Synthetic leather surface conditioning agent

A technology of surface treatment agent and synthetic leather, which is applied in fiber treatment, fiber type, textiles and papermaking, etc. It can solve the problems of environmental pollution, production cost, toxic solvents, single variety, etc., and achieve good matting effect, good transparency, and return good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

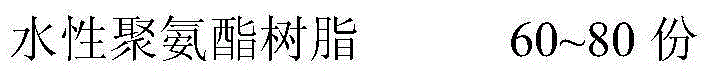

Method used

Image

Examples

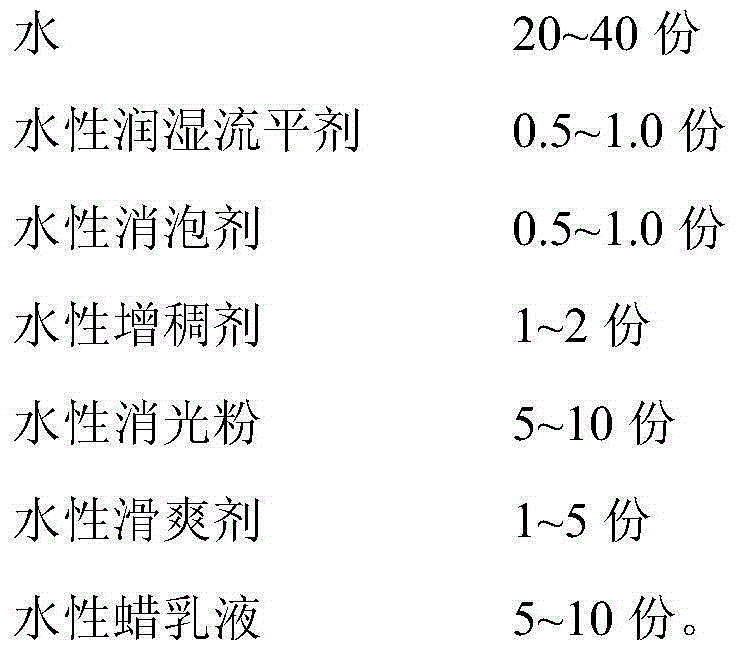

Embodiment 1

[0038] Take 60kg of water-based polyurethane resin KT632 (Hefei Ketian Chemical) and put it into the mixer, add 0.5kg of water-based wetting and leveling agent tego245 (Germany Tego), 1kg of water-based slip agent BD-3367 (Hangzhou Bolder Silicone) and Mix and stir 0.5kg water-based defoamer A34 (Shenzhen Haichuan Chemical); during the stirring process, add 5kg water-based matting powder 520L (Beijing Aerospace Saide), 5kg water-based wax emulsion E340 (Weng Kaier) and 40kg of ordinary tap water, continue Stir for 20 minutes, and filter the mixture with a 200-mesh filter cloth; finally put the filtered mixture into the mixer, add 1kg of water-based associative thickener 3551 (Shenzhen Haichuan Chemical Industry), and stir well to obtain the surface of water-based polyurethane synthetic leather. treatment agent.

Embodiment 2

[0040] Take 65kg of water-based polyurethane resin KT635 (Hefei Ketian Chemical) into the mixer, add 0.6kg of water-based wetting and leveling agent tego270 (Germany Tego), 1.2kg of water-based silicone slip agent DC3667 (USA Dow Corning) and 0.6kg of water-based disinfectant Foaming agent 4386 (Ashland, USA) is mixed and stirred; during the stirring process, add 6kg of silica water-based matting powder M4 (Abemarle, USA), 6kg of water-based silicone wax emulsion E360 (Weng Kaier) and 35kg of ordinary tap water , continue to stir for 20 minutes, and filter the mixture with a 200-mesh filter cloth; finally, put the mixture obtained above into a blender, add 1.2kg of water-based associative thickener 3329 (Shenzhen Haichuan Chemical Industry), and stir well to obtain a water-based thickener. Polyurethane surface treatment agent.

Embodiment 3

[0042] Take 70kg of water-based polyurethane resin KT637 (Hefei Ketian Chemical) and put it into the mixer, add 0.8kg of water-based wetting and leveling agent tego245 (Germany Tego), 1.5kg of water-based silicone slip agent DC3667 (USA Dow Corning) and 0.8kg The water-based defoamer 4386 (Ashland, USA) was mixed and stirred; during the stirring process, 8kg of silicon dioxide water-based matting powder 520L (Beijing Aerospace Saide), 8kg of water-based silicone wax emulsion E340 (Weng Kaier) and 30kg of ordinary tap water, continue to stir for 20 minutes, and filter the mixture with a 200-mesh filter cloth; finally, put the mixture obtained above into a blender, add 1.5kg of water-based associative thickener 3329 (Shenzhen Haichuan Chemical Industry), and stir evenly After that, the water-based polyurethane surface treatment agent is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com