Acrylic-amino type coating varnish composition for automobiles, varnish and application thereof

A technology of overcoating varnish and composition, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

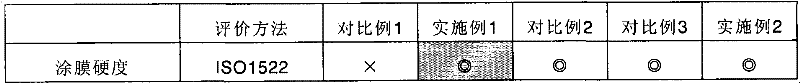

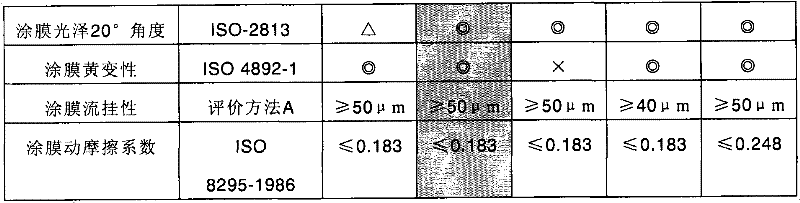

Examples

Embodiment 1

[0081] formula:

[0082] The same as Comparative Example 1, the difference is that component ① is 20-40 parts by weight of high solids hydroxyl-containing acrylic resin (solids ≥ 70%, molecular weight 3000-5000) with a hydroxyl value of 130;

[0083] Preparation method: Add ① high solid hydroxyl-containing acrylic resin, ② n-butanol etherified melamine resin, ③ blocked polyisocyanate resin, ④ diurea compound modified polyacrylic resin, ⑩ part of the diluent, and stir with a mixer 30min. Then use ⑩partial diluent to dissolve ⑤ultraviolet absorber solid powder ⑥light stabilizer at 50-60℃ to a clear liquid without particles. While stirring, add the above-dissolved ultraviolet light diluent and ⑥ light stabilizer in sequence. Finally, use the remaining part and ⑩thinner to adjust the viscosity of the paint to a suitable viscosity.

[0084] Usage: Same as Comparative Example 1

Embodiment 2

[0096] formula:

[0097] 1. 20 parts by weight of high solids hydroxyl-containing acrylic resin (solids ≥ 70%, molecular weight 3000-5000) with a hydroxyl value of 130;

[0098] 2. 20 parts by weight of the melamine resin of n-butanol etherification;

[0099] 3. 1 weight part of aliphatic polyisocyanate resin blocked by 5-dimethylpyrazole (DMP);

[0100] 4. 10 parts by weight of polyacrylic resin modified by diurea compound (modified amount is 3.2-4.2% by weight);

[0101] 5. 2 parts by weight of benzotriazole ultraviolet light absorber;

[0102] 6. 0.5 parts by weight of hindered amine light stabilizer;

[0103] ⑦1.0 parts by weight of polyester modified polydimethylsiloxanes to reduce surface tension leveling agent;

[0104] ⑧Acrylic ester leveling agent 0.1 parts by weight;

[0105] ⑨ Acrylic defoamer 1 part by weight;

[0106] ⑩Diluent 10 parts by weight

[0107] Preparation method: with embodiment 1

[0108] Usage: Same as Comparative Example 1

Embodiment 3

[0110] The formula is similar to that of Example 1, except that component ① has a hydroxyl value of 150 and does not contain a defoamer.

[0111] Preparation method: Add ① high solid hydroxyl-containing acrylic resin, ② n-butanol etherified melamine resin, ③ blocked polyisocyanate resin, ④ diurea compound modified polyacrylic resin, ⑩ part of the diluent, and stir with a mixer 30min. Then use ⑩ part of the diluent to dissolve ⑤ UV absorber solid powder at 50-60°C to a clear liquid without particles. In the state of stirring, add the above-dissolved UV diluent, ⑥ light stabilizer and leveling agent in sequence. Finally, use the remaining part and ⑩thinner to adjust the viscosity of the paint to a suitable viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com