Foaming silican carbide ceramic strengthening copper base composite abrasive sheet and preparation process thereof

A technology of copper-based composite materials and foamed silicon carbide, applied in the direction of friction linings, mechanical equipment, etc., can solve the problem of inability to effectively suppress the high-temperature deformation and adhesive wear of friction linings, the limitation of the improvement range of heat resistance of friction linings, and the heat resistance of friction linings. The problems such as the improvement limit of the machine can be solved, and the effects of considerable economic and social benefits, low wear rate and reduced wheel pressure can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

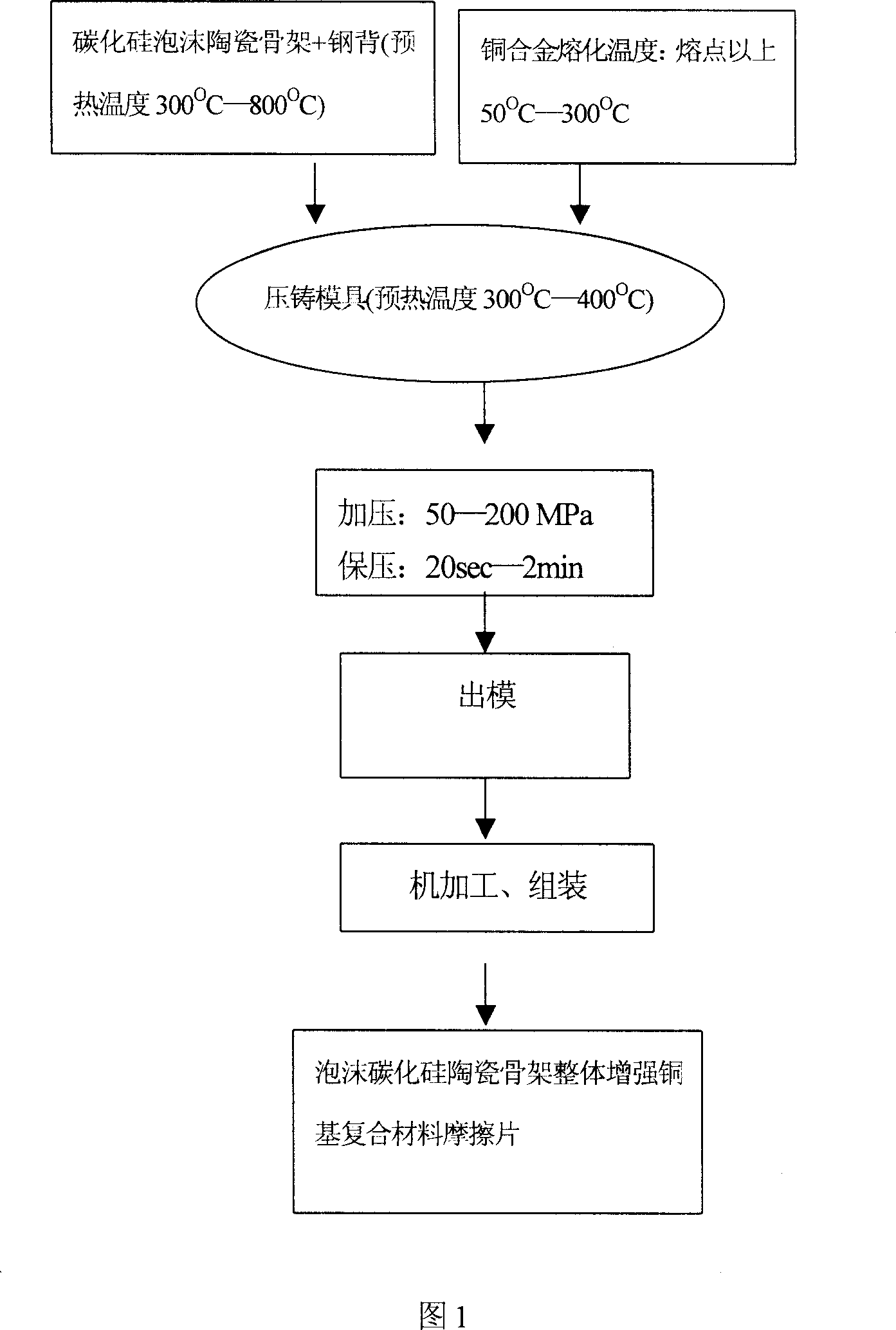

Method used

Image

Examples

Embodiment 1

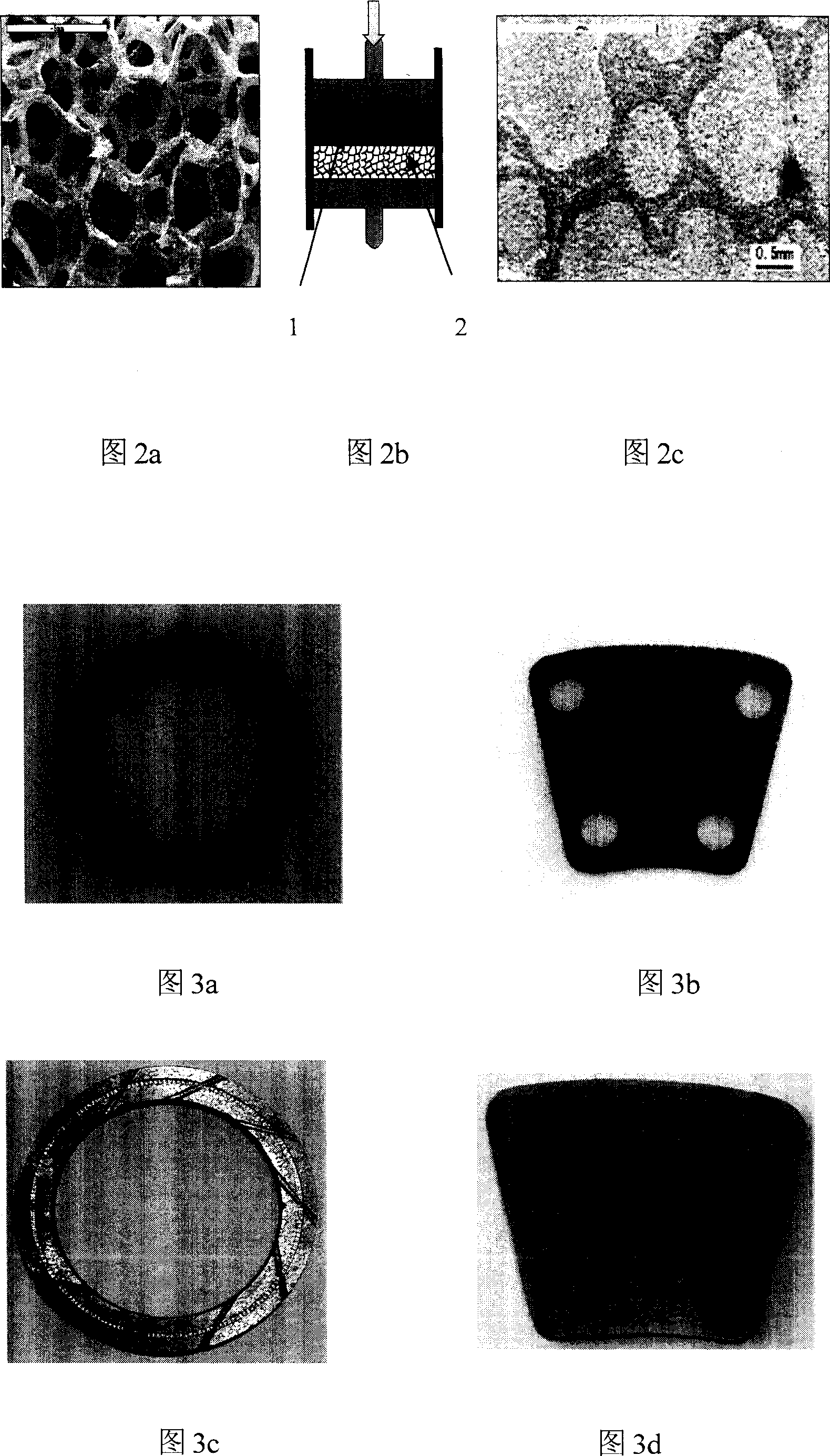

[0052] First prepare foamed silicon carbide ceramics according to the method provided by the patent application number 03134039.3. The skeleton of the foamed silicon carbide ceramics is shown in Figure 3a. The size of the foamed silicon carbide ceramics is: a ring with an outer diameter of Φ85mm, an inner diameter of Φ75mm, and a thickness of 3mm. On a 45# steel ring with a diameter of Φ97mm, an inner diameter of Φ75mm, and a thickness of 10mm, heat it to 300°C and put it into a mold of Φ100mm.

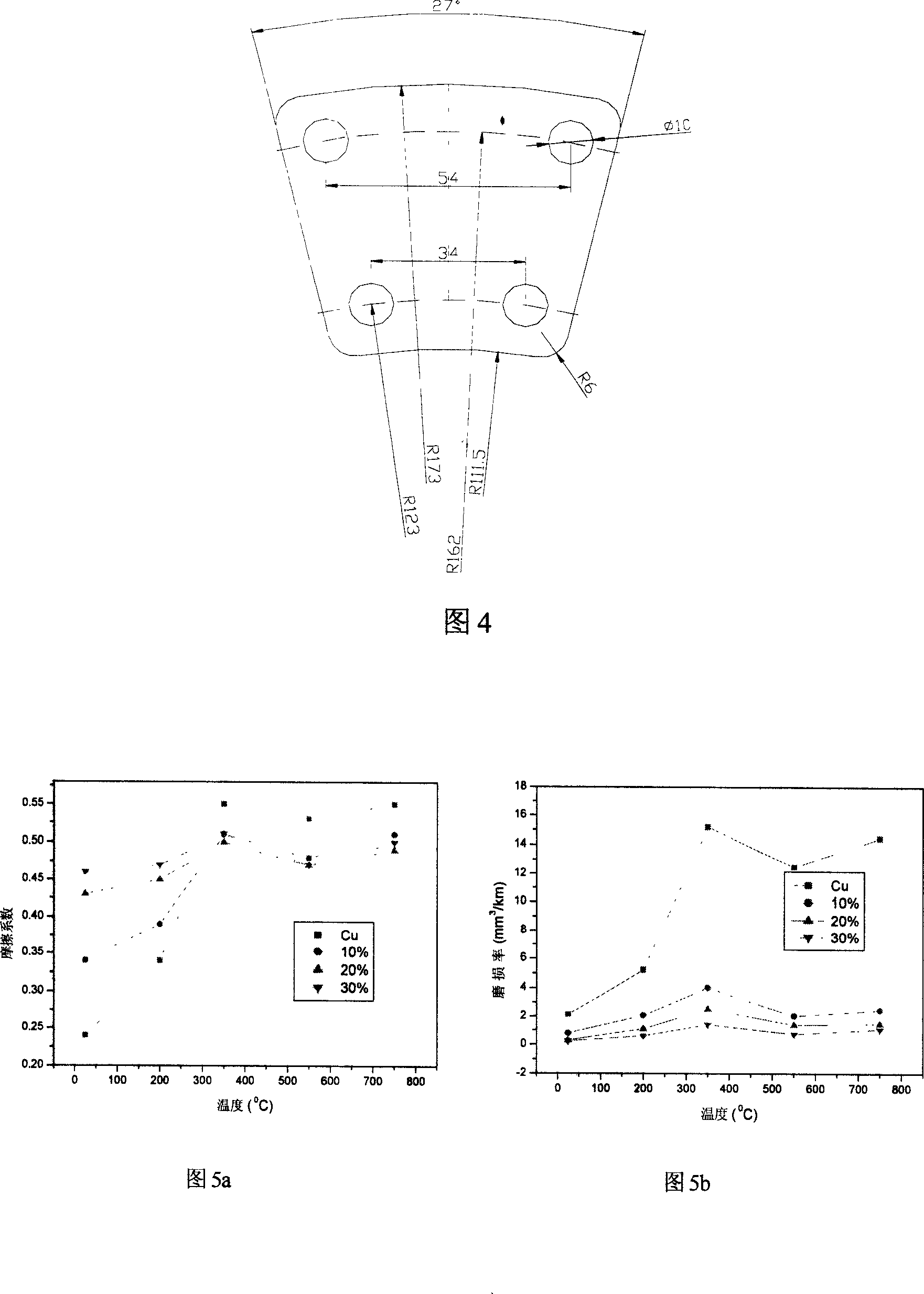

[0053] Using the die-casting method, heat the iron brass Hfe59-1-1 to the melting point temperature (901°C) above 100°C, press it into the foamed silicon carbide ceramic skeleton with a pressure of 50MPa, and hold the pressure for 20 seconds. Size, you can get foam silicon carbide ceramic skeleton integrally reinforced copper matrix composite friction plate (see Figure 3c). The friction plate has the characteristics of good heat resistance, excellent friction performance, high mechan...

Embodiment 2

[0055] The difference from Example 1 is:

[0056] First prepare foamed silicon carbide ceramics according to the method provided by the patent application number 03134039.3. Among them, the size of the foamed silicon carbide ceramics is: a ring with an outer diameter of Φ90, an inner diameter of Φ75, and a thickness of 3mm. The mesh size is 0.2mm, and the volume fraction is 20%. 10mm 65 manganese steel ring, heated to 500°C and placed in a Φ100 mold.

[0057] Using the die-casting method, the silicon brass Hsi80-3 is heated to a melting point temperature (900°C) of 150°C or higher, the pressure is 80MPa, the holding time is 30 seconds, pressed into the foamed silicon carbide ceramic skeleton, and machined to the required size. The foamed silicon carbide ceramic framework integrally reinforced copper-based composite material friction plate can be obtained. The friction plate has the characteristics of good heat resistance, excellent friction performance, high mechanical stren...

Embodiment 3

[0059] The difference from Example 1 is:

[0060] First prepare foamed silicon carbide ceramics according to the method provided by the patent application number 03134039.3. Among them, the size of the foamed silicon carbide ceramics is: a ring with an outer diameter of Φ200, an inner diameter of Φ160, and a thickness of 3mm. The mesh size is 1mm, and the volume fraction is 30%. On the stainless steel ring, heat it to 800°C and put it into a Φ220 mold.

[0061] Using the die-casting method, heat the tin bronze QSn6-6-3 to the melting point temperature (1019°C) above 200°C, use a pressure of 100MPa, hold the pressure for 40 seconds, press it into the foamed silicon carbide ceramic skeleton, and machine it to the required size , you can get foam silicon carbide ceramic skeleton overall reinforced copper matrix composite material friction plate. The friction plate has the characteristics of good heat resistance, excellent friction performance, high mechanical strength and good ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com