Light conductive board and the backlight module possessing same

A backlight module and light guide plate technology, applied in the optical field, can solve problems such as poor picture resolution, increased display cost, and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

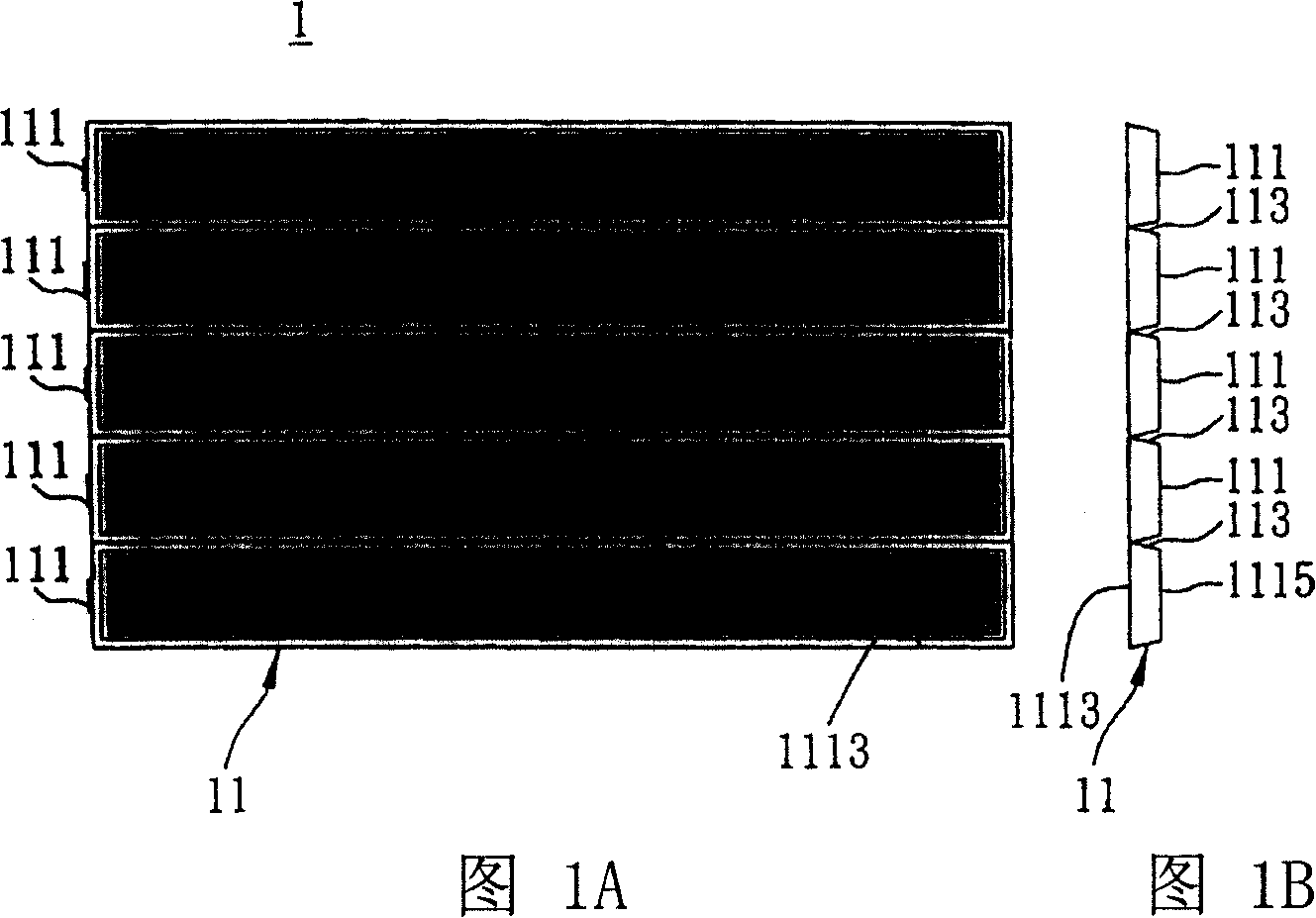

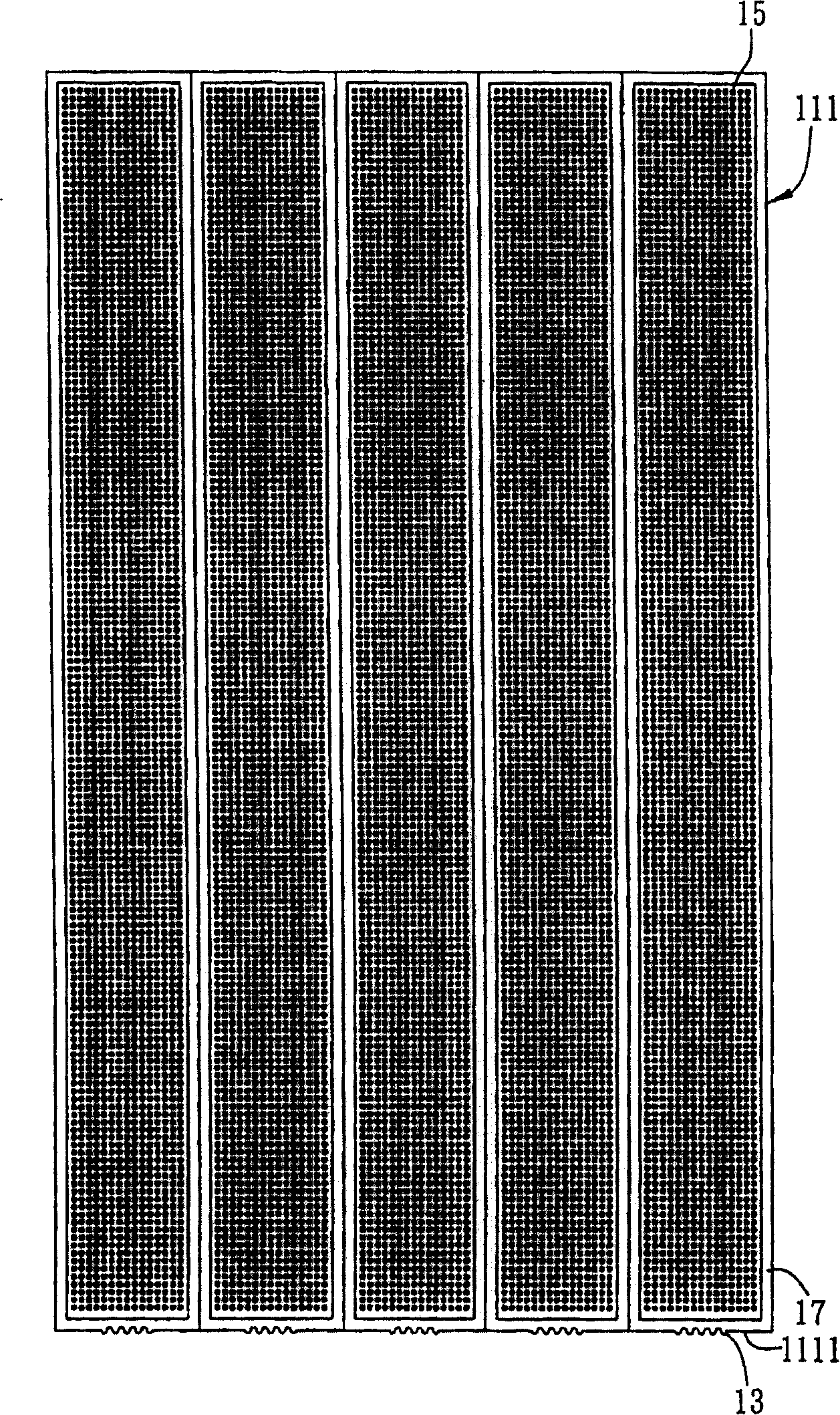

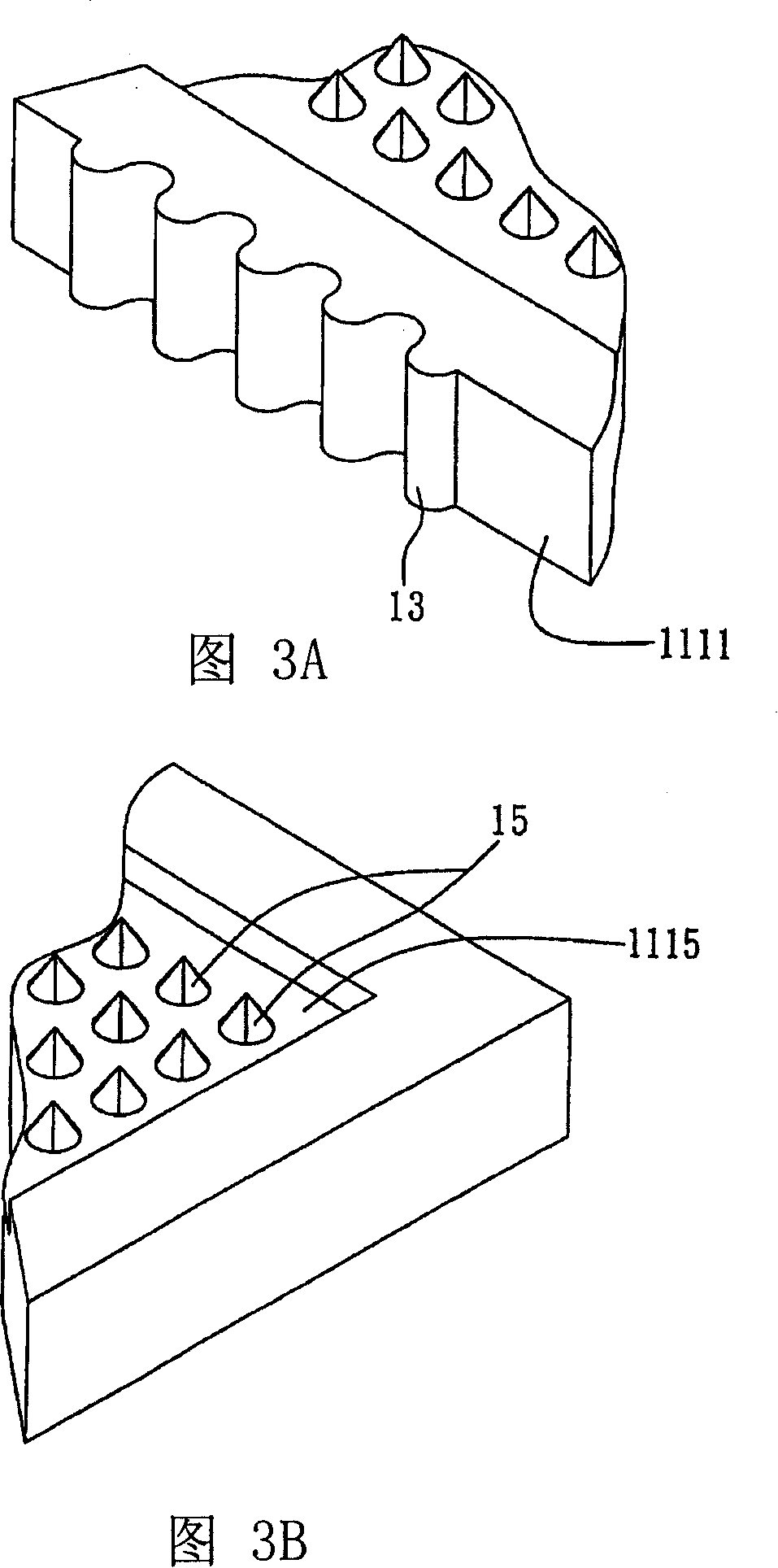

[0033] 1A to 3B are drawings drawn according to the first embodiment of the light guide plate of the present invention, Figure 4 is a schematic diagram showing the structure of a backlight module to which the light guide plate according to the first embodiment of the present invention is applied.

[0034] Please refer to Figure 1A, Figure 1B and figure 2 , they are schematic diagrams showing the structure of the light guide plate of this embodiment, wherein Fig. 1A and Fig. 1B are schematic diagrams showing the structure of the first embodiment of the light guide plate of the present invention, and Fig. 1B is a side view of Fig. 1A, figure 2 It is a schematic diagram showing a partial bottom view 1A of the light guide plate. As shown in the figure, the light guide plate 1 includes a light-transmitting substrate 11 , a grating structure 13 , and a light-scattering structure 15 .

[0035] The light-transmitting substrate 11 has a timing spacer 113 that divides the light-transm...

no. 2 example

[0051] Figure 5A to Figure 7 The drawings are drawn for the second embodiment of the light guide plate and the backlight module with the light guide plate according to the present invention. Wherein, the same or similar elements as those of the first embodiment are represented by the same or similar element symbols, and detailed descriptions are omitted to make the description of this case clearer and easier to understand.

[0052] The biggest difference between the second embodiment and the first embodiment is that in the first embodiment, multiple timing intervals are provided on the light-transmitting substrate to distinguish the light-transmitting substrate into multiple regions, while in the light guide plate of the second embodiment, The light-transmitting substrate is composed of a plurality of regions arranged at intervals.

[0053] Such as Figure 5A The shown light guide plate 1' includes a light-transmitting substrate 11' composed of five regions 111'. Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com