Numerically-controlled milking composite machine tool

A compound machine tool and machine tool technology, applied in turning equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of complex processing programs, high requirements for operators' comprehensive quality and technical level, complex structure, etc. The effect of safe operation, good rigidity of the whole machine and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the schematic structural diagram of the invention and specific embodiments.

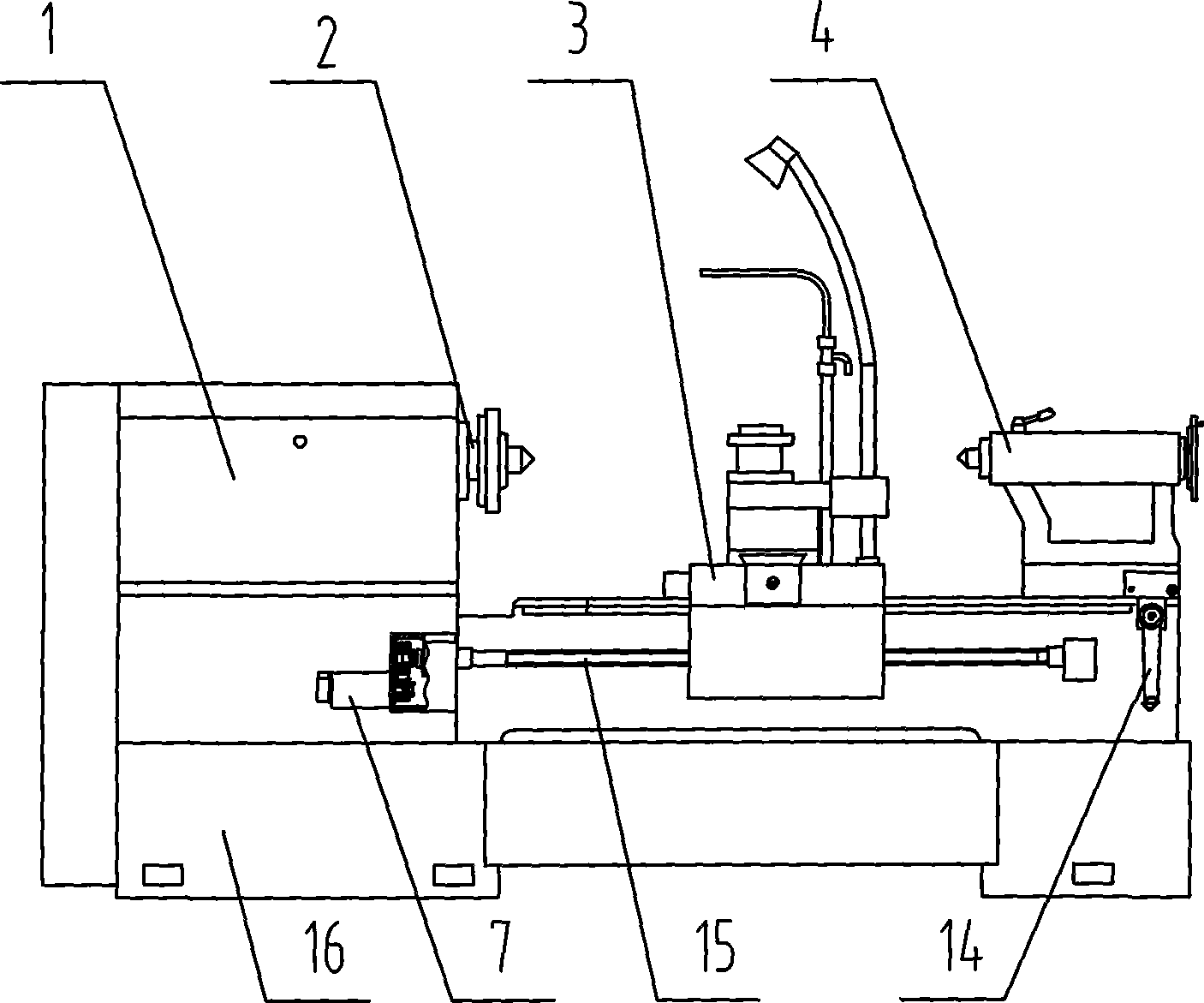

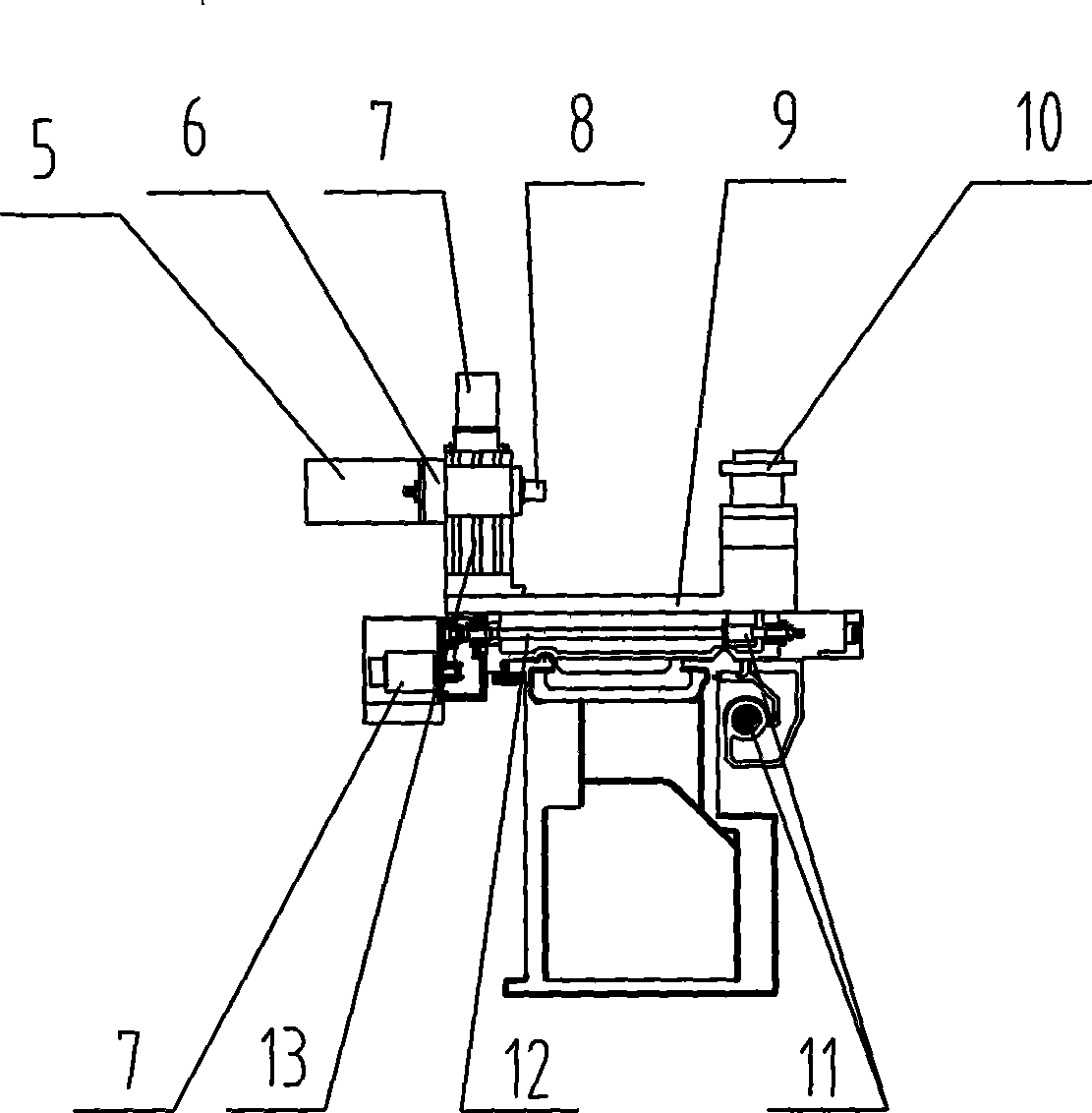

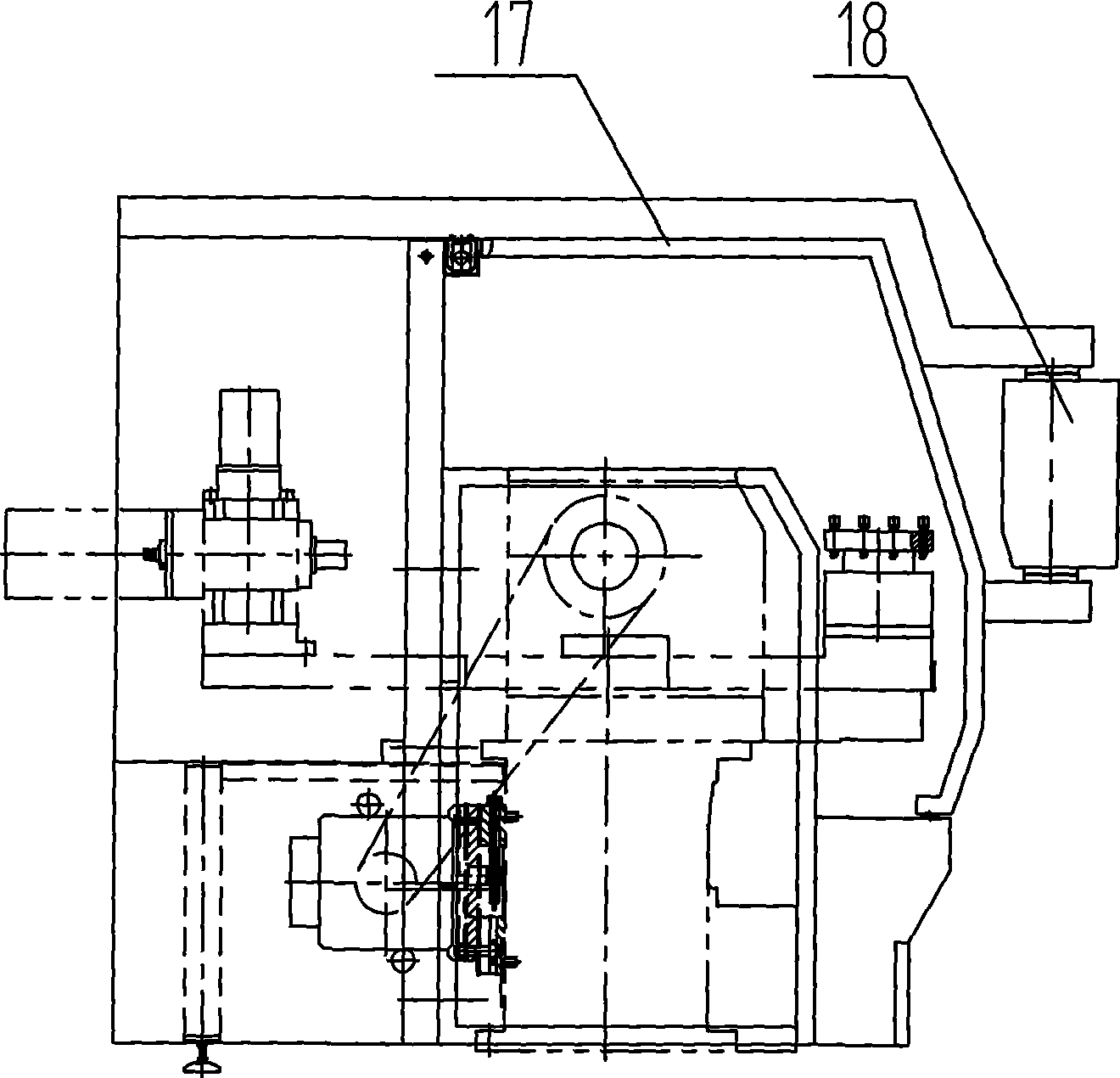

[0017] The bed 16 of the machine tool adopts an integral floor type, and there is only one main shaft 2 in the bed head box of the machine bed, and the main motor of the machine tool adopts a high-performance servo main shaft motor, which is transmitted to The spindle 2 inside the bedside box 1 has a spindle speed range of 10 to 800r / min, which can realize stepless speed regulation and constant speed cutting, with small temperature rise and thermal deformation. The spindle has a C-axis function that can be accurately indexed. Accuracy up to 3'. The lower block 9 is housed on the machine tool saddle 3, and the rear end of the lower block 9 is equipped with a liftable milling power head 6, and the lifting of the milling power head 6 is realized by the rotation of the ball screw pair 11 driven by the servo motor 7. The mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com