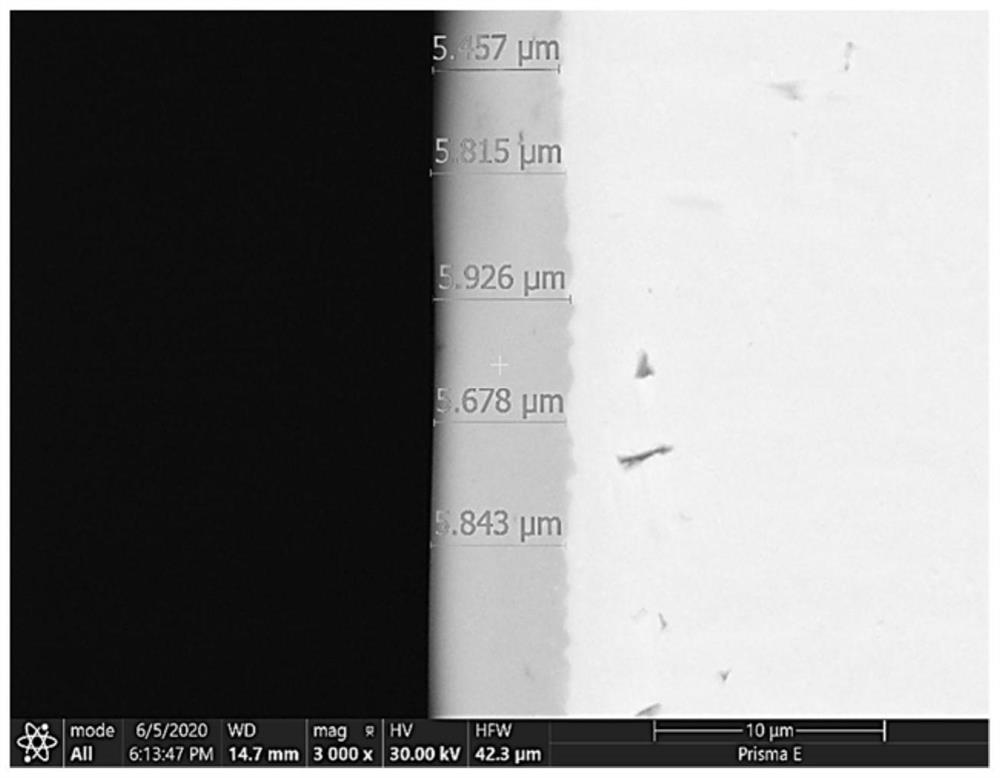

[0062] The dried sample 1 was placed in an atmosphere furnace, fed with argon gas, and heated to 700°C, and the heating was stopped.

[0063] Introduce a mixture of argon and oxygen into the atmosphere furnace, and control the temperature in the atmosphere furnace to drop at a rate of 10°C / min until the temperature in the atmosphere furnace drops to room temperature (about 25°C), take out sample 1, and measure Its surface roughness Ra=0.0232um. In this embodiment, the flow rate of the mixed gas into the atmosphere furnace is 500ml / min. In terms of volume percentage, the initial content of oxygen in the mixed ...

Embodiment 2

[0069] The metal substrate is a zirconium-niobium alloy containing 2.5wt% niobium.

[0070] The zirconium-niobium alloy was ground and polished as sample 2, and the surface roughness of sample 2 was Ra=0.0136um. Place sample 2 in alcohol and ultrasonically clean it for 10 minutes, then ultrasonically clean it in deionized water for 10 minutes, take it out and dry it.

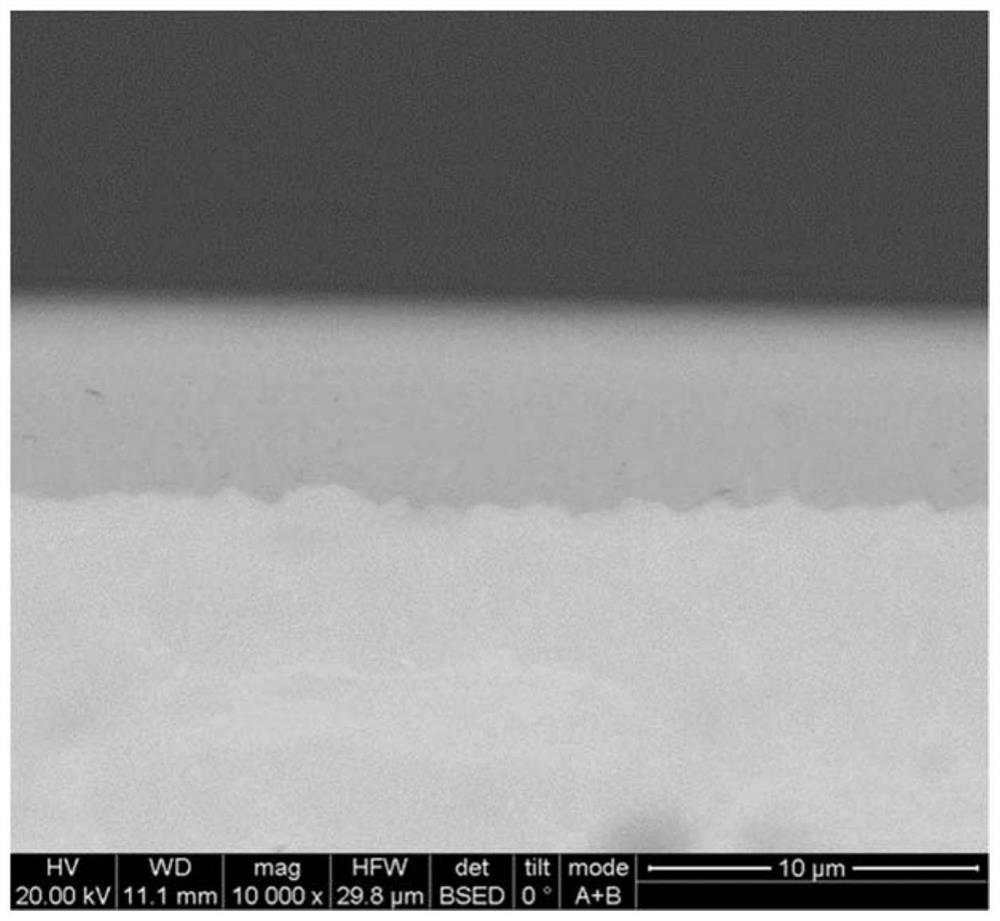

[0071] The dried sample 2 was placed in an atmosphere furnace, fed with argon gas, and heated to 700°C, and the heating was stopped.

[0072] A mixture of argon and oxygen was introduced into the atmosphere furnace, and the temperature in the atmosphere furnace was controlled to drop at a rate of 5°C / min until the temperature in the atmosphere furnace dropped to 150°C, and sample 2 was taken out. After the sample was cooled to room temperature, the surface roughness Ra=0.0310um was measured. In this embodiment, the flow rate of the mixed gas into the atmosphere furnace is 1000ml / min. In terms of volume percen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com