Imidazole compound, metal surface treatment liquid, metal surface treatment method, and laminate production method

一种金属表面处理、咪唑化合物的技术,应用在咪唑化合物、金属表面处理液、金属的表面处理、及层合体的制造领域,能够解决布线易发生短路等问题,达到氧化优异、氧化抑制的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

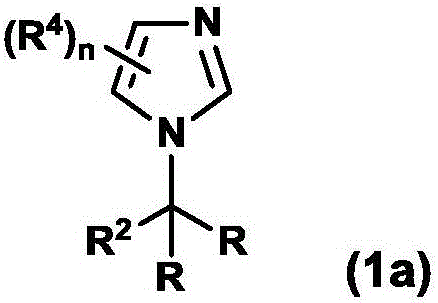

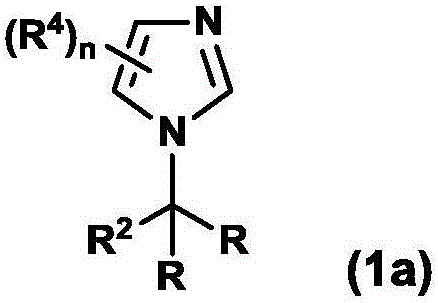

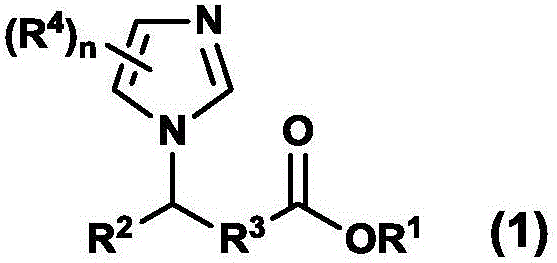

[0138] In Example 1-1, an imidazole compound having the following structure was synthesized as Additive 1.

[0139]

[0140]

[0141] 400 g of the raw material compound (1-(3-(4-methoxyphenyl)acryloyl)imidazole) having the structure of the above formula was put into a drier together with water, and heated at 60° C. for 1 month. This was repulped and washed with 4000 g of ethyl acetate at room temperature, and filtered and rinsed twice with 400 g of ethyl acetate to obtain a wet powder 1 . Wet powder 1 was reslurried and washed with 4000 g of ethyl acetate again, and filtered and rinsed twice with 400 g of ethyl acetate to obtain wet powder 2 . The wet powder 2 was dried at 40° C. under reduced pressure to obtain 300 g of the target additive 1 (3-imidazolyl-3-(4-methoxyphenyl)propionic acid). The purity of Additive 1 was determined to be above 99.9% by HPLC.

[0142] determination 1 The results of H-NMR are shown below.

[0143] 1 H-NMR (DMSO-d6): 7.82(1H), 7.31-7.40...

Embodiment 1-2

[0157] 380 g of Additive 1 was obtained in the same manner as in Example 1-1, except that 4 g of imidazole was added to 400 g of the raw material compound and the heating time was changed from 1 month to 2 weeks. The purity of the obtained Additive 1 was determined to be 99.9% or more by HPLC.

Embodiment 1-3

[0159] First, 30 g of the raw material compound used in Example 1-1 was dissolved in 200 g of methanol, and then 7 g of potassium hydroxide was added to the methanol. Next, the methanol solution was stirred at 40°C. Methanol was distilled off, and the residue was suspended in 200 g of water. To the obtained suspension, 200 g of tetrahydrofuran was mixed, stirred, and the aqueous phase was liquid-separated. Under ice cooling, 4 g of hydrochloric acid was added and stirred, and then 100 g of ethyl acetate was mixed and stirred. The mixture was allowed to stand, and the oily phase was separated. The target substance was crystallized from the oil phase, and the precipitate was recovered to obtain Additive 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight-average Molecular Weight | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

| molecular weight dispersion degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com