Amorphous alloy precision parts superplastic drop-forging shaper and method thereof

A technology of superplastic die forging and amorphous alloys, applied in metal processing equipment, etc., can solve the problems of less research on superplastic forming of fine parts and no research reports on large amorphous alloys, so as to reduce the process flow and process turnaround time, reduced forming pressure, dimensional stability and precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

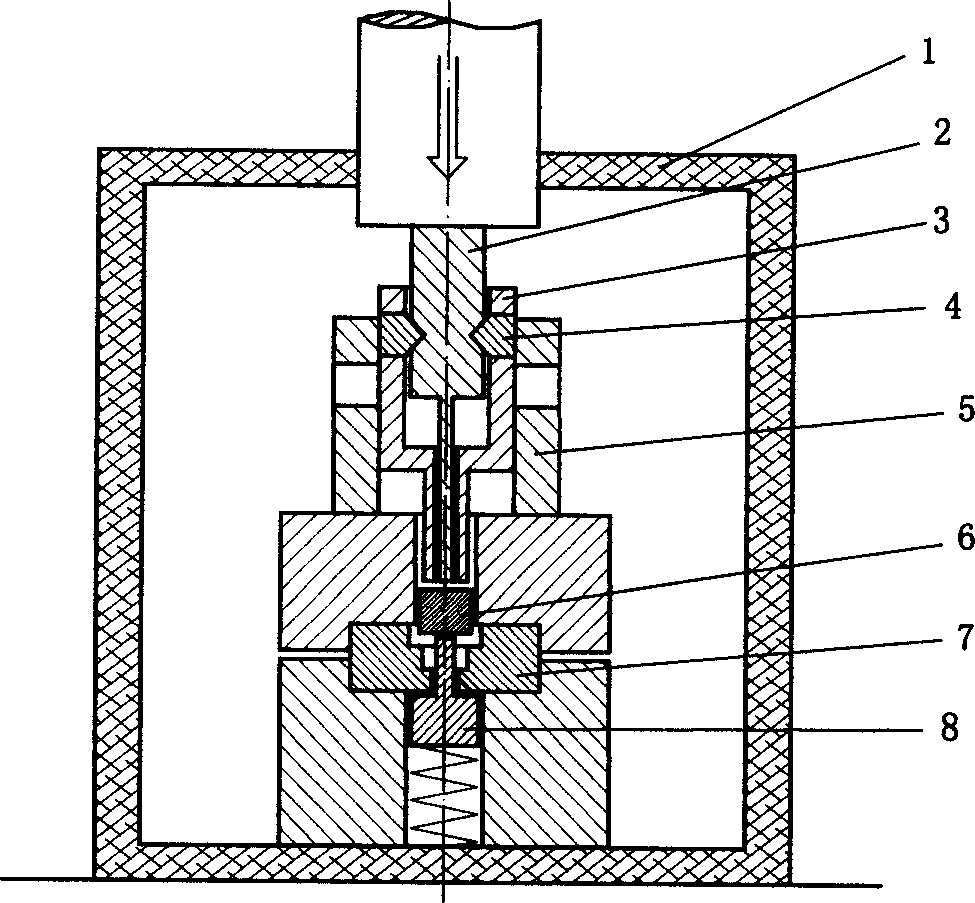

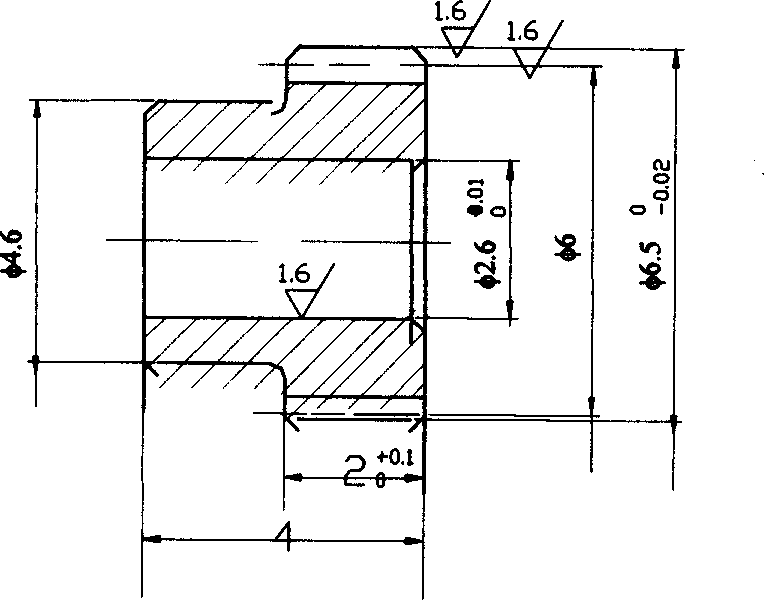

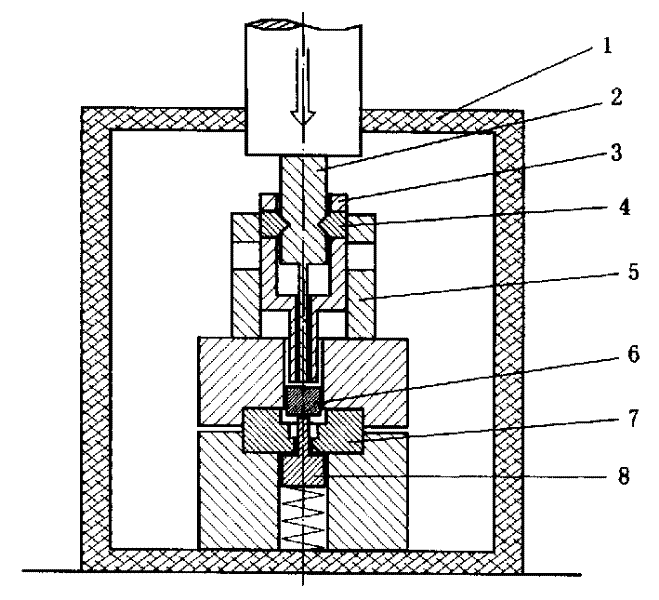

[0014] The forming object is used on an instrument such as attached figure 2 For the spur gear with hub shown, the hub wall thickness is 1mm, the inner hole diameter is φ2.6mm, the dimensional tolerance is 0~+0.01mm, the surface roughness is 1.6μm; the addendum circle diameter is φ6.5mm, and the dimensional tolerance is -0.02~ 0mm, tooth surface roughness 1.6μm. The part is required to have high strength, high wear resistance and high corrosion resistance. For this purpose, Zr with a diameter of φ5mm is used 41.25 Ti 3.75 Cu 12.5 Ni 10 be 22.5 Large amorphous alloy rods are used as forming materials (compression yield strength at room temperature is greater than 1.9GPa, and Vickers hardness is greater than 5.0GPa) for superplastic forming. The forming temperature is 380~395℃, the strain rate is 1×10 -3 ~5×10 -4 the s -1 . The forming process is carried out in two steps: the first step is to use the integral flat punch to make the metal initially fill the tooth shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com