Device for charging dry air or nitrogen gas into semiconductor wafer storage container and wafer static charge removing apparatus utilizing the device

A technology of dry air and storage containers, which is applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems that cannot be completely solved, cannot completely prevent semiconductor wafer static electricity, dust flying, etc., and achieve the effect of preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

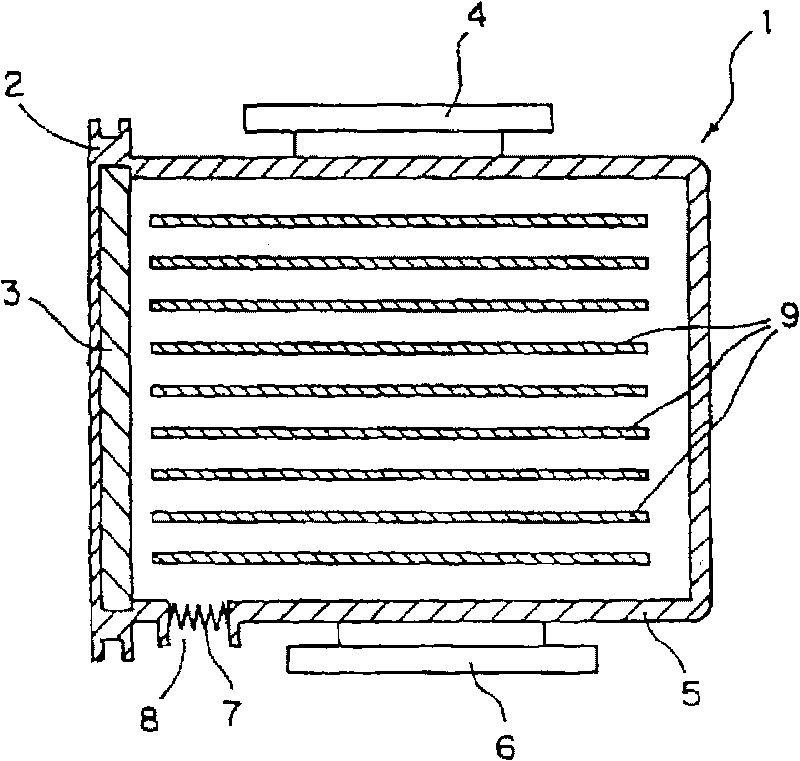

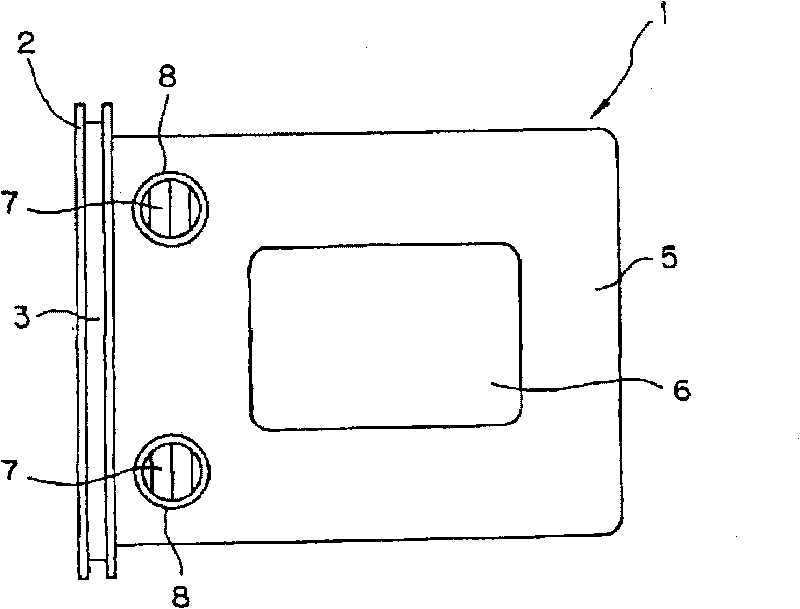

[0051] The filling device of dry air or nitrogen in Embodiment 1 of the present invention will be described in detail with reference to the drawings. figure 1 is a longitudinal sectional view of a semiconductor wafer storage container used in the present invention, figure 2 is the bottom view of the figure. Such as figure 1 , figure 2 As shown, on the semiconductor wafer storage container 1, an openable and closable cover 3 provided with a cover flange 2 is installed on the front surface, and a lifting hook 4 for lifting the semiconductor wafer storage container 1 is installed on the top, and furthermore, on the bottom plate Legs 6 for mounting on a not-shown mounting table or the like, and a plurality of breathing ports 8 provided with PTFE filters 7 are provided on 5 .

[0052] The semiconductor wafer 9 is accommodated in the above-mentioned semiconductor wafer storage container 1, and the semiconductor wafer 9 is processed by a process device (not shown). Adhesive che...

Embodiment 2

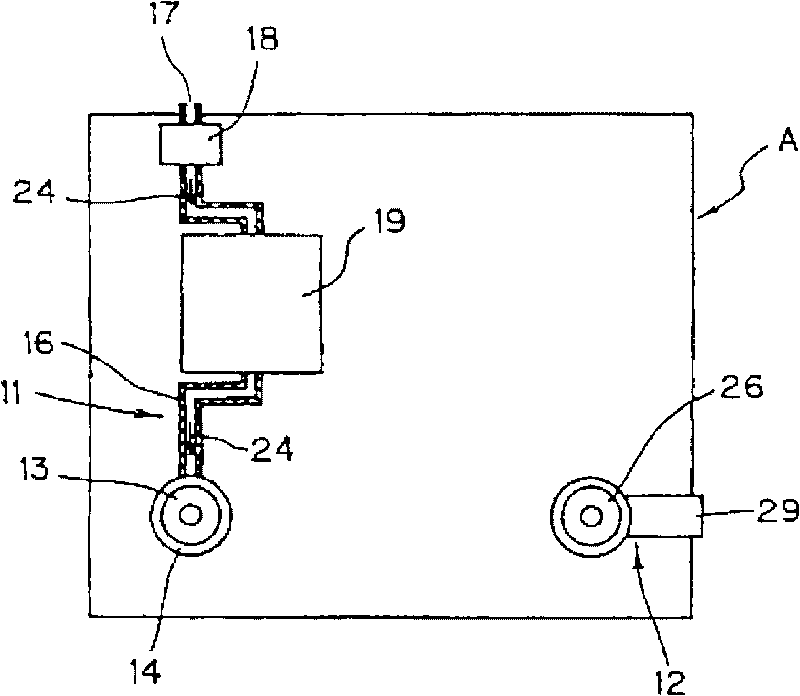

[0066] As a second embodiment of the present invention, a static eliminator using a filling device of dry air or nitrogen gas obtained by the above configuration will be described in detail with reference to the drawings.

[0067] Figure 8 It is a plan view of the static elimination device using the dry air or nitrogen filling device of the present invention, Figure 9 It means that the antistatic device is installed on the figure 1 , figure 2 A longitudinal cross-sectional view of the state of the semiconductor wafer storage container shown. Such as Figure 8 , Figure 9 As shown, the static eliminator B that removes the static electricity carried by the semiconductor wafer 9 in the semiconductor wafer storage container 1, the dry air / nitrogen supply unit 11 that supplies dry air or nitrogen in the above-mentioned dry air or nitrogen filling device A, Used as the ionized dry air / ionized nitrogen gas supply part 11a, and the used dry air or nitrogen gas discharge part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com