Method for producing homogeneous fine grain titanium materials suitable for ultrasonic inspection

a technology of titanium material and ultrasonic inspection, which is applied in the field of titanium material production methods, can solve the problems of limiting the application of titanium, unsatisfactory noise, and defects in titanium materials, and achieves the effect of reducing the number of defects and improving the quality of titanium materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

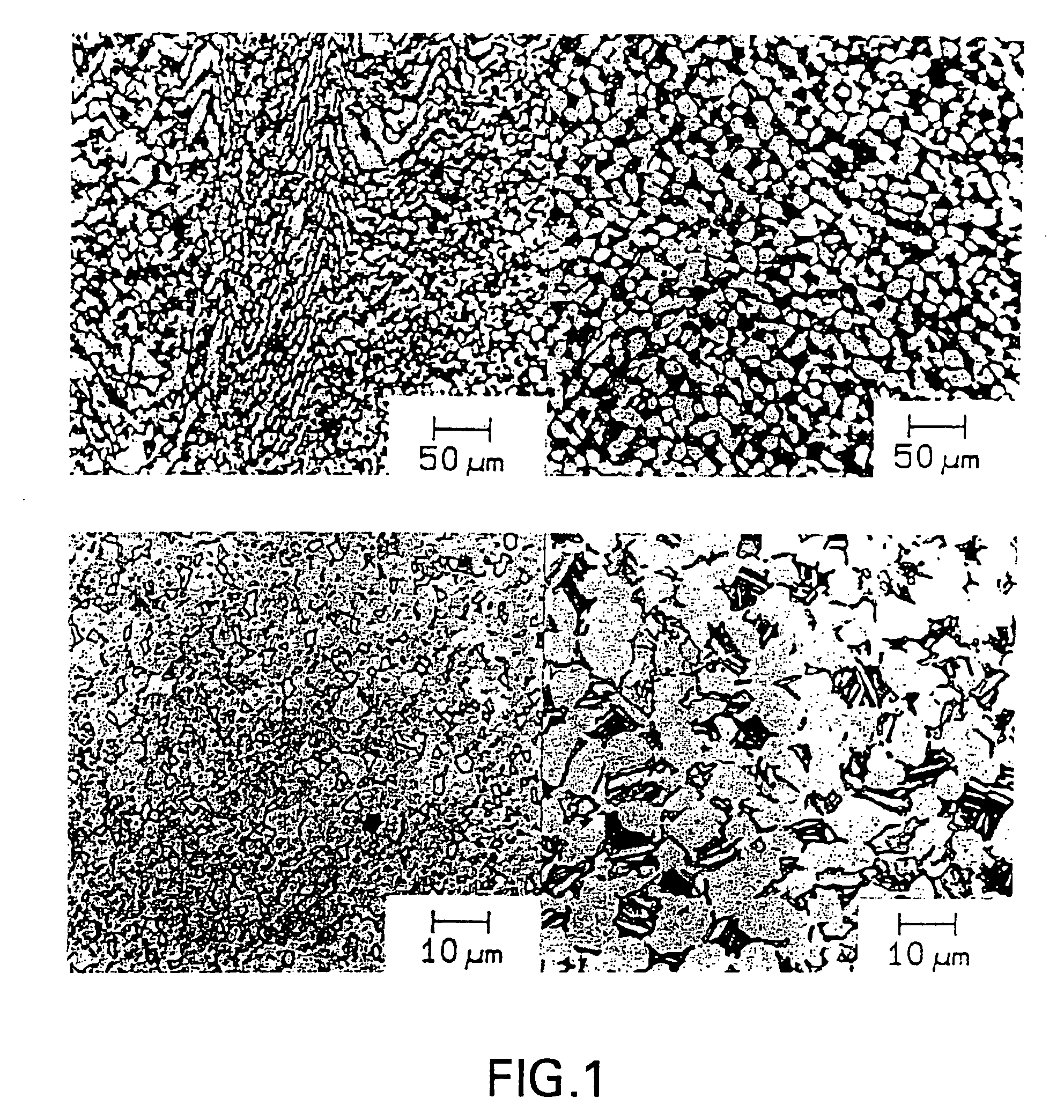

[0036] Titanium material blanks comprising a two-phase titanium alloy (Ti-6242) having a Tpt of about 1000° C were provided. The titanium material blanks were cut from a deformed β-region in a titanium material rod. The dimensions of the titanium material blanks were 100 mm by 100 mm by 200 mm. The β-grain size was in from about 3 mm to about 5 mm. The titanium material microstructure was extended or elongated in a direction of deformation.

[0037] The titanium material blanks were initially heated to a temperature in the β-region (T equal to about 1020° C., dwelling time equal to about 1 hour). The titanium material blanks were then quenched from the temperature of the β-region to create a homogeneous fine grain microstructure in (α+β)-region. Disperse lamellar microstructure was formed and a layer of α-phase titanium was formed disposed around boundaries of the β-grains with a reduced thickness compared to conventional titanium material production methods. This titanium material pr...

example 2

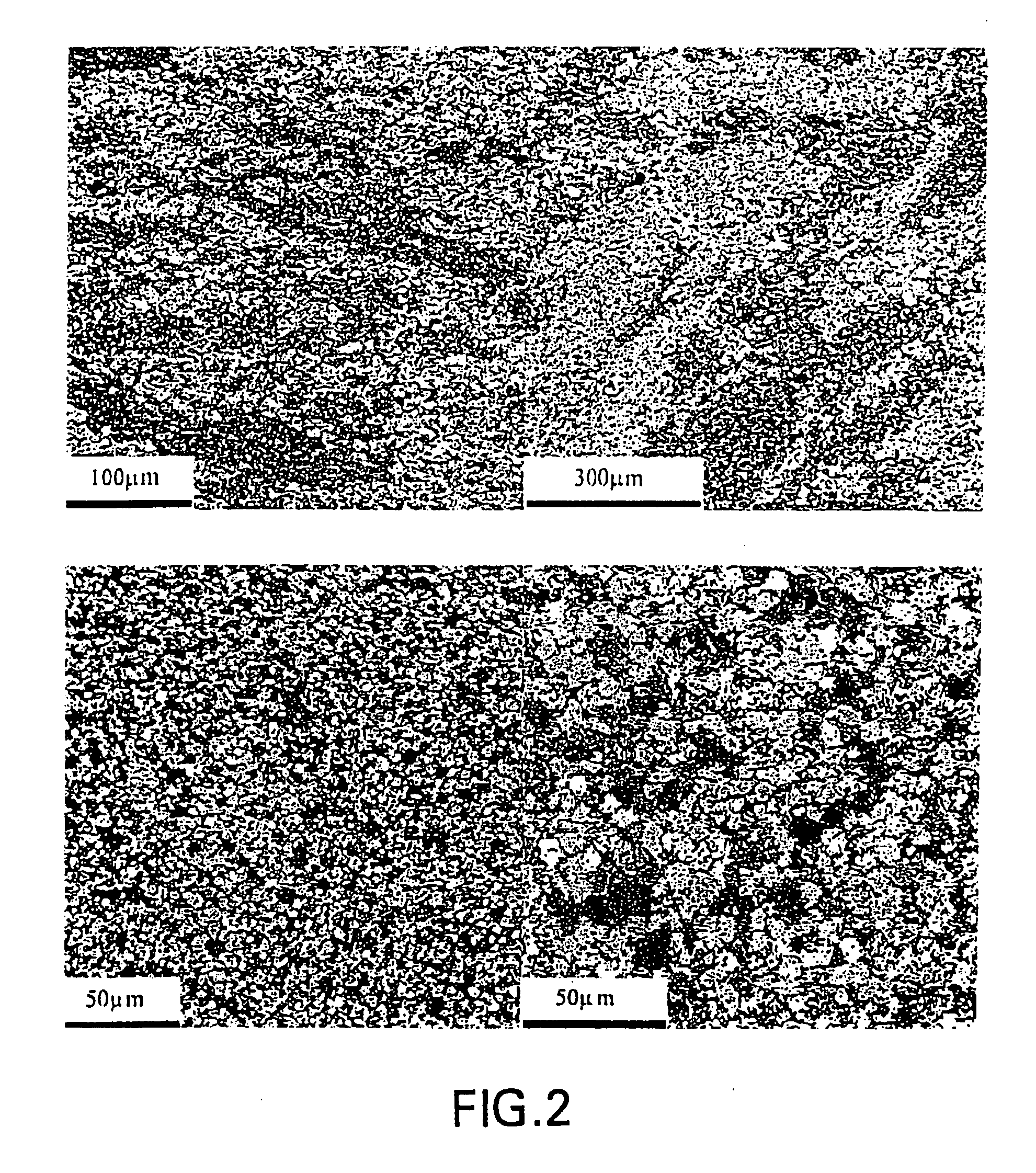

[0039] Titanium material blanks comprising a two-phase titanium alloy (IMI550) were provided. The alloy had a Tpt of about 965° C. for an ingot and a Tpt of about 980° C. for a forging. The titanium material formed as an ingot (billet) with an approximate size of 634 mm by 540 mm was prepared by a titanium material production method that included subjecting the titanium material to a forging in the β-region. This step was followed by heat treatment at about 1200° C., and thereafter by forging and rollforming. This step included settling, forging on the square, and rollforming. A heat treatment step followed with heating at 1140° C. and forging to 390 mm. These steps were followed by cooling in air. Further, the titanium material production method, as embodied by the invention, included a step of heating at Tpt−30° C. and forging to 310 mm, heating at 1060° C., forging to 280 mm, and cooling by air were conducted. Further, the titanium material blank was subjected to heating at Tpt−3...

example 3

[0042] Titanium material blanks comprising a two-phase titanium alloy (VT8-1) were provided, in which the titanium material blanks possessed a Tpt of about 965° C. as an ingot and a Tpt of about 1000° C. as a forging. The ingot, which has a size of about 628 mm by 535 mm, was subjected to a forging in the β-region of titanium. The forging was followed by heat treatment at about 1200° C., and forging that included rollforming, settling, forging on a square, and rollforming. This step was followed by heat treatment at about 1140° C., forging to about 390 mm, and a cooling by air. Further, a heat treatment at about Tpt−30° C. and forging to 310 mm, heating at about 1060° C. and forging to 280 mm followed by cooling in air were also conducted on the titanium material blanks.

[0043] The titanium material blank can then be subjected to heating at about Tpt−30° C. followed by forging. The forging included settling, forging on a square, roll-forming, and forging to 245 mm. After a heat trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com