Inorganic material outer wall heat insulation and preservation board and production method thereof

A technology of heat insulation and inorganic materials, applied in the field of building exterior wall materials, can solve the problems of fire hazards of exterior wall heat insulation materials, square stickers are easy to fall, etc., and achieve high construction efficiency and simple and easy production methods , the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

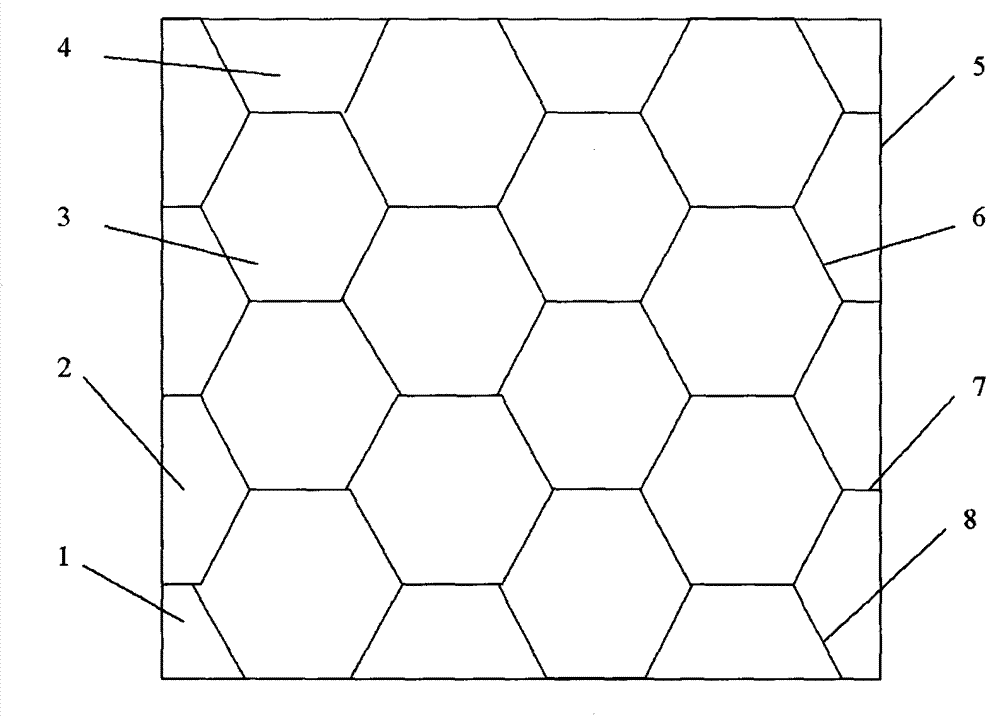

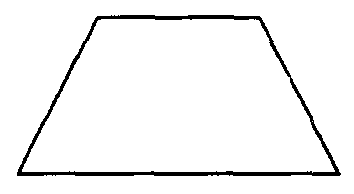

[0042] See figure 1 . Outer mold 5 adopts square, and internal mold is made of regular hexagonal dividing plate 6, short dividing plate 7 and long dividing plate 8. The length of short dividing plate 7 is half of the side length of regular hexagonal dividing plate 6, so just can obtain side-dividing edge block 2 (the midpoint of two opposite sides separates), the length of long dividing plate 8 is regular hexagonal simultaneously The length of the side of dividing plate 6, so just can obtain corner-dividing side block 4 (the midpoint of two opposite sides separates).

[0043] Use this mold according to the method described in the present invention, can produce corner block 1, split edge block 2, main block 3 and split corner edge block 4. Their structures all form closed foam cells inside, with a dry bulk density of 200kg / m 3 , Foam concrete with a thickness of 3cm.

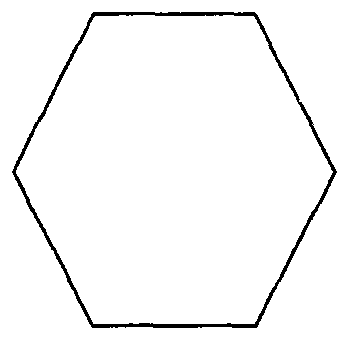

[0044] figure 2 The shown regular hexagonal main block is used to pave the entire wall surface of the ou...

Embodiment 2

[0047] See Image 6 . The outer mold 5 adopts a square shape, and the inner mold is composed of a regular hexagonal partition 6, a vertical partition 11 perpendicular to the outer mold 5 and an inclined partition 8 not perpendicular to the outer mold 5. The length of the vertical dividing plate 11 is equal to the side length of the regular hexagonal dividing plate 6, so that the chamfered edge block 9 can be obtained, and the length of the oblique dividing plate 8 is also equal to the side length of the regular hexagonal dividing plate 6, so that the points can be obtained. Corner edge block 4 (two opposite sides separated by midpoint). In fact, the oblique partition 8 here is the same as the long partition 8 in Embodiment 1.

[0048] Use this mold according to the method described in the present invention, can produce corner block 10, chamfered edge block 9, main block 3 and sub-angular edge block 4. Their structures all form closed foam cells inside, with a dry bulk densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com