Method for preparing magnesium alloy section bar by continuous corner shearing and squeezing shaping and mold

A magnesium alloy and corner technology, applied in metal extrusion dies, metal extrusion control equipment, metal extrusion, etc., can solve the problems that the degree of refinement cannot reach 1/2, the production efficiency is reduced, and the product quality is reduced. , to achieve the effect of improving smoothness, less slippage and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

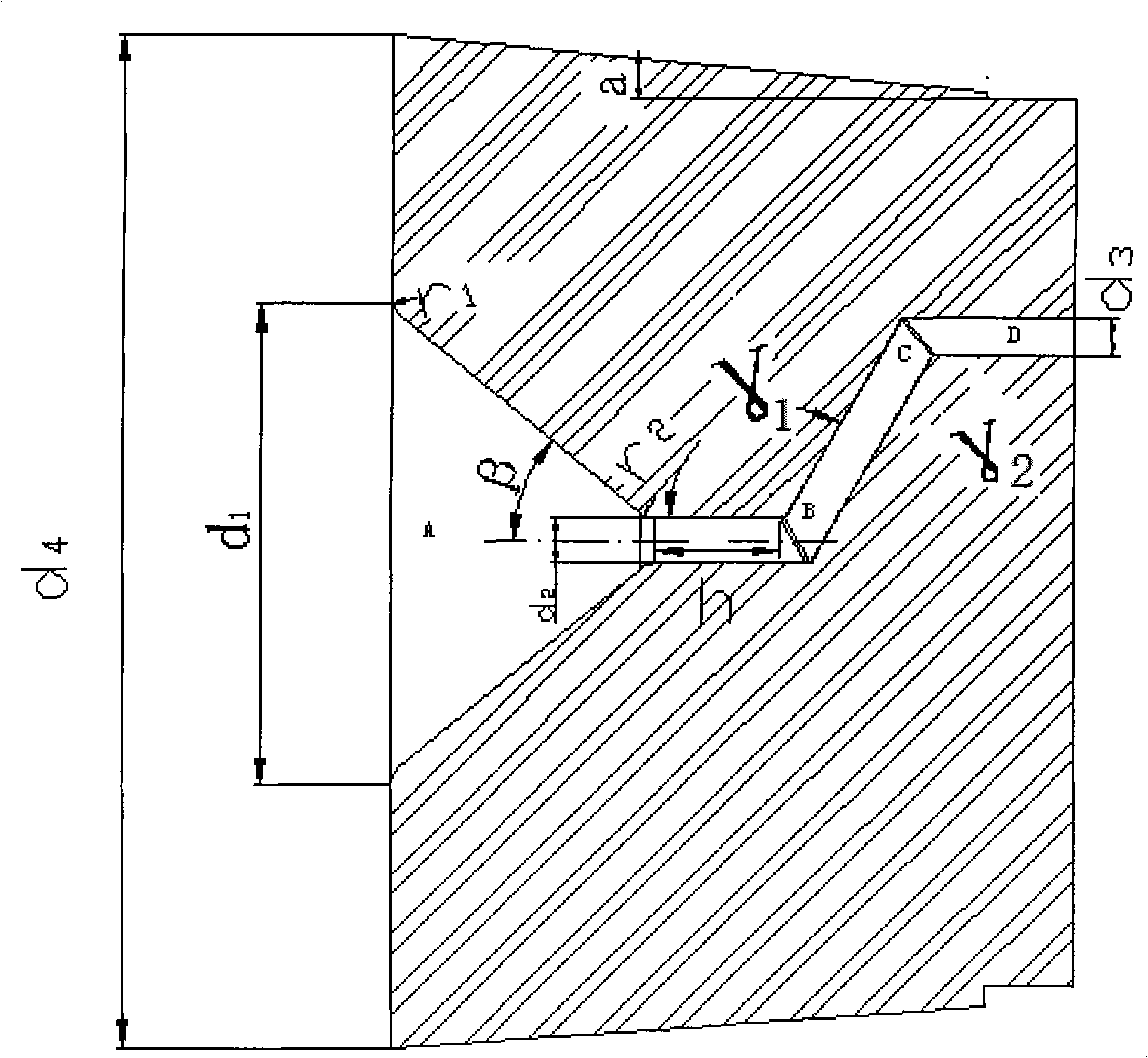

Embodiment 1

[0041] Set the extrusion ratio to 9, take a magnesium alloy billet of grade AZ31 with a diameter of Ф90mm, and homogenize the billet. The condition is to heat the billet to 400°C for 10 hours. At this time, the grain diameter of the billet is about 50 microns. Under the condition that the extrusion temperature is 300 degrees Celsius, the extrusion speed is 3 m / min, the extrusion cylinder and the die are heated to 275 degrees Celsius, and graphite is used as a lubricant, the magnesium alloy billet is extruded according to the above method. The length h of the working belt of the extrusion channel is 3mm; the two corners of the channel γ 1 , γ 2 Both are 90°, the diameter d of the bar in the extrusion stage 2 It is Ф40mm. The finished diameter d3 (finished product) of the extruded bar after shaping is Ф30mm. The microstructure observation of the extruded magnesium alloy shows that the grains are evenly distributed, fine and round equiaxed grains, with an average size of about ...

Embodiment 2

[0043] Set the extrusion ratio to 25, take a magnesium alloy casting slab with the brand name AZ31 and a diameter of Ф80mm, the state of the slab is extruded, and homogenize the slab. The condition is to heat the slab to 400°C for 12 hours. When the blank grain diameter is about 20 microns. The extrusion temperature is 300°C, the extrusion speed is 3m / min, the extrusion barrel and die are heated to 275°C, graphite is used as lubricant, and the magnesium alloy billet is extruded according to the above method, the length of the working zone of the extrusion channel is h 3mm; the two corners of the channel γ 1 , γ 2 Both are 120°, the diameter d of the bar in the extrusion stage 2 It is Ф20mm. Then carry out homogenization treatment at 400 degrees Celsius for 10 hours, and the finished diameter of the extruded rod after shaping is d 3 (Finished product) is Ф16mm. The microstructure observation of the magnesium alloy after extrusion reveals that the grains are uniformly distr...

Embodiment 3

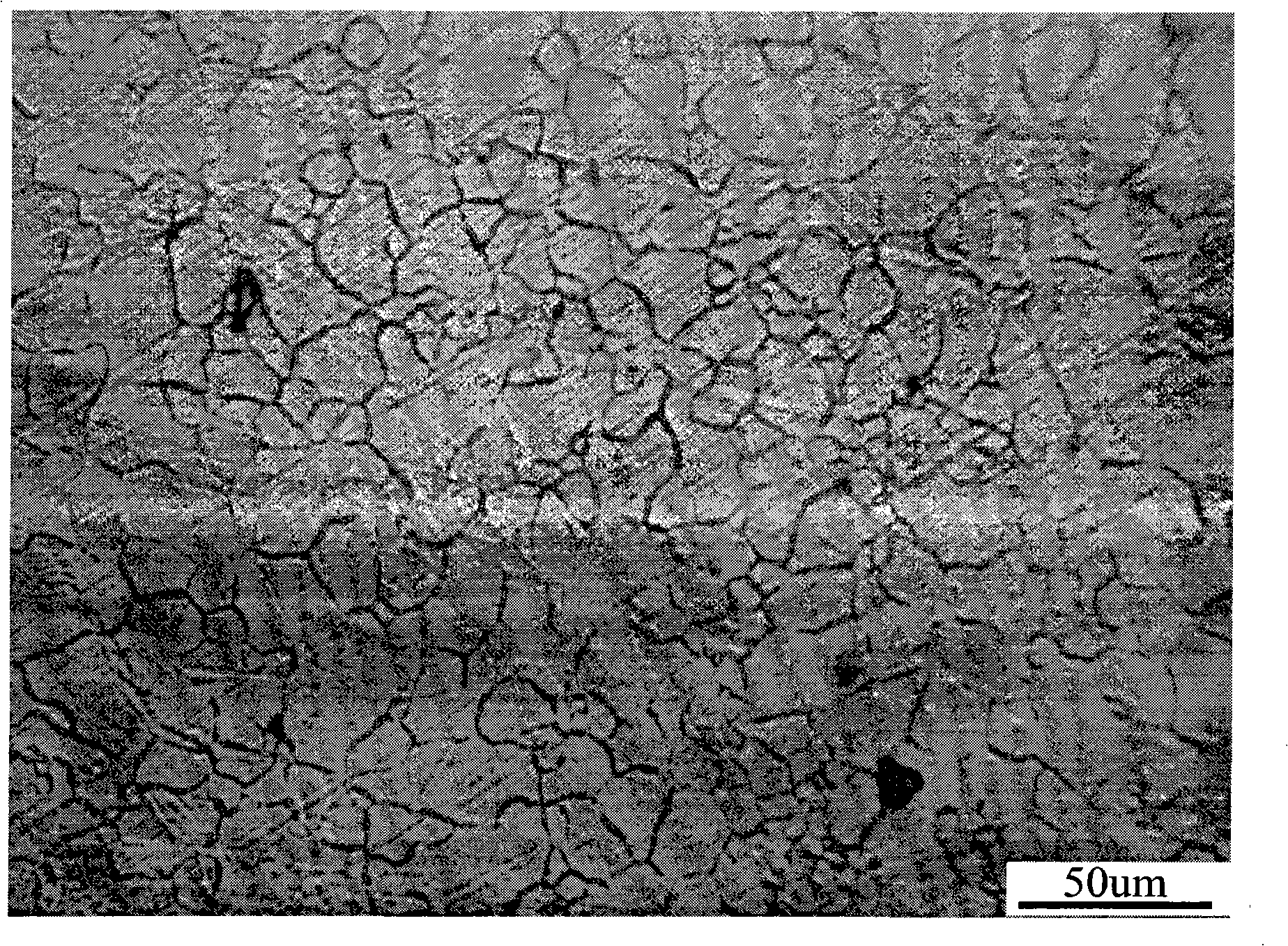

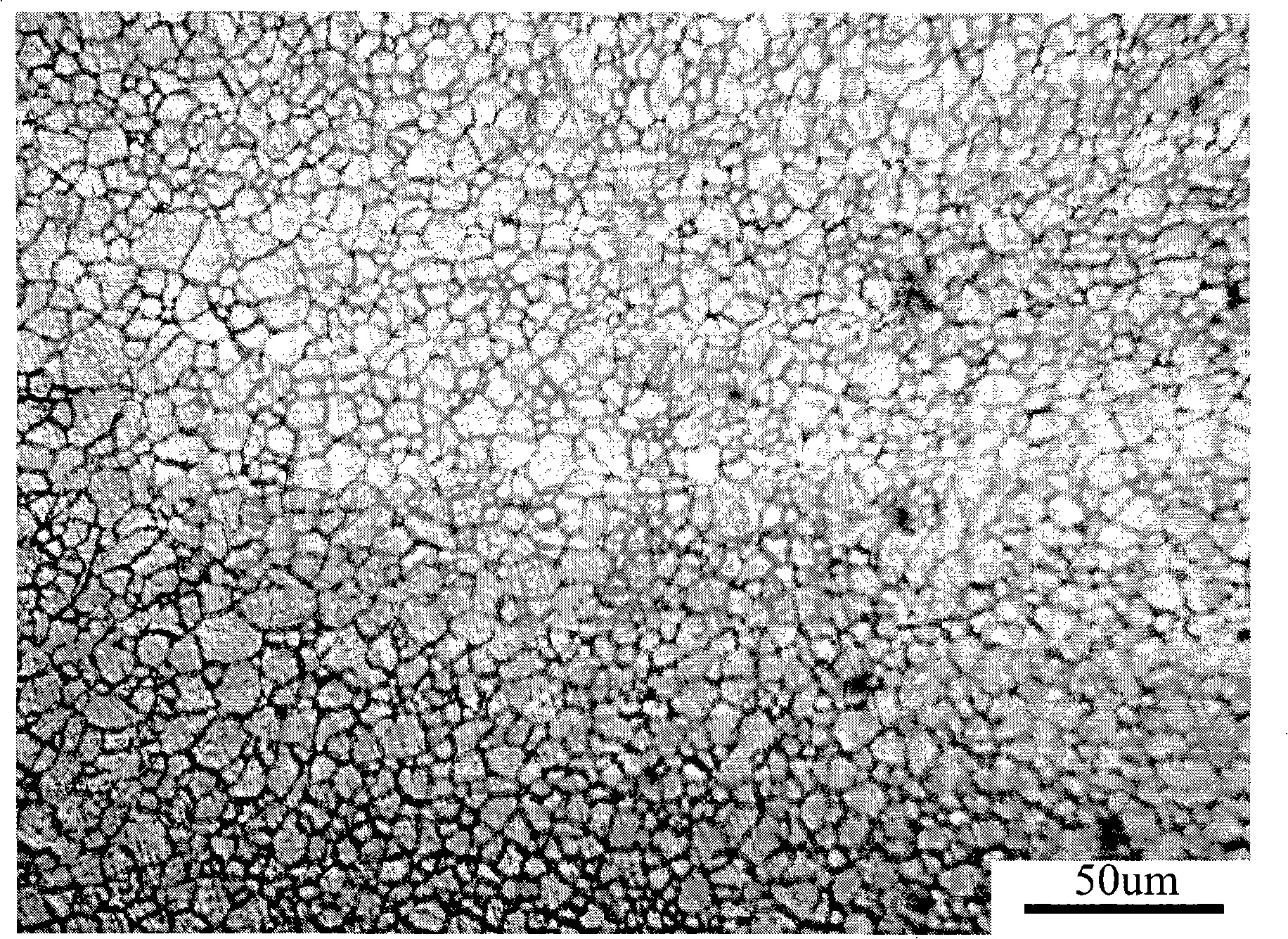

[0045] Set the extrusion ratio to 4, take a magnesium alloy billet of the brand AZ 31 and a diameter of Ф6mm, the state of the AZ31 billet is extruded, and homogenize the billet. The condition is to heat the billet to 380°C for 12 hours. At this time, the grain diameter of the billet is about 35 microns, see the attached figure 2 . The extrusion temperature is 325°C, the extrusion speed is 3m / min, the extrusion cylinder and the mold are heated to 300°C, graphite is used as a lubricant, and the magnesium alloy billet is extruded according to the above method. The length h of the working belt of the extrusion channel is 2mm; the two corners of the channel γ 1 , γ 2 Both are 90°, the diameter d2 of the bar in the extrusion stage is Ф6mm, and the finished diameter d3 (finished product) of the extruded bar after shaping is Ф3mm, see image 3 and Figure 4 . The microstructure observation of the magnesium alloy after extrusion reveals that the grains are uniformly distributed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com