High glowing filament environmental-friendly inflaming retarding reinforced polybutylece terephthalate (PBT)/acrylonitrile butadiene styrene (ABS) alloy material and preparation method thereof

A high-glow wire and alloy material technology, applied in the field of PBT/ABS alloy materials, can solve the problem of not being suitable for low-voltage electronic capacitor shells, etc., and achieve the effects of reducing friction coefficient, short residence time, and preventing decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0028] A method for preparing a high-glow wire environment-friendly flame-retardant reinforced PBT / ABS alloy material is characterized in that the method is as follows: raw materials are weighed according to the weight ratio: PBT 22.5%, its intrinsic viscosity is 0.88dL / g, ABS 22.5% %, compound flame retardant 20%, antimony trioxide 4.8%, glass fiber 20%, commercially available ethylene-methyl acrylate-glycidyl methacrylate random terpolymer 10%, antioxidant ( 1330) 0.1%, silicone 0.1%; put it into a high mixer and mix for 2 minutes, discharge, and then use a twin-screw extruder to extrude and pelletize. The processing temperature is 230°C and the screw speed is 30HZ.

[0029] The compound flame retardant is formed by mixing three components, and its mass percentage is BPS: 50%; MPP: 25%; talcum powder: 25%.

Embodiment 4

[0031] A method for preparing a high-glow wire environment-friendly flame-retardant reinforced PBT / ABS alloy material is characterized in that the method is as follows: raw materials are weighed according to the weight ratio: PBT 25%, its intrinsic viscosity is 0.90dL / g, ABS 41 %, compound flame retardant 6%, antimony trioxide 3%, glass fiber 21%, commercially available ethylene-methyl acrylate-glycidyl methacrylate random terpolymer 2%, antioxidant ( 1330) 1%, silicone 1%; put it into a high mixer and mix for 5 minutes, discharge, and then use a twin-screw extruder to extrude and pelletize. The processing temperature is 240°C and the screw speed is 40HZ.

[0032] The compound flame retardant is formed by mixing three components, and its mass percentage is BPS: 50%; MPP: 25%; talcum powder: 25%.

[0033] The glass fiber is an alkali-free glass fiber, and the glass fiber is added into the silane coupling agent to make its surface treated with the silane coupling agent.

Embodiment 5

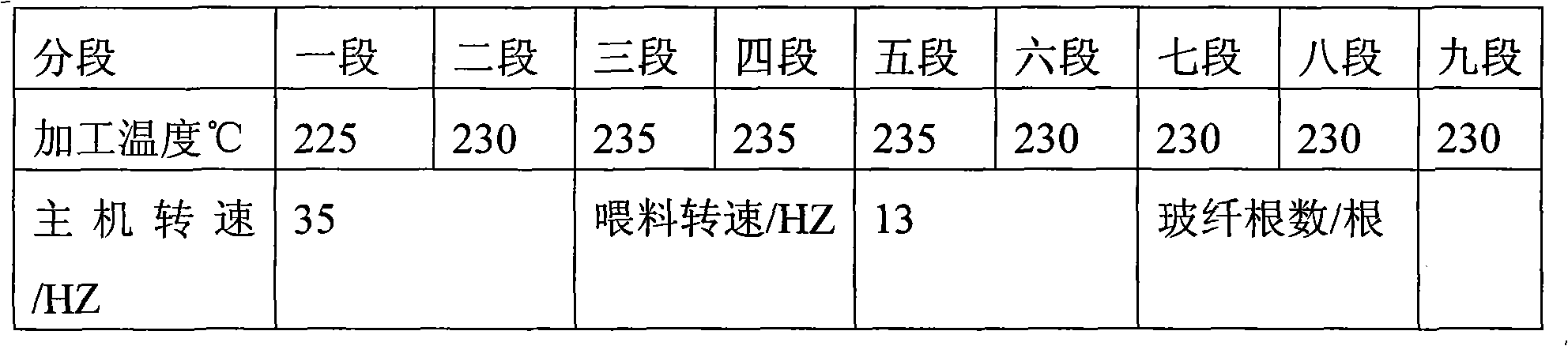

[0035] A method for preparing a high-glow wire environment-friendly flame-retardant reinforced PBT / ABS alloy material is characterized in that the method is as follows: raw materials are weighed according to the weight ratio: PBT 23%, its intrinsic viscosity is 0.88dL / g, ABS 23% , compound flame retardant 6%, antimony trioxide 15%, glass fiber 30%, commercially available ethylene-methyl acrylate-glycidyl methacrylate random terpolymer 2%, antioxidant (1330 ) 0.5%, silicone 0.5%; put it into a high mixer and mix for 3 minutes, discharge, and then use a twin-screw extruder to extrude and pelletize. The processing temperature is 235°C and the screw speed is 35HZ.

[0036] The compound flame retardant is formed by mixing three components, and its mass percentage is BPS: 50%; MPP: 25%; talcum powder: 25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com