Electric impulse auxiliary superplastic forming device and method

A technology of superplastic forming and electric pulse, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high energy consumption, low energy utilization rate, long heating time and other problems of superplastic inflatable forming process, to avoid Effects of heat loss, reduced deformation resistance, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

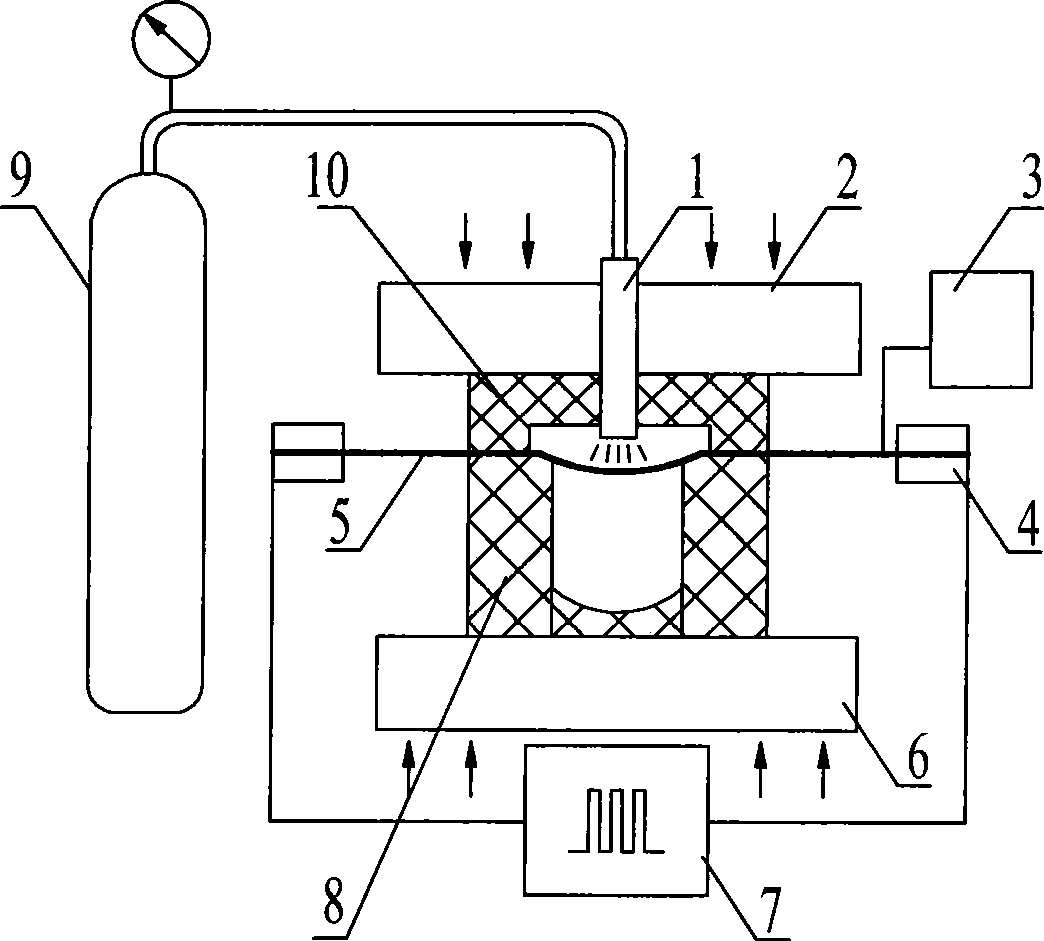

[0013] Specific implementation mode one: combine figure 1 Describe this embodiment, the device of this embodiment is made up of high-frequency pulse power supply 7, air pressure device, insulating mold, indenter and blank clamping electrode; 8 are respectively placed on the upper and lower sides of the blank 5 to be formed, the forming part of the blank 5 to be formed is placed in the cavity of the upper mold 10 and the lower mold 8, and the blank 5 to be formed separates the upper mold 10 and the lower mold 8 into two Cavity, the outer edge of the blank 5 to be formed is placed outside the insulation mold, the pressure head is closed and pressed against the insulation mold and the blank 5 to be formed, the air outlet of the air pressure device penetrates the pressure head and the upper part of the insulation mold and is placed in the cavity of the insulation mold The two chucks 4 of the blank clamping electrode clamp the outer edge of the blank 5 to be formed, and the electro...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and the specific embodiment is that an infrared thermometer 3 is added, and the probe of the infrared thermometer 3 is arranged on the blank 5 to be formed, and the blank to be formed is measured in real time by the infrared thermometer 3 5 temperature. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0015] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 or 2 is that the insulating mold is made of ceramic material, and the insulating ceramic mold will not divert the current flowing through the blank 5 to be formed, reducing energy loss. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com