Surface strengthening treatment method for gradient pure copper material

A technology of surface strengthening and treatment method, applied in the field of metal material processing, can solve problems such as plasticity reduction, and achieve the effect of simple treatment method, easy continuous production, and less capital investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Anneal the 3mm pure copper plate at 600°C for 2.5 hours;

[0017] (2) Surface polishing the plate obtained in step (1). The polished pure copper plate is subjected to single-sided surface nano-treatment in a liquid nitrogen environment. The test frequency is 50 Hz, the steel balls are 100, the diameter is 8 mm, and the treatment time is 50 Hz. 15min.

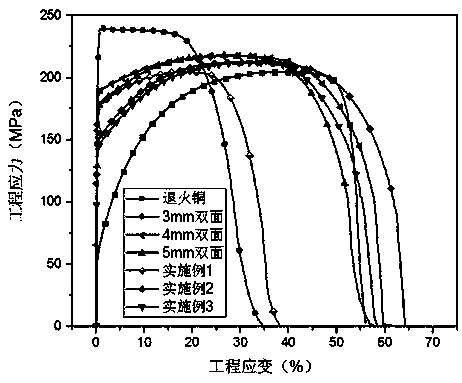

[0018] The yield strength of the prepared surface nanometer gradient pure copper material can reach 170Mpa (such as figure 1 As shown in the curve of Example 1), it is 3 times that of annealed pure copper, and the uniform elongation reaches 19%, and it is 9 times that of the graded pure copper material prepared by double-sided surface nanometering, and the elongation at break can reach 38% , Has high strength and good plasticity.

[0019] Gradient pure copper material (such as figure 1 The average elongation is 2%, and the elongation at break is 35%.

Embodiment 2

[0021] (1) Anneal 4mm pure copper sheet at 650℃ for 2 hours;

[0022] (2) Surface polishing the plate obtained in step (1). The polished pure copper plate is subjected to single-sided surface nano-treatment at room temperature. The test frequency is 50Hz, the steel balls are 150, the diameter is 8mm, and the treatment time is 15min. .

[0023] The yield strength of the prepared surface nanometer gradient pure copper material can reach 150Mpa (such as figure 1 As shown in the curve in Example 2), it is twice the annealed pure copper, and the uniform elongation reaches 35%. Compared with the gradient pure copper material prepared by double-sided surface nanometering, it has increased by 10%, and the fracture elongation can be Up to 65%, with high strength and good plasticity.

[0024] Gradient pure copper material (such as figure 1 As shown by the 4mm double-sided curve), the uniform elongation is 25%, and the elongation at break is 60%.

Embodiment 3

[0026] (1) Anneal the 5mm pure copper plate at 700℃ for 1.5 hours;

[0027] (2) Surface polishing the plate obtained in step (1). The polished pure copper plate is subjected to single-sided surface nano-treatment at room temperature. The test frequency is 50Hz, the steel balls are 200, the diameter is 8mm, and the treatment time is 15min. .

[0028] The yield strength of the prepared surface nanometer gradient pure copper material can reach 140Mpa (such as figure 1 As shown in the curve in Example 3), it is twice the annealed pure copper, and the uniform elongation reaches 40%. Compared with the gradient pure copper material prepared by double-sided surface nano-crystallization, the elongation at break can be increased by 10%. Up to 60%, with high strength and good plasticity.

[0029] Gradient pure copper material (such as figure 1 The average elongation rate is 30%, and the elongation rate at break is 57%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com