Gas-liquid separator and refrigeration device with the gas-liquid separator

A gas-liquid separator, gas-liquid technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem that the refrigeration device cannot operate stably, and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

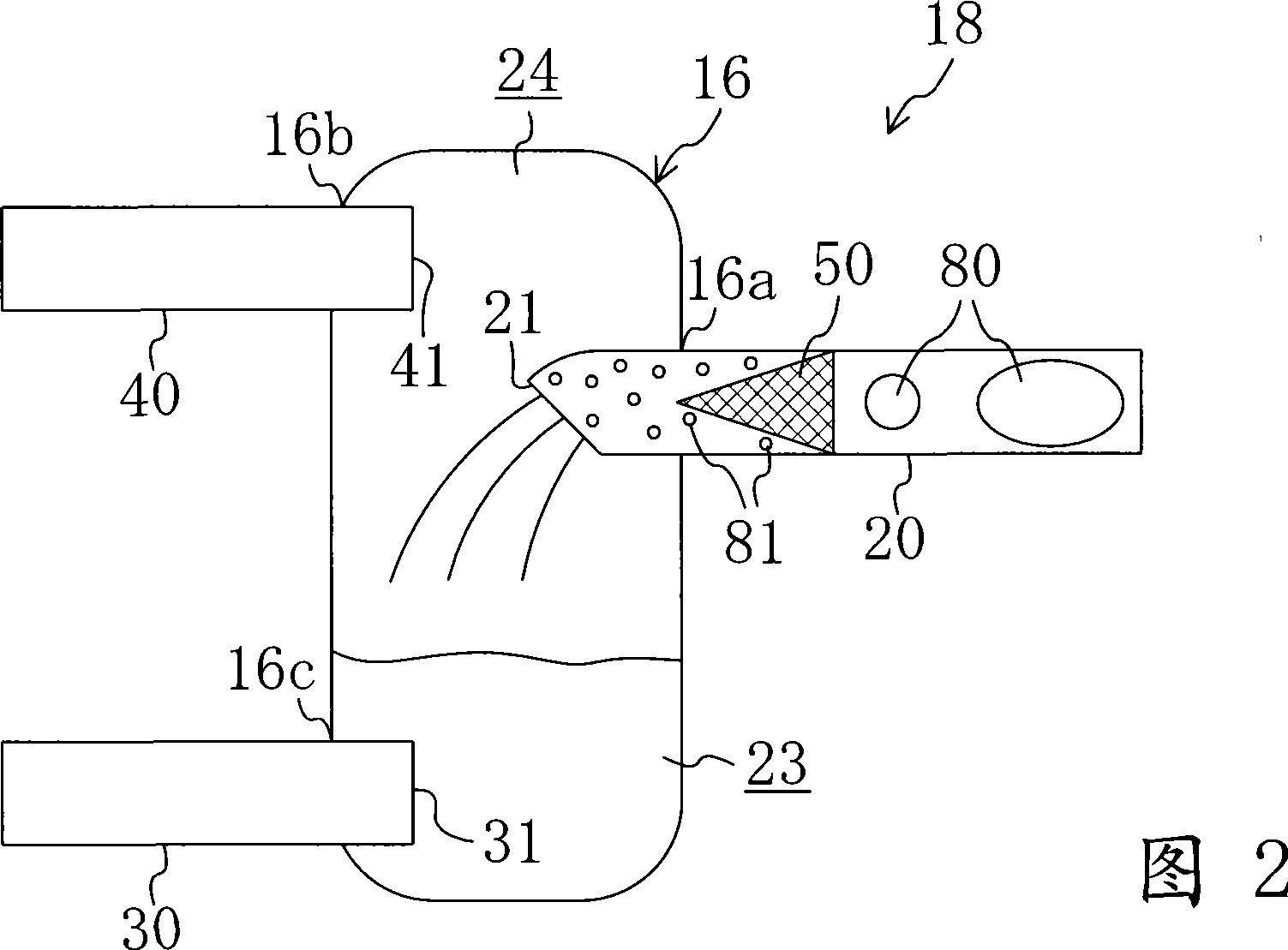

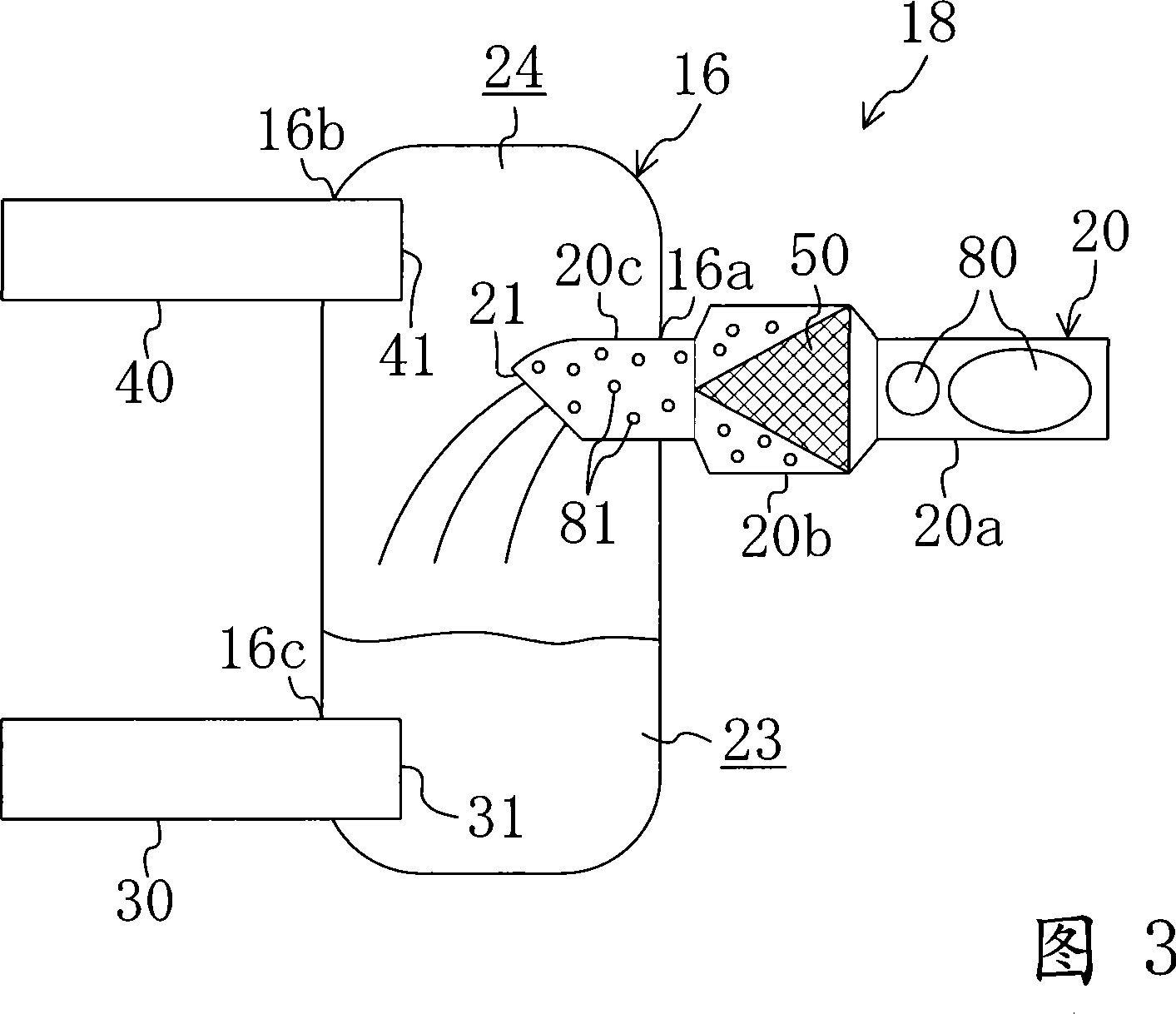

Embodiment approach 1

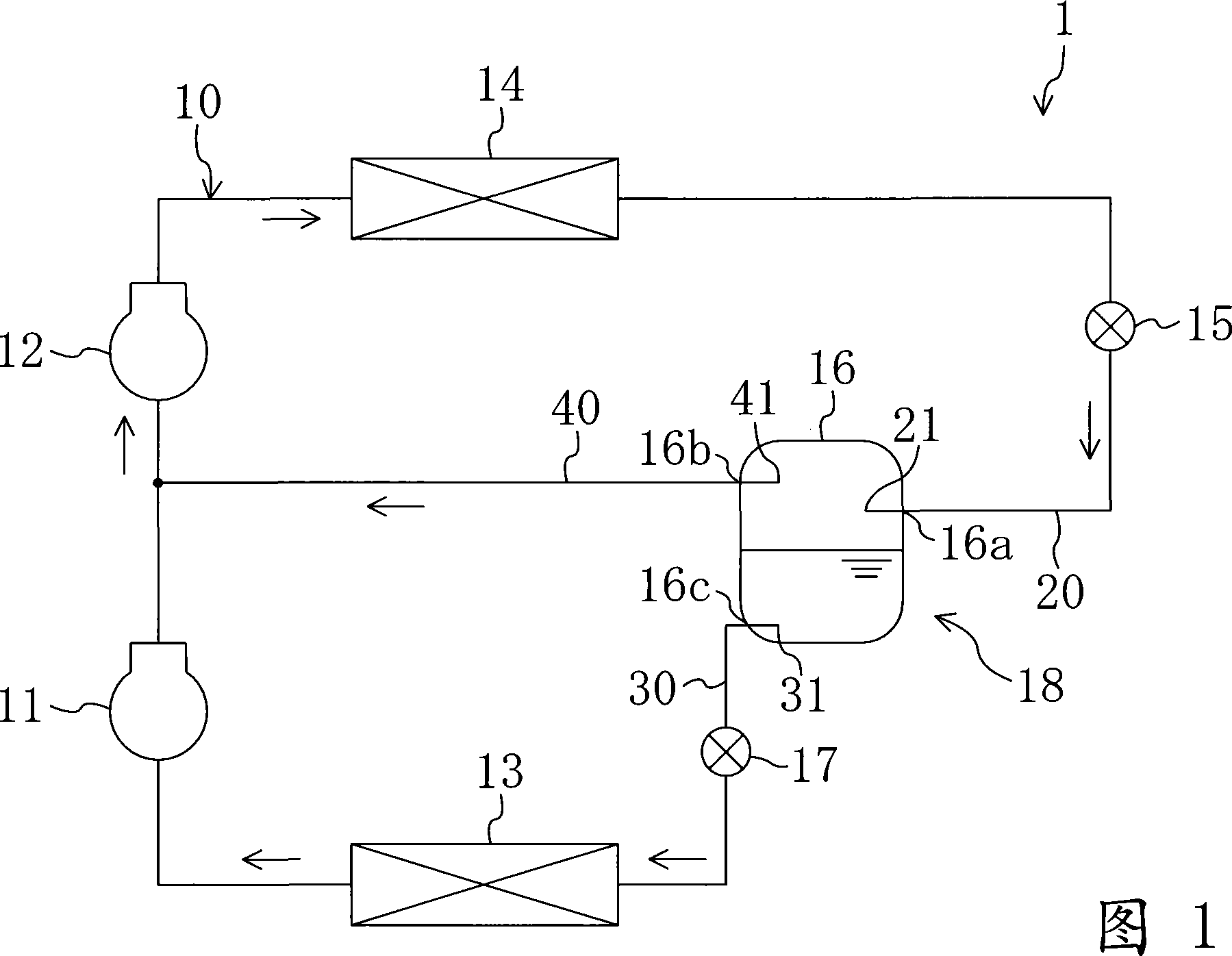

[0082] As shown in FIG. 1, the refrigeration apparatus 1 of this embodiment is an apparatus which performs refrigeration operation in a refrigerator. The refrigerating device 1 includes a refrigerant circuit 10 that performs a two-stage compression and two-stage expansion refrigeration cycle.

[0083]

[0084] The refrigerant circuit 10 includes a low-stage compressor 11, a high-stage compressor 12, a refrigeration heat exchanger 13, an outdoor heat exchanger 14, a main expansion valve 17, an intermediate expansion valve 15, and a gas-liquid separator as a feature of the present invention. 18.

[0085] The discharge side of the low-stage compressor 11 is connected to the suction side of the high-stage compressor 12 . The low-stage compressor 11 and the high-stage compressor 12 are constituted by, for example, scroll compressors.

[0086] The refrigeration heat exchanger 13 is installed in the refrigerator, and the refrigeration heat exchanger 13 is configured as an evapora...

Embodiment approach 2

[0126] Same as the first embodiment, this embodiment is a refrigeration device that includes a refrigerant circuit that performs a two-stage compression and two-stage expansion refrigeration cycle and performs refrigeration operation in the storehouse. Only the configuration of the gas-liquid separator 18 in the refrigerant circuit is the same as The first embodiment is different.

[0127] Such as Figure 5 As shown, the gas-liquid separator 18 of this embodiment is formed such that the dimension in the longitudinal direction on the horizontal plane of the container body 16 is larger than the dimension in the vertical direction. In addition, the mesh member 50 which is a refiner is not provided in the inflow pipe 20 of the said gas-liquid separator 18. As shown in FIG.

[0128] Specifically, the container body 16 of the gas-liquid separator 18 is installed so that the cylindrical container body 16 of the first embodiment is placed horizontally so that the axial direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com