Antigravity squeeze casting device of aluminum alloy connecting rod and manufacture method

A technology of extrusion casting and manufacturing method, which is applied in the field of anti-gravity extrusion casting method and mold device of aluminum alloy connecting rod, can solve the problems of large investment in machine tool equipment, consumption of tools and energy, and low utilization rate of materials, so as to avoid Effects of gas and slag entrapment, smooth exhaust, dimensional accuracy and improved surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

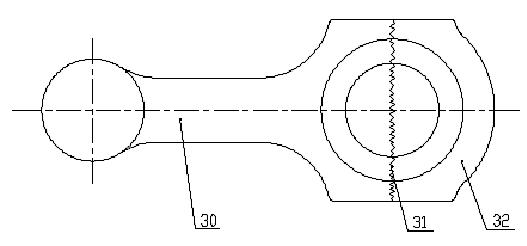

[0033] figure 1 It is a schematic diagram of the connecting rod in this embodiment, which includes a connecting rod body 30 and a connecting rod cover 32 , and the interlocking structure of the cracking interface 32 ensures precise meshing between the two.

[0034] In this embodiment, the anti-gravity squeeze casting method is used to manufacture cracked aluminum alloy connecting rods. The material of the connecting rod is LD10 aluminum alloy, and the foil material used for cracking the connecting rod is magnesium-based alloy AZ31 with a thickness of 0.1mm.

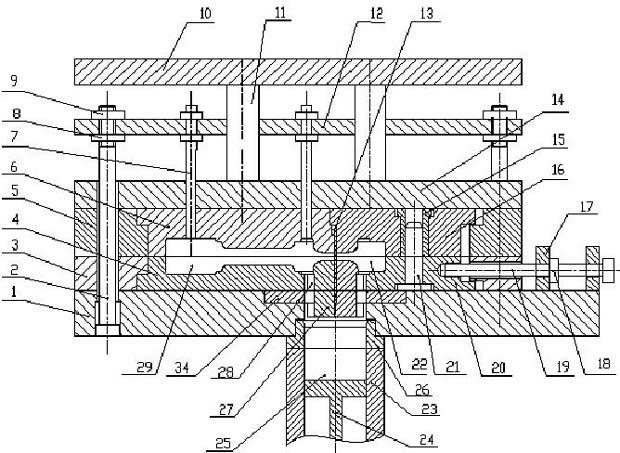

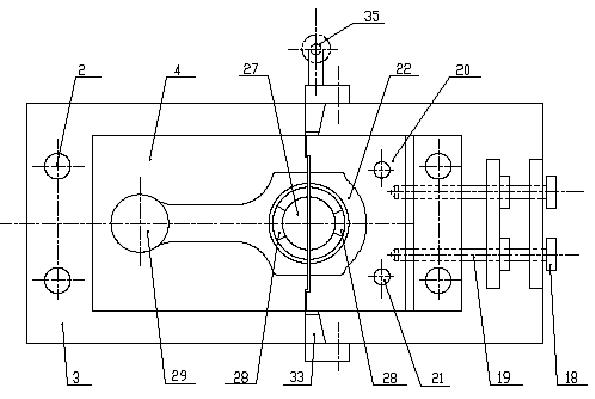

[0035] combine figure 1 , figure 2 , the anti-gravity extrusion casting device of aluminum alloy connecting rod among the present invention, comprises upper mold two 16, upper mold one 6, lower mold one 4, lower mold two 20, upper mold frame 5, lower mold frame 3, diverter cone 27. Snap ring 34, sprue sleeve 26, liquid material cylinder 23, pressure head 24, screw mandrel 19, pull rod 2, ejector rod 7, upper mold pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com