Apple bagging mechanism

A technology of bagging and apples, applied in the direction of plant protection covers, etc., can solve the problems of imperfect technology, time-consuming, laborious, tedious and tiring, etc., and achieve the effect of simple sealing, precise position and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

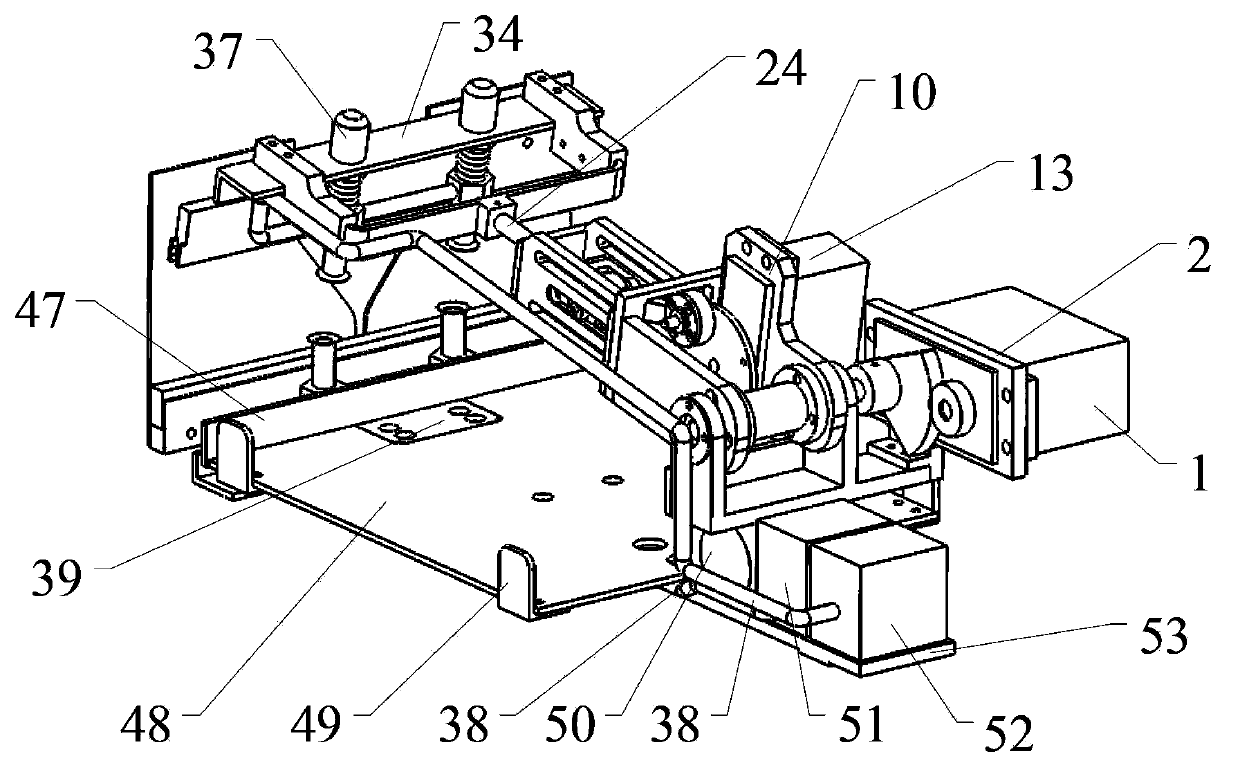

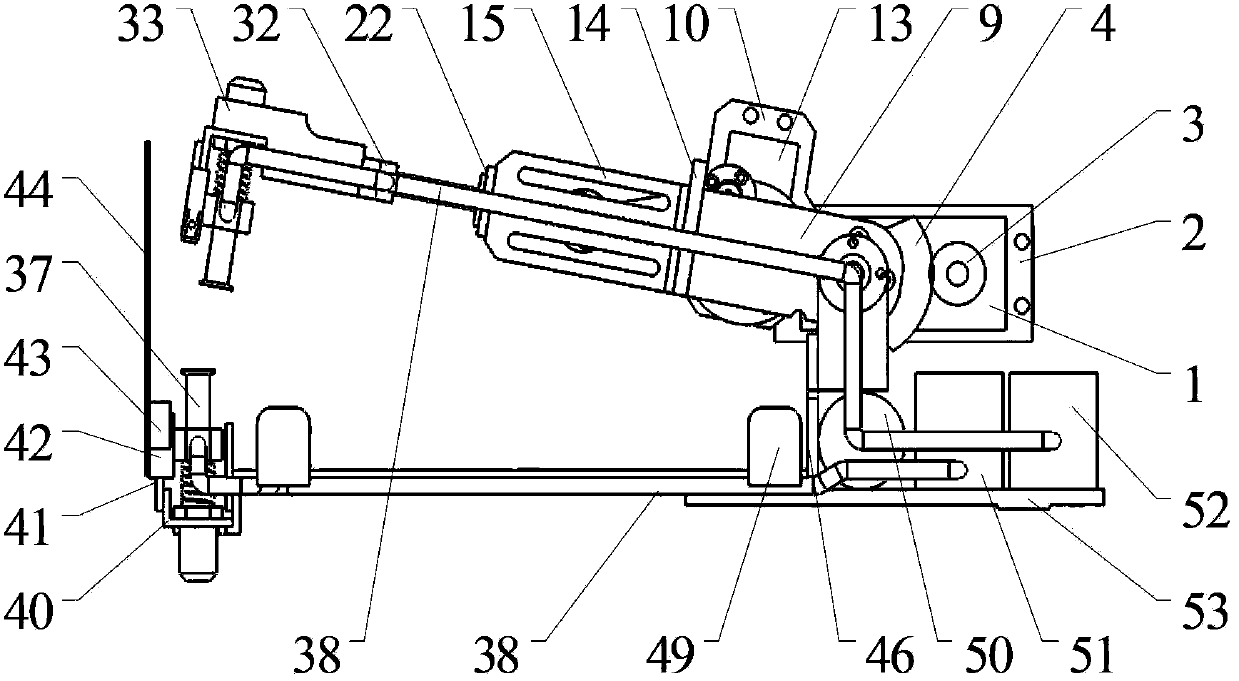

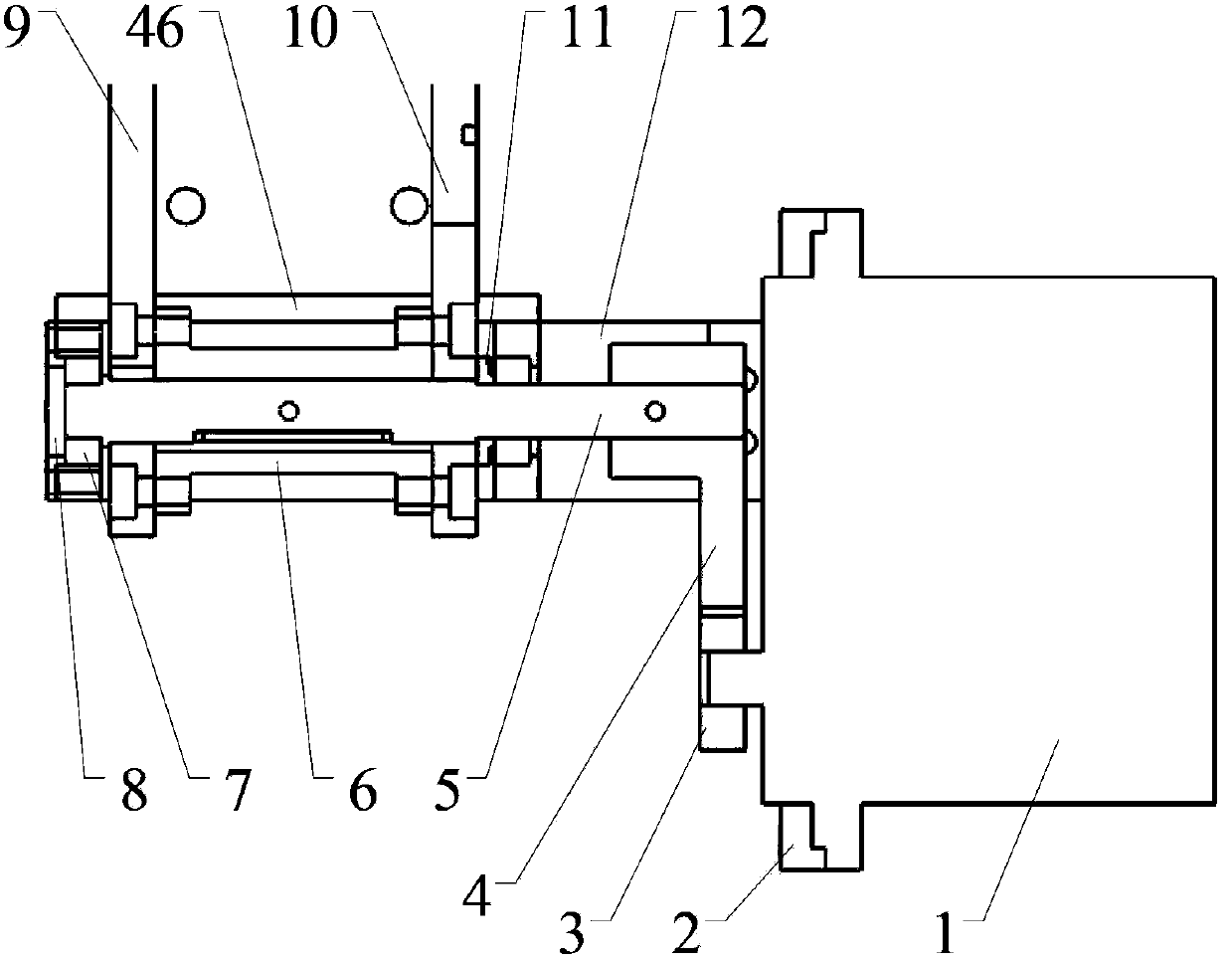

[0036] Such as figure 1 , figure 2As shown, the whole of the present invention is installed on the mechanical arm by mechanically connecting the bottom plate 53, including a fruit bag device, a pitching device, a telescopic device, an upper sticky bag device, a lower sticky bag device and an air suction device, wherein the fruit bag device and the suction machine The air device is directly fixed on the mechanical arm connection base plate 53 respectively, the pitching device is installed on the fruit bag device, the telescopic device is connected with the pitching device, and is driven by the pitching device to swing around the pitching support shaft 5; the upper sticking bag device is connected to The output end of the telescopic device is driven to expand and contract by the telescopic device, and together with the telescopic device, it swings around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com