Casting aluminum-silicon alloy and strengthening method thereof

A technology for casting aluminum-silicon alloys and aluminum-silicon intermediate alloys, which is applied in the strengthening of cast aluminum-silicon alloys, non-ferrous alloy materials and strengthening fields, can solve the problems that the potential strengthening effect of zinc cannot be fully exerted, and improve the plasticity and surface quality of materials And the effect of high dimensional accuracy and large application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

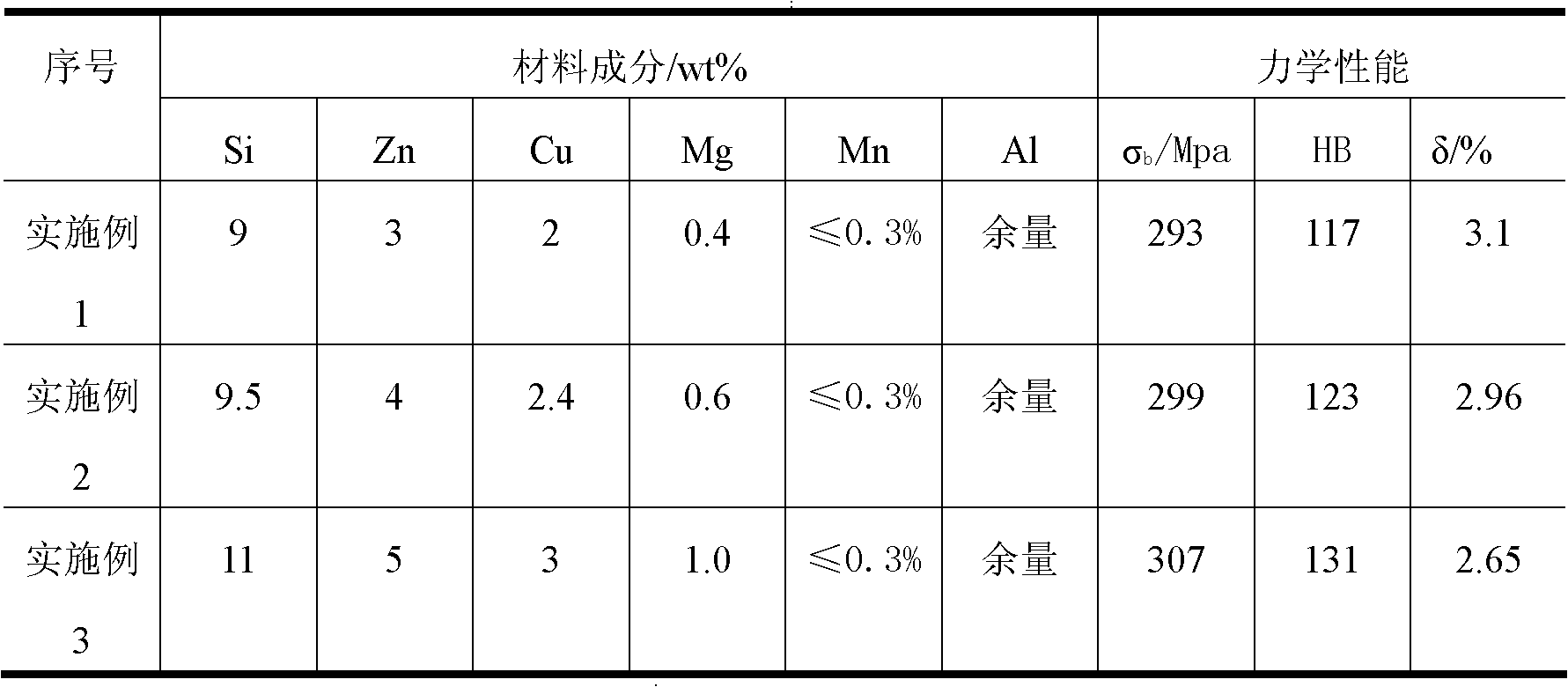

[0024] The following are three embodiments of the present invention, and the present invention is not limited to the following three embodiments.

[0025] The chemical composition of the cast aluminum-silicon alloy of the invention is calculated by weight percentage: 9.0-11.0% of silicon, 3.0-5.0% of zinc, 0.4-1.0% of magnesium, 2.0-3.0% of copper, manganese≤0.3%, and the rest is aluminum.

[0026] The strengthening method of cast aluminum-silicon alloy of the present invention comprises the following steps:

[0027] 1) Smelting

[0028] A. Loading

[0029] The order of charging is: aluminum-silicon master alloy, pure aluminum ingot, aluminum-copper master alloy, aluminum-manganese master alloy, zinc ingot, and the zinc ingot is added at 660°C after the furnace charge is melted;

[0030] B. Melting and refining

[0031] After the charge is loaded, heat up and melt. After the charge is completely melted, remove the slag and add flux; when the temperature reaches 680°C, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com