Surface treatment process of corrosion-resistant alloy seamless steel tube

A seamless steel pipe and surface treatment technology, applied in the field of xxx, can solve the problems of easily damaged protective layers, achieve the effect of ensuring production quality and avoiding damage to the paint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

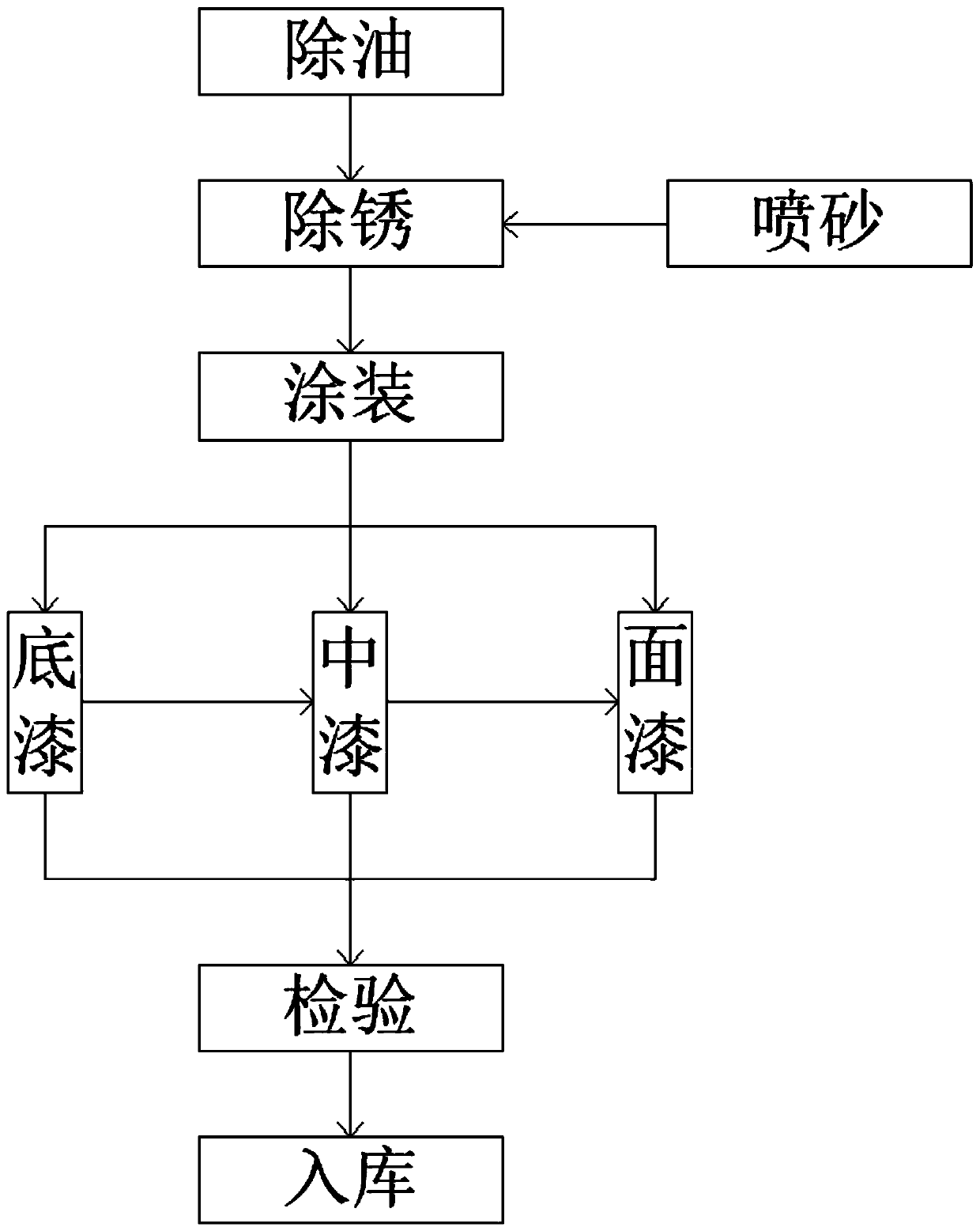

[0024] see figure 1 , the present invention provides a technical solution for the surface treatment process of corrosion-resistant alloy seamless steel pipes: a surface treatment process for corrosion-resistant alloy seamless steel pipes, the steps are as follows:

[0025] Step 1: Degreasing: In the seamless steel pipe processing operation room, the seamless steel pipe is put into the degreasing area by the mechanical arm for degreasing. The degreasing time in the oil area is 2 minutes, and the standard is clean;

[0026] Step 2: Derusting: Before derusting, it is necessary to preheat the seamless steel pipe to be derusted and sandblasted, and uniformly heat the seamless steel pipe through the ring heater to ensure that the temperature of the bottom and side of the steel pipe should be consistent, and the heating temperature should be no The product specification of the seam steel pipe is used as the guideline, and the derusting operation is carried out by sandblasting. The ...

Embodiment 2

[0033] see figure 1 , the present invention provides a technical solution for the surface treatment process of corrosion-resistant alloy seamless steel pipes: a surface treatment process for corrosion-resistant alloy seamless steel pipes, the steps are as follows:

[0034] Step 1: Degreasing: In the seamless steel pipe processing operation room, the seamless steel pipe is put into the degreasing area by the mechanical arm for degreasing. The degreasing time in the oil area is 2 minutes, and the standard is clean;

[0035] Step 2: Derusting: Before derusting, it is necessary to preheat the seamless steel pipe to be derusted and sandblasted, and uniformly heat the seamless steel pipe through the ring heater to ensure that the temperature of the bottom and side of the steel pipe should be consistent, and the heating temperature should be no The product specification of the seam steel pipe is used as the guideline, and the derusting operation is carried out by sandblasting. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com