Microcapsule preparation method and product thereof

A technology of microcapsule and powder embedding, which is used in food forming, food science, application and other directions, can solve the problems of difficult to ensure product quality, easy inactivation of active ingredients, and high temperature required for evaporation, and achieves improved embedding performance, Good fluidity and the effect of improving the encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

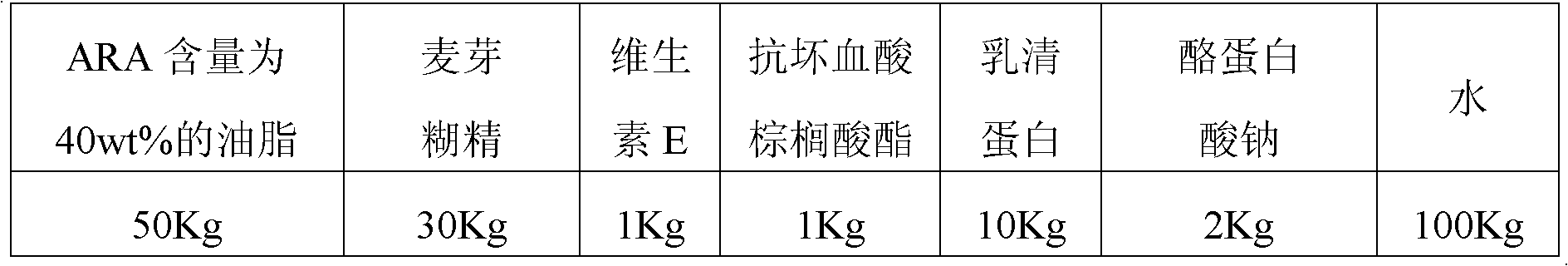

[0024] Table 1

[0025]

[0026] After mixing the ingredients described in Table 1 at 60°C, homogenize under a homogeneous pressure of 70MPa to form a uniform emulsion, then keep warm at 90°C for 3 minutes, and sterilize; then use a high-pressure pump to spray the emulsion through an atomizing spray gun Turn into liquid droplets and spray into the preheated boiling drying bed. The atomization pressure of the pressure atomization is 1-2MPa. The bottom of the boiling drying bed is pre-installed with 100Kg lactose. The drops meet the lactose in boiling fluidized state, and are wrapped and dried by lactose. At the same time, lactose is continuously added to the boiling drying bed, and the dried material is continuously sucked out from the boiling drying bed and sieved to obtain arachidonic acid. Oil microencapsulation products. The separated lactose is sent back to the fluidized drying bed through the conveying system for reuse.

[0027] The product in the obtained arachidoni...

Embodiment 2

[0029] Table 2

[0030] DHA algae oil

sodium caseinate

Vitamin E

water

60Kg

40Kg

3Kg

20Kg

2Kg

150Kg

[0031] After mixing the ingredients described in Table 2 at 80°C, homogenize under a homogeneous pressure of 60 MPa to form a uniform emulsion, and then send the emulsion into the air-flow spray gun and atomize it into the fluidized drying bed through the delivery pump The bottom of the fluidized drying bed is pre-installed with 100Kg of lactose powder embedding material. Under the action of hot air at 40°C, the atomized droplets meet the powder embedding material in a boiling fluidized state, and are wrapped and dried by the powder embedding material. At the same time, vacuum feeding equipment is used to continuously replenish lactose and tricalcium phosphate powder into the fluidized drying bed, and continuously suck the materials from the fluidized drying bed into the fluidized bed for...

Embodiment 3

[0034] table 3

[0035] 40% Arachidonic Oil

Ascorbyl Palmitate

water

30%

5%

1.5%

14%

49.5%

[0036] The ingredients described in Table 3 were mixed and emulsified at 60°C, homogenized under a homogeneous pressure of 80MPa to form a uniform emulsion, and then kept at 90°C for 3min and sterilized; The flow rate is sent to the centrifugal spray drying tower with a built-in fluidized bed for centrifugal atomization. The atomization speed is 2000-3500r / min. The inlet air temperature of the tower is 180°C. At the same time, lactose is added to the spray drying tower at a speed of 65kg / h, and the material is continuously discharged from the outlet of the built-in fluidized bed at a speed of 100kg / h, and is sieved through a 120-mesh sieve to separate Arachidonic acid oil microcapsules, the separated lactose is returned to the drying tower through the conveying system for reuse.

[0037] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com