Foundation structure for tower-like construction

A technology for basic structures and structures, applied in the field of basic structures, can solve problems such as damage to concrete and cracks in concrete, and achieve the effects of preventing breakage, preventing concrete breakage, and facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, the basic structure of the tower structure of this invention is demonstrated concretely based on the preferred embodiment shown in figure.

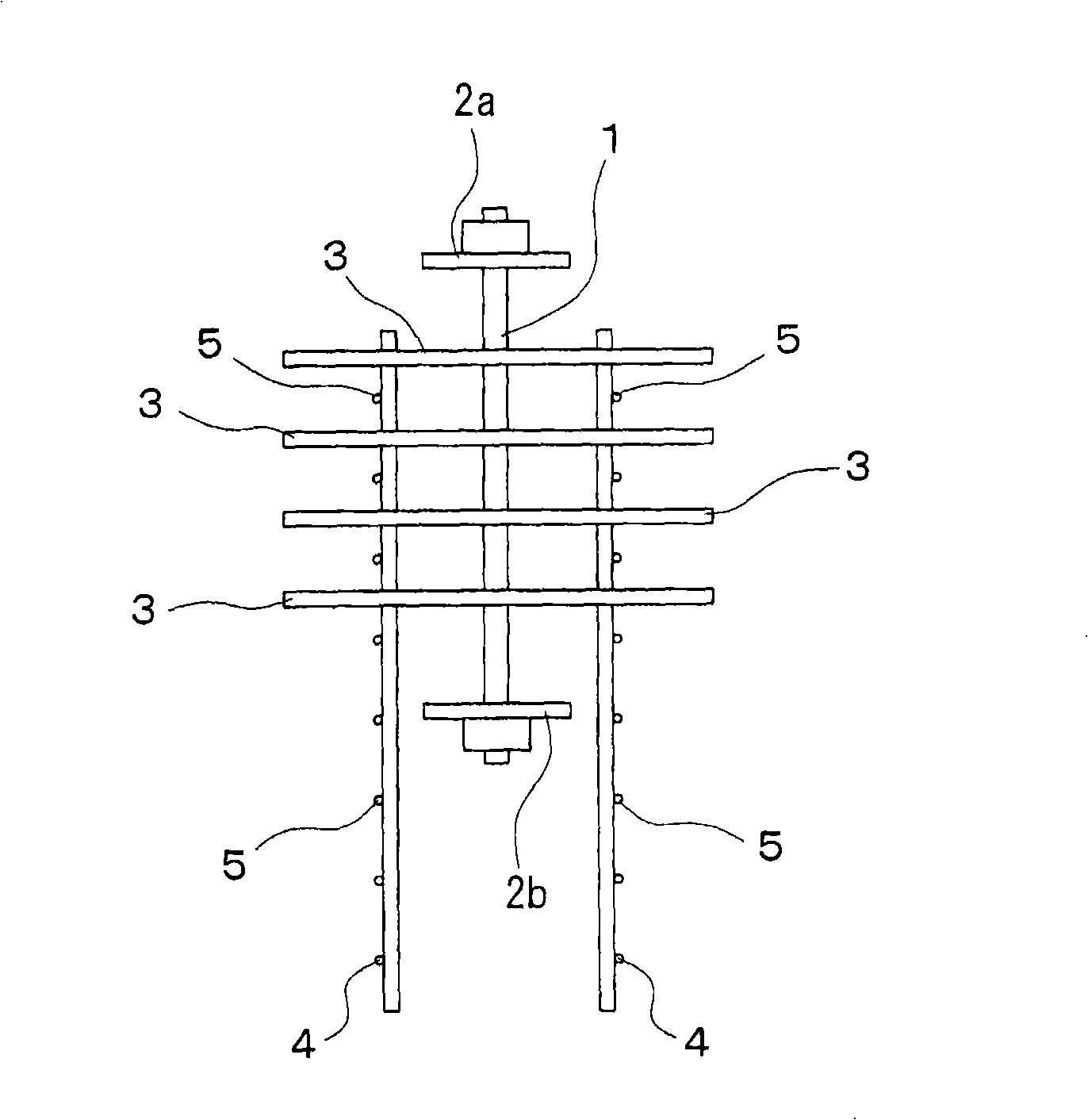

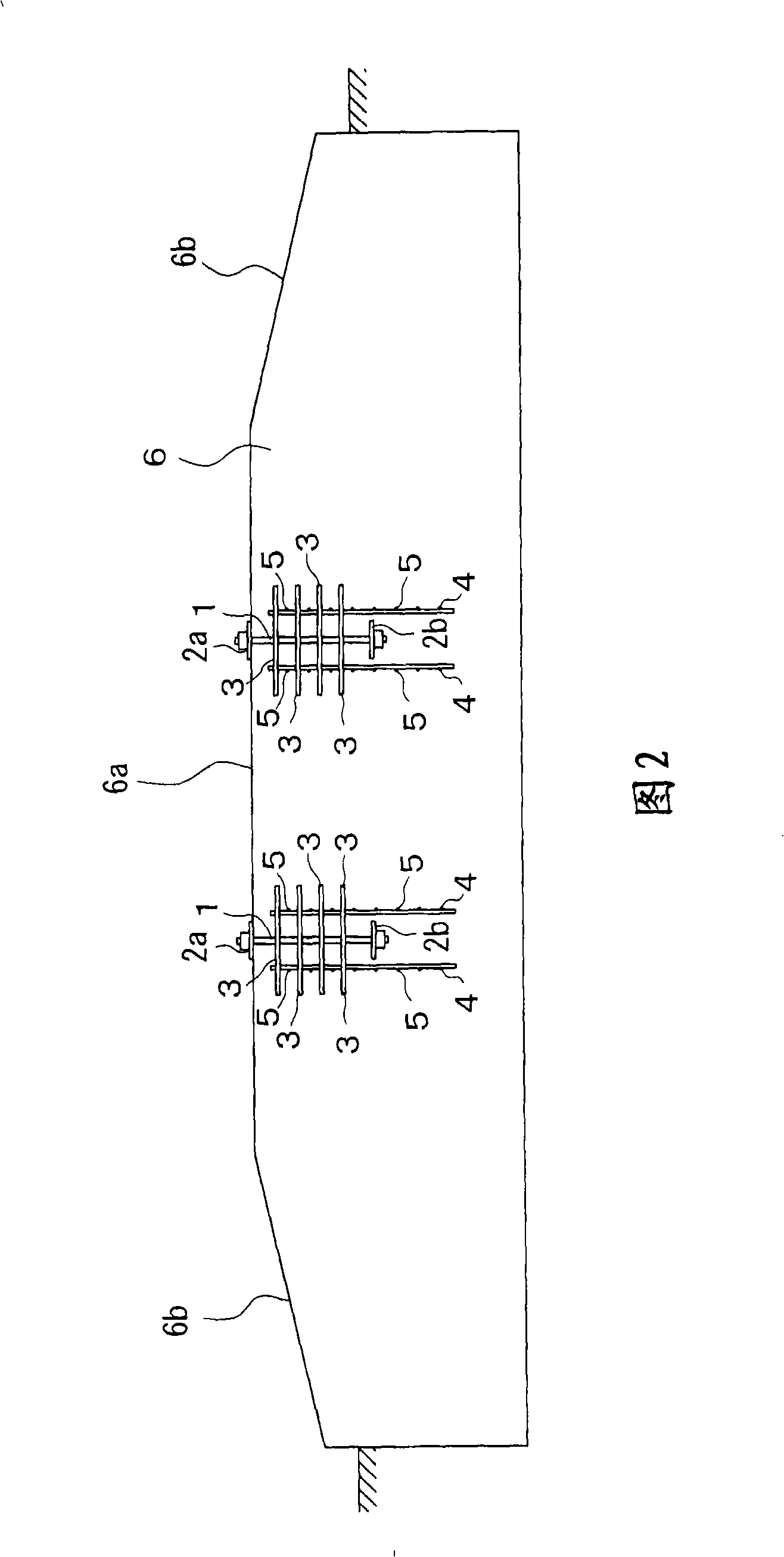

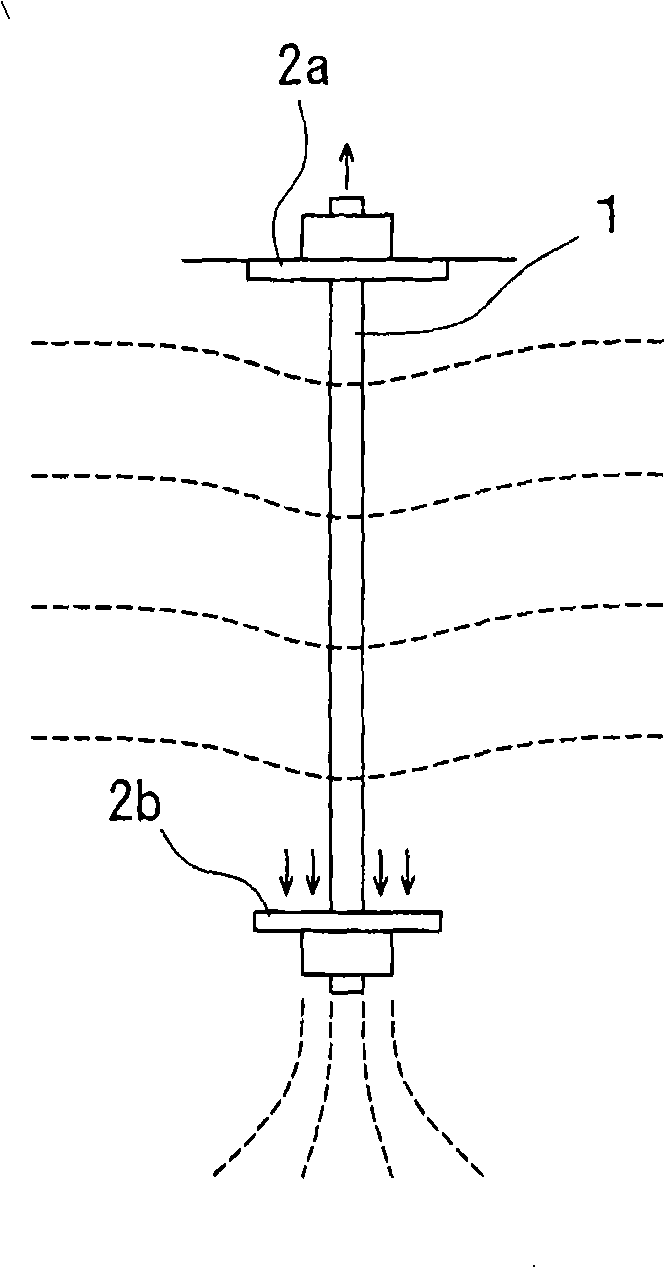

[0045] like figure 1 As shown, in this foundation structure, a tower-shaped structure such as a windmill tower is fixed to the foundation by using the unbonded anchor bolt 1 introducing prestress. The non-adhesive anchor 1 is prestressed and straddled on the base plate 2a and the anchor plate 2b. In the direction intersecting with the longitudinal direction of the unbonded anchor bolt 1, an appropriate number of horizontal steel bars 3 are arranged, and longitudinal steel bars 4 in a direction parallel to the longitudinal direction of the unbonded anchor bolt 1 are arranged. .

[0046] For example, in a wind power generation tower, since the hollow cylinders are stacked, the non-adhesive anchors 1 are arranged at appropriate intervals along the arc of the hollow cylinders. In addition, in figure 1 In the figure, al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com