Preparation method of semisolid alloy slurry and rheoforging device

A molding equipment, semi-solid technology, applied in the direction of metal processing equipment, casting equipment, manufacturing tools, etc., can solve the problems of complex composition, troublesome preparation process, no special settings, etc., to achieve simple equipment structure, reduce equipment investment, and reduce production costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

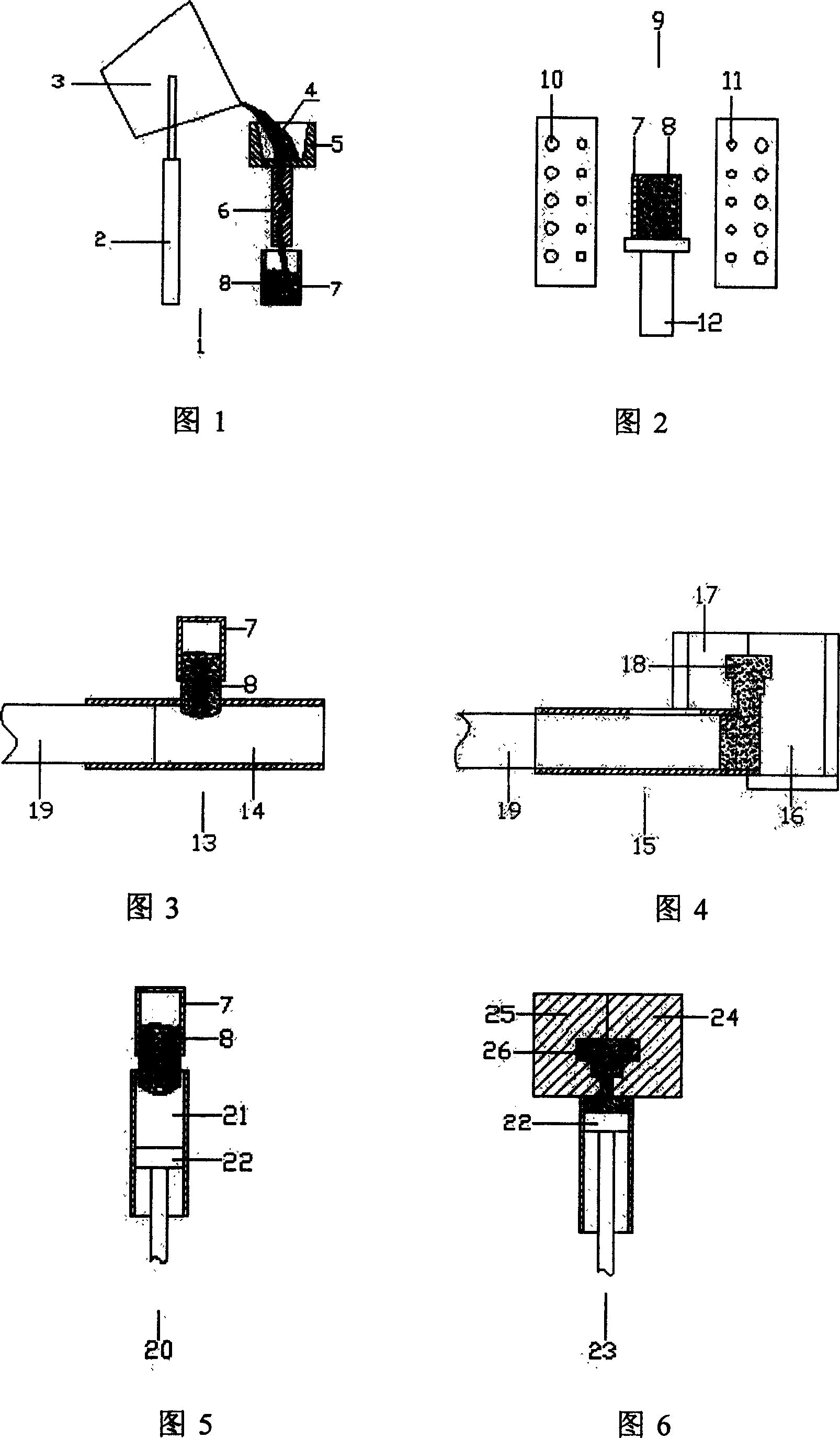

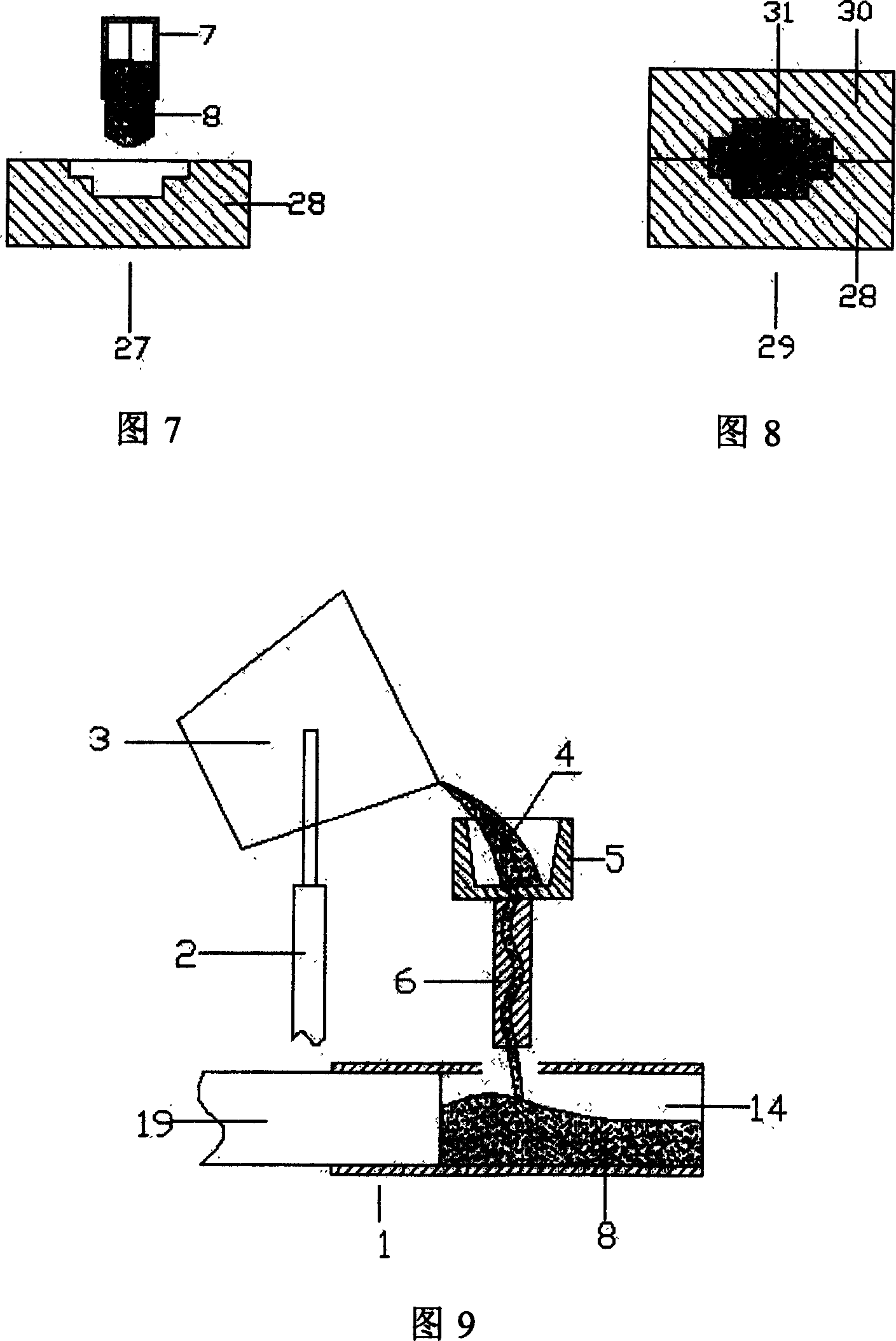

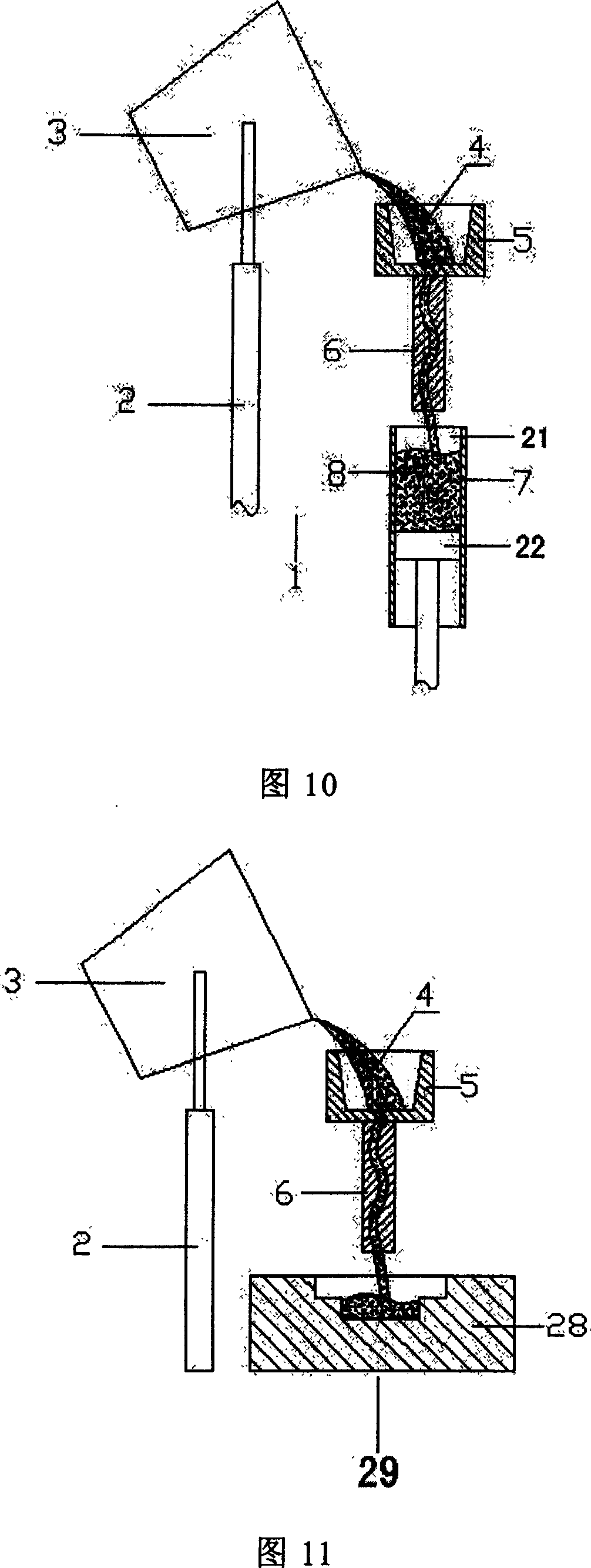

[0038]With reference to Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 13, this is the technological process and device provided by the above-mentioned technical characteristics. The process is provided with a lifting mechanism 2, which is driven by a hydraulic system; the overheated ZL101A aluminum alloy (i.e. hypoeutectic Al-7wt%Si-0.45wt%Mg aluminum alloy) liquid melting furnace 3 is a resistance melting furnace, and the resistance The heat preservation performance of the melting furnace is good, which can ensure the temperature control accuracy of the ZL101A aluminum alloy liquid 4, and the temperature control accuracy is ±10°C; the overheated ZL101A aluminum alloy liquid melting furnace 3 is connected with the sprue cup 5, and the sprue cup is made of graphite ; The sprue cup 5 is connected with the vertical serpentine runner 6, the height of the serpentine runner 6 is 300mm, the inner diameter is 15mm, and the inner arc bend of the serpentine runner 6 is 3, the serpentine runner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com