Difficultly-deformed nickel-based superalloy superplastic forming method

A high-temperature alloy and superplastic technology, applied in the field of forging, can solve problems such as low efficiency and complex process of hard-to-deform high-temperature alloy forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

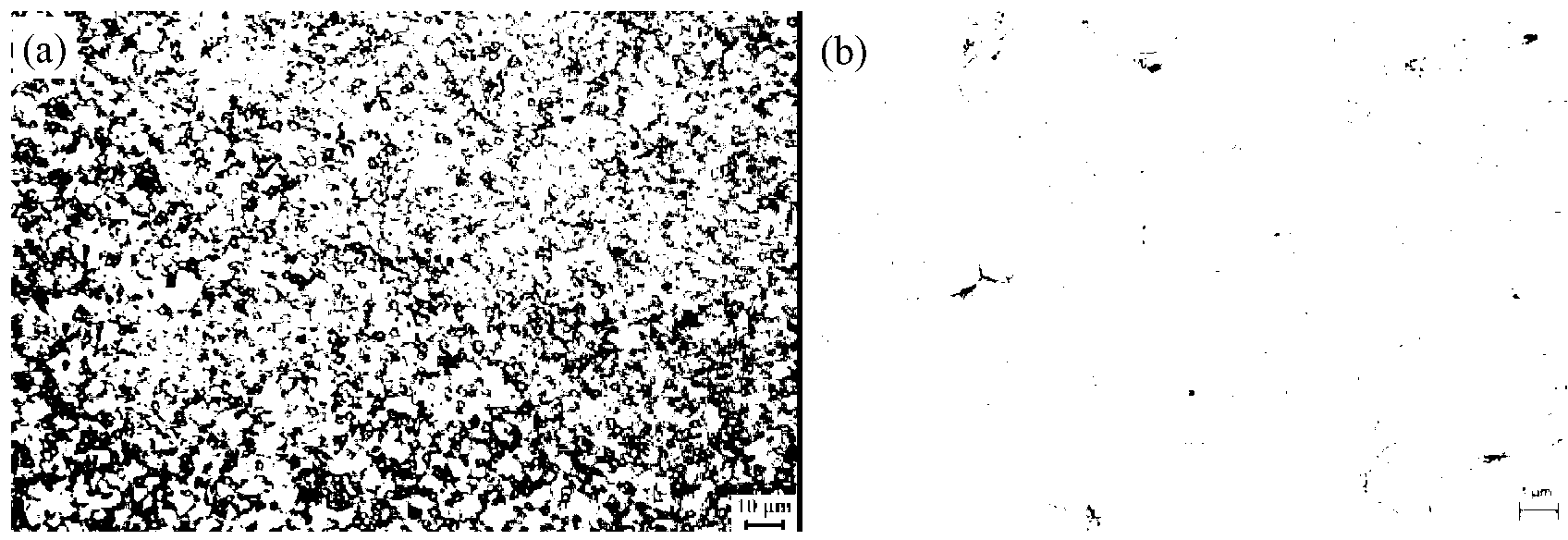

[0025] Embodiment 1: Taking forging a Φ180mm cake blank as an example, this embodiment proposes a process for realizing superplastic forming of a difficult-to-deform superalloy, which is characterized in that it specifically includes the following steps:

[0026] step 1:

[0027]1) Preparation of forging billet, the billet is a deformed nickel-based superalloy strengthened by γ¢ phase or related to it. In this preferred embodiment, the GH4720Li alloy is used to hard coat the regular Φ100mm×240mm cylindrical rod blank. The initial grain size is 8μm, and the main chemical composition is C: 0.01; Al: 2.35; Ti: 4.95; Co: 15.0; Cr: 16.0; Mo: 3.05; W: 1.2; Fe: 0.2; B: 0.015; Zr: 0.035; S: 0.001; P: 0.01; Ni balance;

[0028] 2) Select hydraulic press equipment and forging dies, and select die materials (superalloy C: 0.01, Cr: 16.1, Al: 6.2, Mo: 9.1, W: 6.2, Ta: 3.1, Hf: 3.2, Ti: 2.9, B: 0.15, S: 0.001, Ni balance) can be stronger than this nickel-based superalloy under 1150 ℃ and...

Embodiment 2

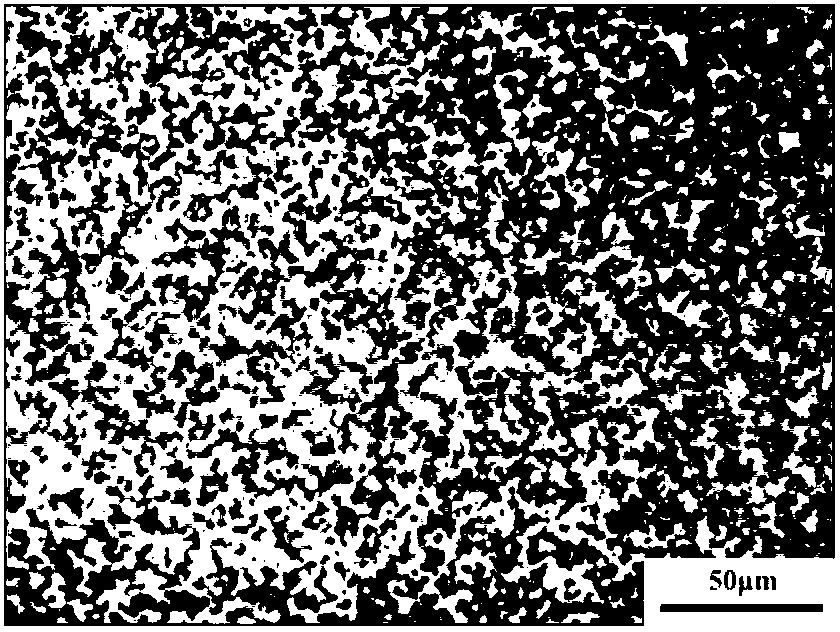

[0033] Embodiment 2: Taking forging a Φ180mm cake blank as an example, this embodiment proposes a process for realizing superplastic forming of a difficult-to-deform superalloy, which is characterized in that it specifically includes the following steps:

[0034] step 1:

[0035] 6) Preparation of forging billet. The billet is a deformed nickel-based superalloy strengthened by γ¢ phase or related to it. In this preferred embodiment, the GH4720Li alloy is used to hard coat the regular Φ100mm×240mm cylindrical rod blank. The initial grain size is 8μm, and the main chemical composition is C: 0.0125; Al: 2.25; Ti: 5.25; Co: 15.5; Cr: 16.5; Mo: 2.75; W: 1.5; Fe: 0.2; B: 0.015; Zr: 0.035; S: 0.001; P: 0.01; Ni balance;

[0036] 7) Select hydraulic press equipment and forging dies, and select die materials (superalloy C: 0.01, Cr: 16.1, Al: 6.2, Mo: 9.1, W: 6.2, Ta: 3.1, Hf: 3.2, Ti: 2.9, B: 0.15, S: 0.001, Ni balance) can be stronger than this nickel-based superalloy under 1150 ℃ ...

Embodiment 3

[0041] Embodiment 3: Taking forging a Φ180mm cake blank as an example, this embodiment proposes a process for realizing superplastic forming of a difficult-to-deform superalloy, which is characterized in that it specifically includes the following steps:

[0042] step 1:

[0043] 11) Preparation of forging billet, the billet is a deformed nickel-based superalloy strengthened by γ¢ phase or related. In this preferred embodiment, the GH4720Li alloy is used to hard coat the regular Φ100mm×240mm cylindrical rod blank. The initial grain size is 8μm, and the main chemical composition is C: 0.015; Al: 2.75; Ti: 4.75; Co: 14.0; Cr: 15.5; Mo: 3.25; W: 1; Fe: 0.2; B: 0.015; Zr: 0.035; S: 0.001; P: 0.01;

[0044] 12) Select hydraulic press equipment and forging dies, and select die materials (superalloy C: 0.01, Cr: 16.1, Al: 6.2, Mo: 9.1, W: 6.2, Ta: 3.1, Hf: 3.2, Ti: 2.9, B: 0.15, S: 0.001, Ni balance) can be stronger than this nickel-based superalloy under 1150 ℃ and forging deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com