Self-repairing and oil stain-preventing coating and preparation method thereof, and protective film containing same and preparation method thereof

An anti-fouling and self-healing technology, used in anti-fouling/underwater coatings, coatings, anti-corrosion coatings, etc. Repair and other problems, to achieve excellent self-healing function, better protection effect, and avoid adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

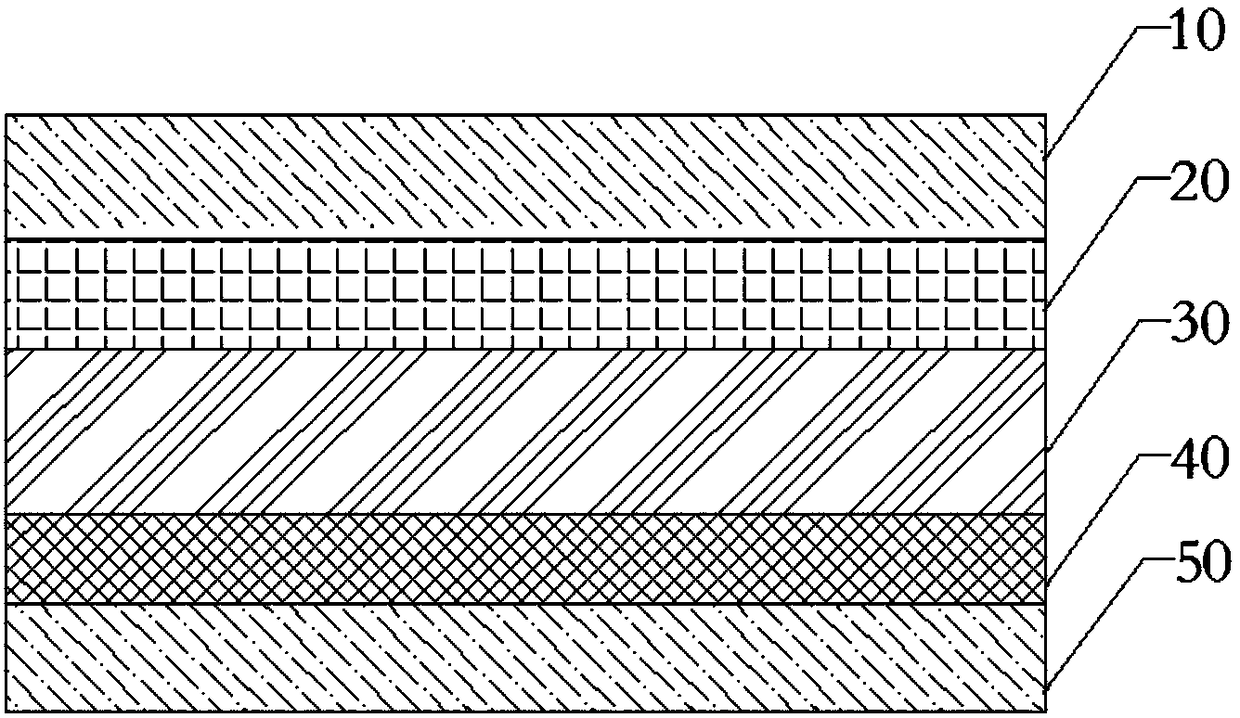

Image

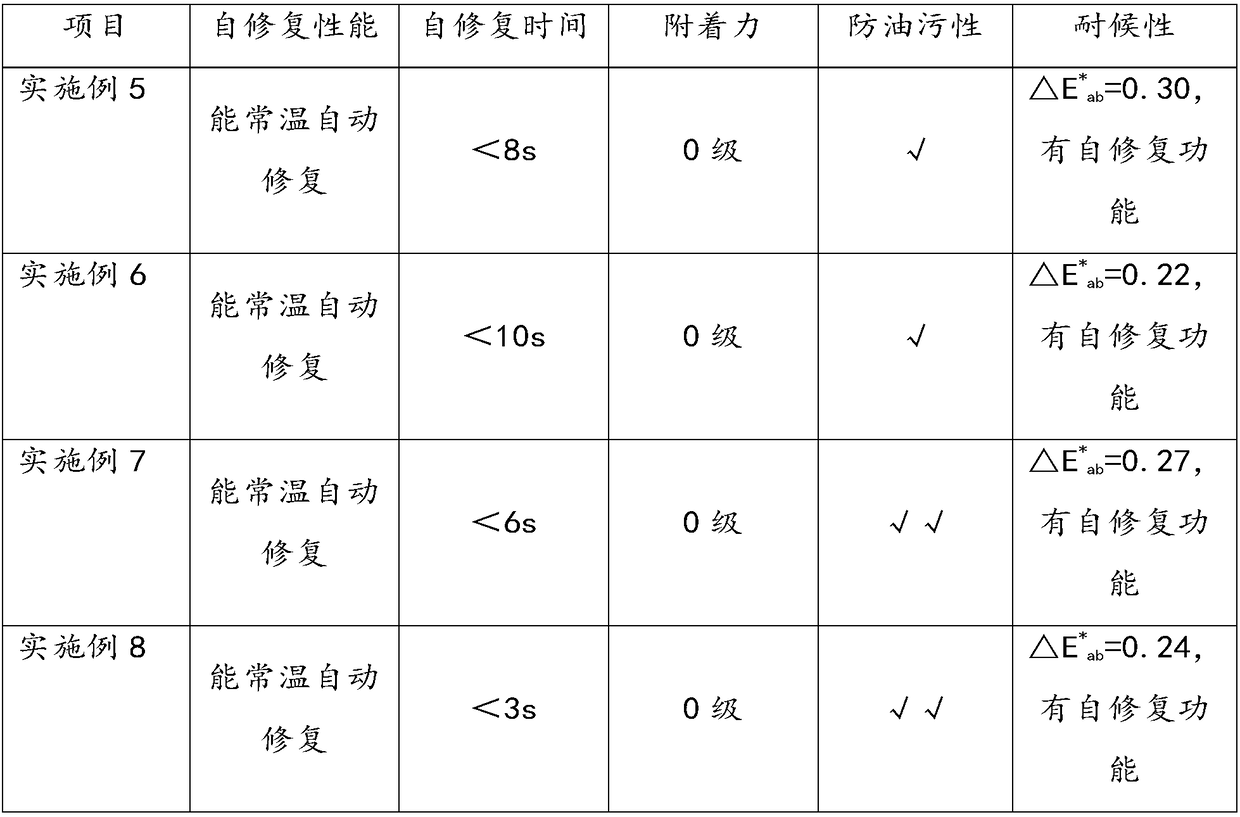

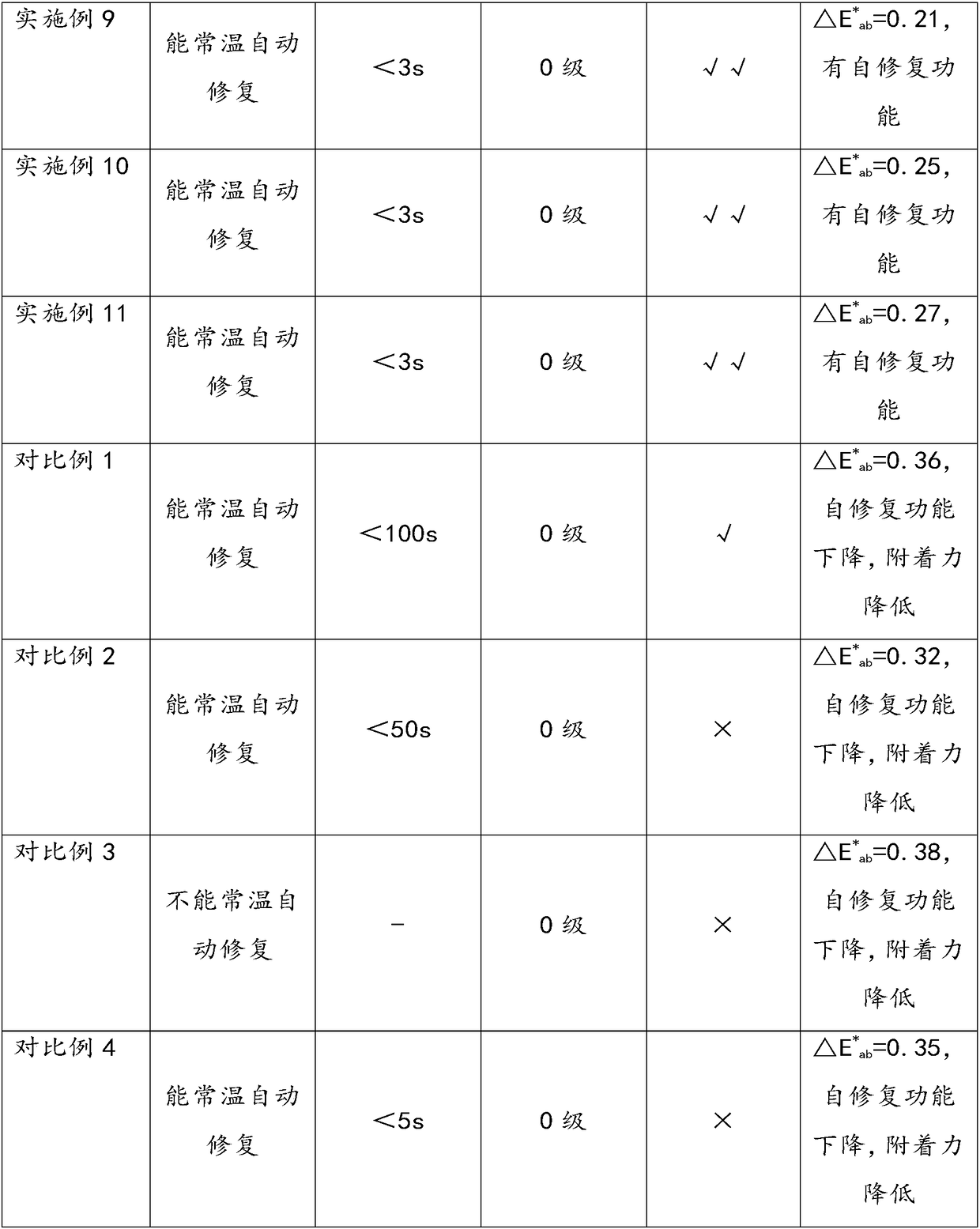

Examples

preparation example Construction

[0071] In a second aspect, a method for preparing the above-mentioned self-repairing oil-repellent coating is provided, comprising the following steps:

[0072] (a) earlier the polyhydric alcohol of formula quantity is mixed with solvent;

[0073] (b) add the auxiliary agent of formula quantity again and mix;

[0074] (c) Then add and mix the isocyanate, ultraviolet absorber and antistatic agent in the formulated amount to obtain the self-repairing anti-oil stain coating.

[0075] The preparation method of the self-repairing anti-oil pollution coating of the present invention is simple to operate and easy to implement. By mixing the raw materials separately, it helps to improve the uniformity of mixing, facilitates molding, improves stability, and then enhances the use performance of the material .

[0076] In the preparation of the self-repairing anti-oil stain coating, the above-mentioned raw material components can be mixed step by step at room temperature, and then store...

Embodiment 1

[0103] A self-repairing anti-oil stain coating, mainly made of the following raw materials in parts by weight:

[0104] 10 parts of polyester polyol, 1 part of modified polyisocyanate, 1 part of polysiloxane, 0.1 part of benzophenone ultraviolet absorber, 0.01 part of polyether polymer antistatic agent and 5 parts of ethyl acetate.

Embodiment 2

[0106] A self-repairing anti-oil stain coating, mainly made of the following raw materials in parts by weight:

[0107] 80 parts of polyether polyol, 50 parts of modified polyisocyanate, 10 parts of polysiloxane, 10 parts of benzophenone ultraviolet absorber, 10 parts of polyether polymer antistatic agent and 50 parts of ethyl acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com