Preparation method of semisolid slurry of rare earth magnesium alloy

A technology of semi-solid slurry and rare earth magnesium, which is applied in the field of semi-solid forming of metal materials to achieve the effect of improving efficiency and cost, shortening semi-solid processing process and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

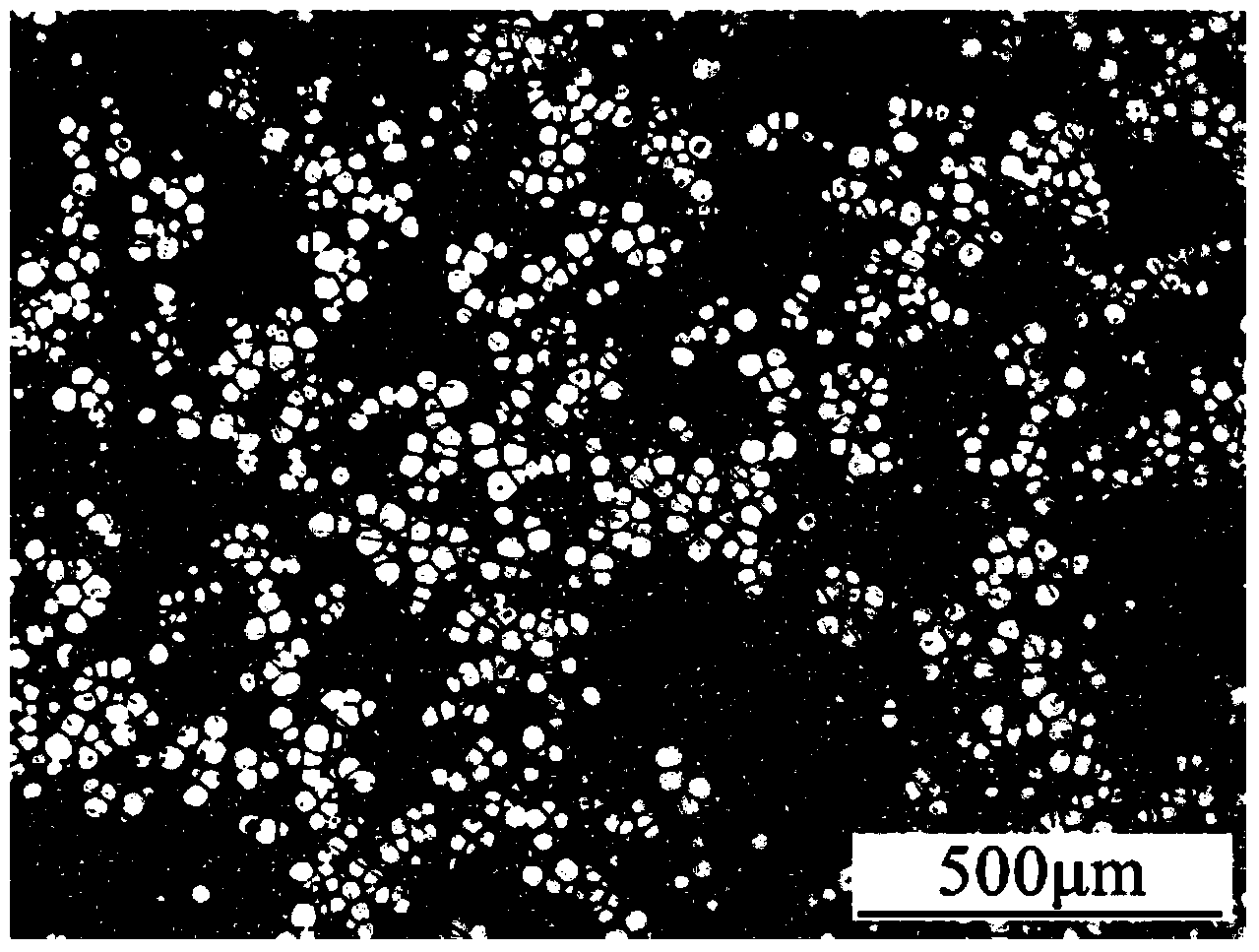

Embodiment 1

[0054] This embodiment relates to a kind of rare earth magnesium alloy Mg-11wt.%Y-4wt.Gd%. The melting and refining process is as follows: all the tools in contact with the alloy melt are painted in advance, and the tools, charge, refining agent and sampling copper mold are all in the Dry at 180°C for more than 3 hours. Turn on the resistance furnace, preheat the stainless steel crucible to dark red, add magnesium ingots, and start feeding CO2+SF6 protective gas with a volume ratio of 100:1 at 300°C until the casting work is completed. Raise the temperature of the crucible resistance furnace to 700°C until the pure magnesium is completely melted, and then adjust the temperature to 720°C-750°C. The magnesium in the alloy smelting base material with this composition is pure magnesium with a purity of 99%, gadolinium and yttrium are respectively added in the form of a Mg-90wt.% Gd master alloy and a Mg-25wt.% Y master alloy. After each master alloy is melted, the alloy melt is s...

Embodiment 2

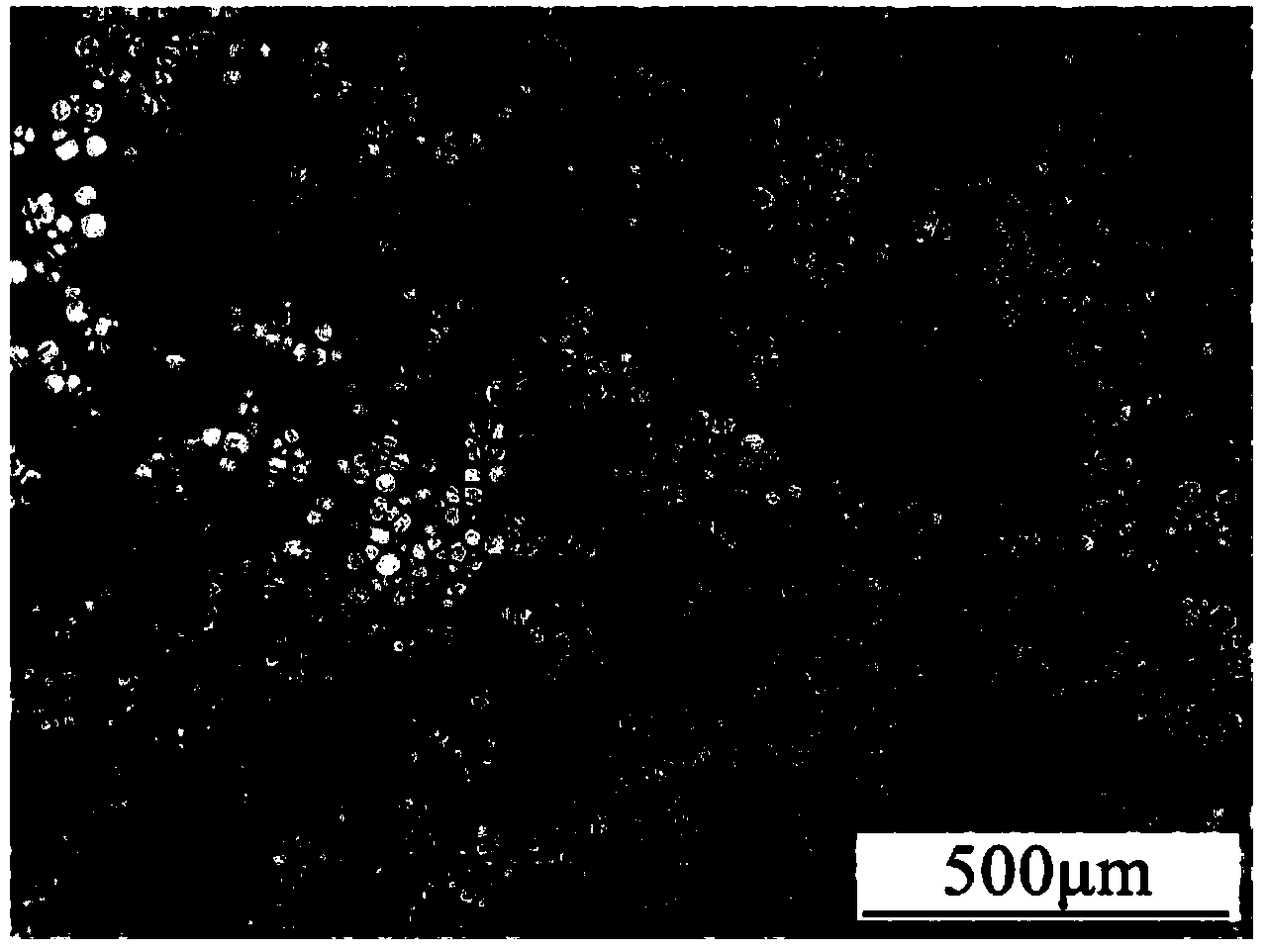

[0059] This embodiment relates to a rare earth magnesium alloy Mg-10wt.%Gd-3wt.%Y. The melting and refining process is as follows: all tools in contact with the alloy melt are painted in advance, and the tools, charge, refining agent, and sampling copper mold are all in the Dry at 180°C for more than 3 hours. Turn on the resistance furnace, preheat the stainless steel crucible to dark red, add magnesium ingots, and start feeding CO with a volume ratio of 100:1 at 300°C 2 +SF 6 Shielding gas until the casting work is completed. Raise the temperature of the crucible resistance furnace to 700°C until the pure magnesium is completely melted, and then adjust the temperature to 720°C-750°C. The magnesium in the alloy smelting base material with this composition is pure magnesium with a purity of 99%, gadolinium and yttrium are respectively added in the form of a Mg-90wt.% Gd master alloy and a Mg-25wt.% Y master alloy. After each master alloy is melted, the alloy melt is stirred ...

Embodiment 3

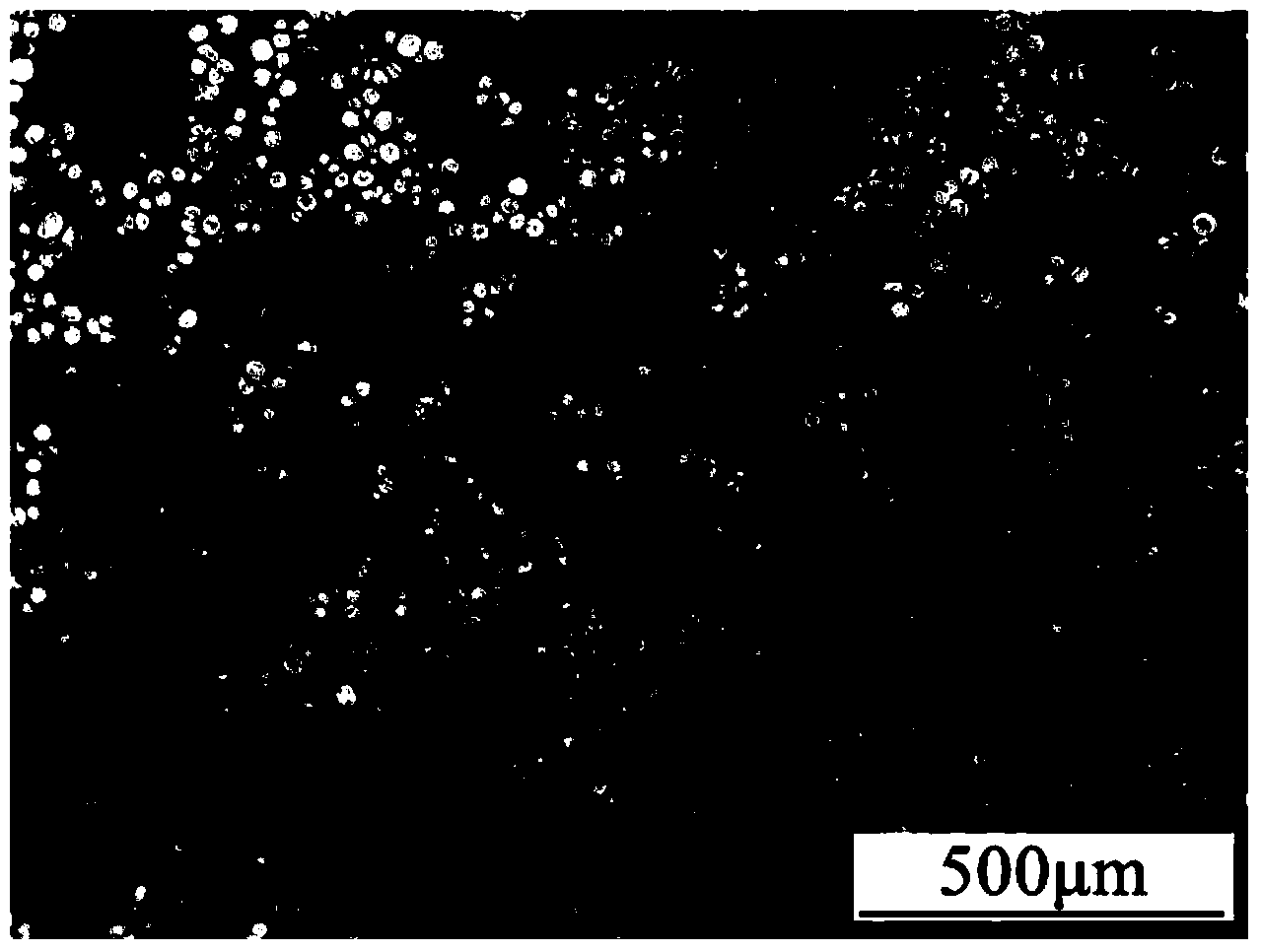

[0064] This embodiment relates to a rare earth magnesium alloy Mg-10wt.%Gd-0.5wt.%Ca. The melting and refining process is as follows: all tools in contact with the alloy melt are painted in advance, and the tools, charge, refining agent, and sampling copper mold are all Dry at 180°C for more than 3 hours. Turn on the resistance furnace, preheat the stainless steel crucible to dark red, add magnesium ingots, and start feeding CO with a volume ratio of 100:1 at 300°C 2 +SF 6 Shielding gas until the casting work is completed. Raise the temperature of the crucible resistance furnace to 700°C until the pure magnesium is completely melted, and then adjust the temperature to 720°C-750°C. The magnesium used in the alloy smelting base metal of this composition is pure magnesium with a purity of 99%, gadolinium is added in the form of Mg-90wt.%Gd master alloy, and calcium is added with 99.9% pure calcium (use filter paper to absorb the surface before adding pure calcium. Kerosene, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com