A method for enduing high-vanadium high-cobalt high-speed steel with superplasticity property

A high-vanadium, high-cobalt, high-speed steel technology is applied in the field of making high-vanadium, high-cobalt high-speed steel obtain superplastic properties, and can solve the problems of inability to fully utilize materials, narrow range of deformation speed, and very high precision requirements for temperature control equipment and forming equipment, etc. problem, to achieve the effect of great economic significance and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The composition (wt%) of the high-vanadium high-cobalt high-speed steel master alloy that the present invention adopts is: C1.31, W5.11, Mo4.16, Cr4.33, V3.12, Co6.64, Si0.06, Mn0.19 , P0.022, S0.011.

[0033] Spray forming, the operation process of spray forming is: put the above-mentioned high-speed steel master alloy material (cast rod) into the induction furnace to heat and melt; keep it at a temperature of about 150°C higher than the melting point for a period of time, so that the temperature and composition of the melt can be uniform ; Then spray the melt with high-pressure nitrogen gas to atomize it into fine droplets, fly and deposit on the collecting substrate, complete solidification and form a block. The diameter of the catheter used in the spraying process is 4.5mm, the atomizing nitrogen pressure is 2.5MPa, the spraying distance is 350mm, the rotation speed of the substrate is 10rpm, and the gas / melt flow ratio (G / M) is about 0.40m 3 / kg.

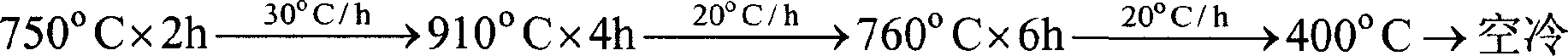

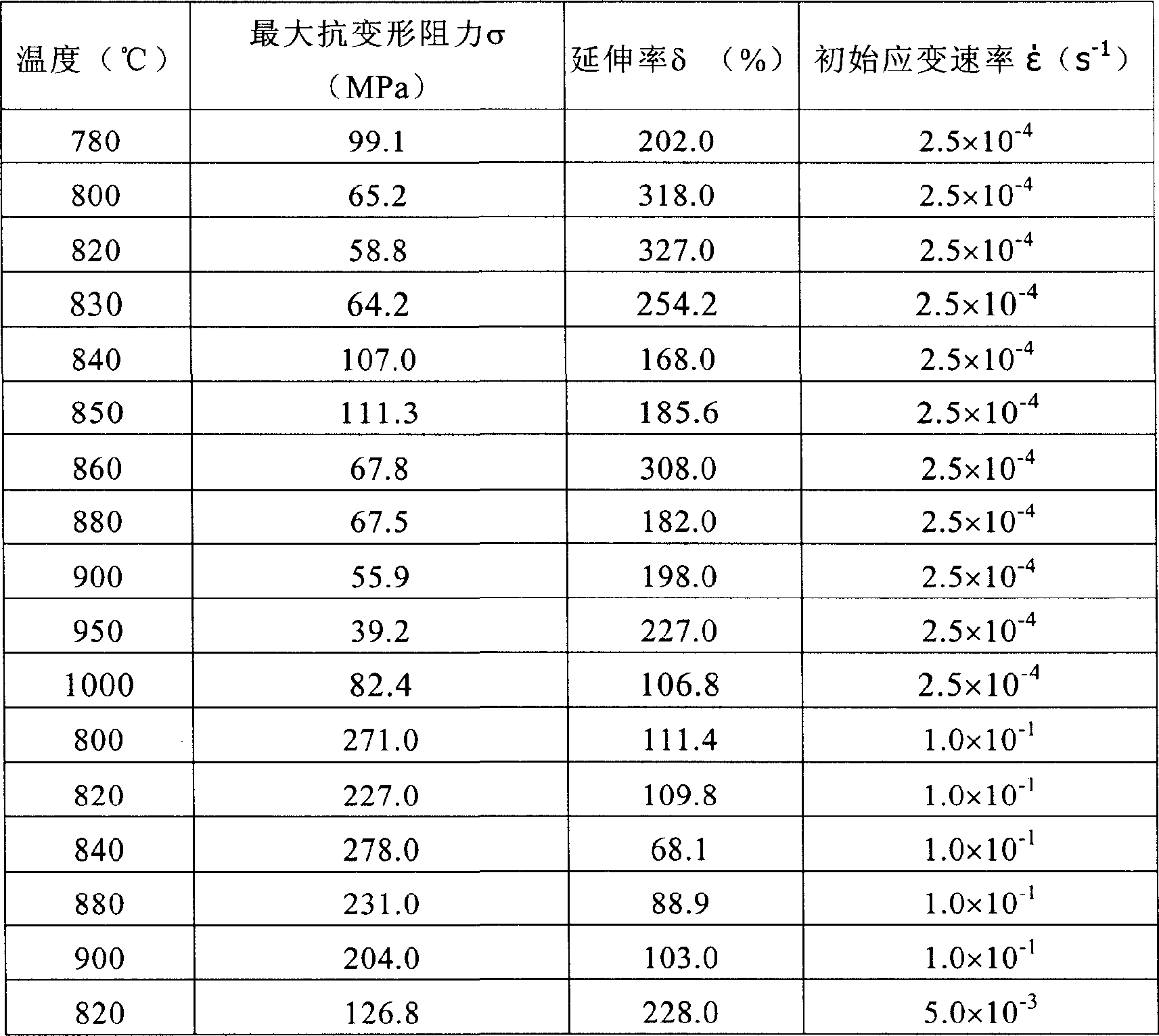

[0034] For hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com