Organosilicon fluorine multifunctional fabric finishing agent and preparing method thereof

A fabric finishing agent and multi-functional technology, applied in fiber treatment, textiles and papermaking, etc., can solve the problems of easy oil drift, easy delamination, high environmental requirements, etc., and achieve simple preparation process, strong emulsion stability, excellent Water and oil repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

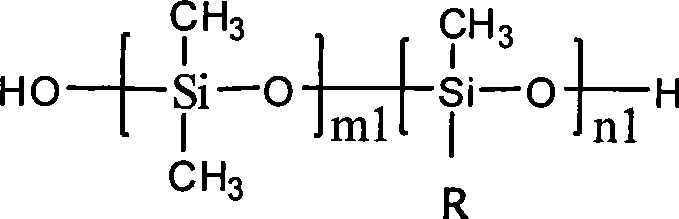

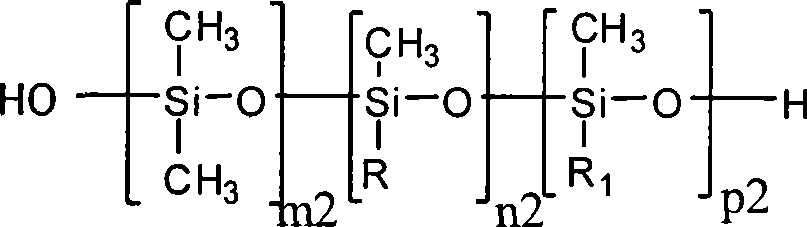

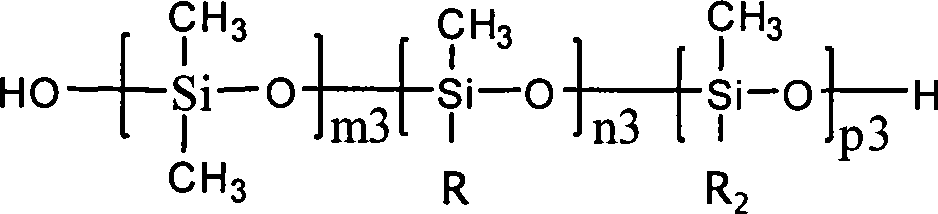

Method used

Image

Examples

Embodiment 1

[0036] In parts by weight, 20 parts of amino silicone oil, 5 parts of long carbon chain modified amino silicone oil, 5 parts of fluorine-containing modified silicone oil, 10 parts of emulsifier (the mass ratio of AEO-3 and AEO-9 is 1:1), positive 3 parts of butanol, stirred for 10 minutes, then added 30 parts of deionized water, stirred for 20 minutes, added 0.5 parts of glacial acetic acid to adjust the pH value to 6-7, added deionized water to 100 parts, stirred for 1-2 hours, and emulsified to obtain a transparent emulsion.

Embodiment 2

[0038] In parts by weight, 15 parts of amino silicone oil, 10 parts of long carbon chain modified amino silicone oil, 5 parts of fluorine-containing modified silicone oil, 10 parts of emulsifier (the mass ratio of AEO-9 and XP50 is 2:1), 3 parts of n-hexanol parts, stirred for 10 minutes, then added 30 parts of deionized water, stirred for 20 minutes, added 0.5 parts of glacial acetic acid to adjust the pH value to 6-7, added deionized water to 100 parts, stirred for 1-2 hours, and emulsified to obtain a transparent emulsion.

Embodiment 3

[0040] In parts by weight, 10 parts of amino silicone oil, 15 parts of long carbon chain modified amino silicone oil, 5 parts of fluorine-containing modified silicone oil, 10 parts of emulsifier (the mass ratio of AEO-3 and AEO-9 is 2:3), positive 3 parts of butanol, stirred for 10 minutes, then added 30 parts of deionized water, stirred for 20 minutes, added 0.7 parts of glacial acetic acid to adjust the pH value to 6-7, added deionized water to 100 parts, stirred for 1-2 hours, and emulsified to obtain a transparent emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com