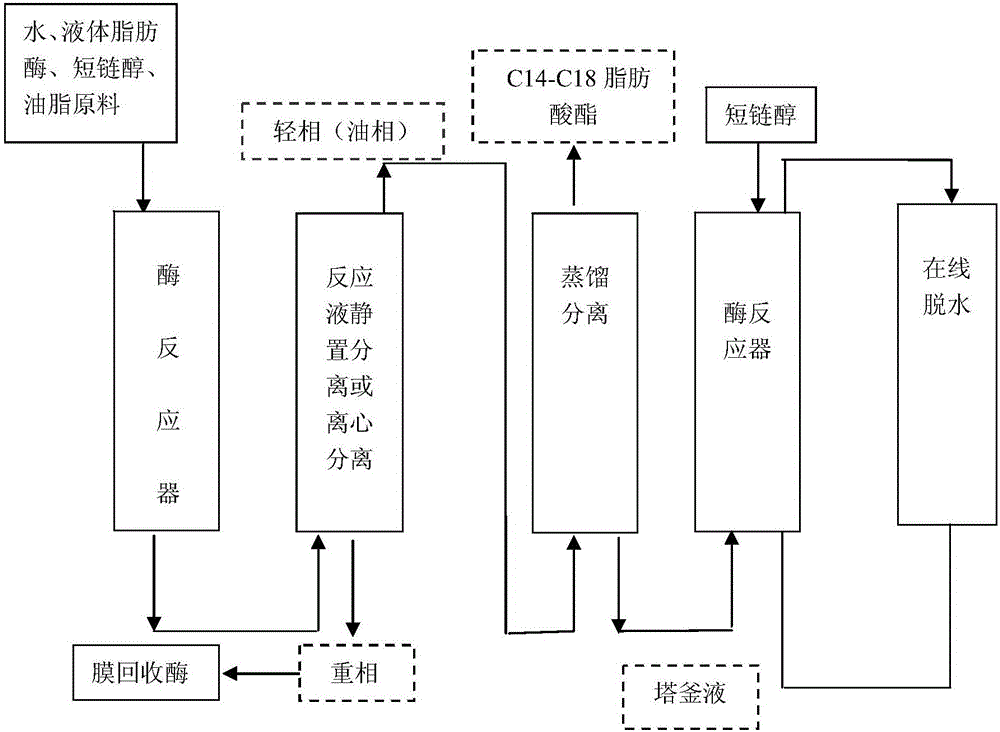

Coupling process for preparing biodiesel and enriching polyunsaturated fatty acid esters

A fatty acid ester and biodiesel technology, applied in biofuels, fermentation, etc., can solve the problems of high energy consumption, high cost, and poor selectivity in the process, and achieve the effects of high product yield, strong applicability, and environmentally friendly and clean process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 10g Botryococcus sp. Microalgae oil (containing eicosapentaenoic acid and docosahexaenoic acid, water based on 10% of oil quality and 200 standard enzyme activities (200U / g soybean oil) based on unit oil quality The liquid lipase derived from Candida antarctica (Candida antarctica) is placed in a one-stage or multi-stage enzyme reactor suitable for enzyme catalysis. The temperature is controlled at 35°C, and then the ethanol based on the molar ratio of oil and fat is 4.5:1 in Add at a constant speed within 3 hours. After 6 hours of reaction, the fatty acid carbon chain length is that the oil of C14-C18 is converted into the corresponding fatty acid ethyl ester (92% conversion rate), and then the reaction solution is phase-separated to separate the enzyme-containing Heavy phase and light phase (oil phase). The heavy phase further utilizes membrane separation to reclaim enzyme protein, selects the organic membrane that molecular weight cut off is 15000 to carry out the rec...

Embodiment 2

[0024] 10g of C.vulgaris microalgae oil (containing eicosapentaenoic acid), 5% water based on oil quality and liquid lipase derived from Aspergillus oryzae (Aspergillus oryzae) based on 200 standard enzyme activities per unit oil quality, Placed in a one-stage or multi-stage enzyme reactor suitable for enzyme catalysis. Control the temperature at 40°C, and then add methanol with a molar ratio of 6:1 based on oil at a uniform rate within 4 hours. After reacting for 8 hours, oils with fatty acid carbon chain lengths of C14-C18 were converted into corresponding fatty acid methyl esters (the conversion rate was 93%). Then the reaction solution is centrifuged to separate the enzyme-containing heavy phase and light phase (oil phase). In the heavy phase, the enzyme protein is further recovered by membrane separation, and an organic membrane with a molecular weight cut-off of 15,000 is selected for the recovery of the above-mentioned lipase. The recovery rate of the enzyme protein is...

Embodiment 3

[0026] 10g fish oil (containing arachidonic acid, C20:4) is based on the water of 2% of oil quality and based on the liquid lipase derived from Thermomyces lanuginosus (Thermomyces lanuginosus) of 200 standard enzyme activities based on unit oil quality and based on unit The liquid lipase derived from Aspergillus oryzae (Aspergillus oryzae) with an oil quality of 200 standard enzyme activities is placed in a one-stage or multi-stage enzyme reactor suitable for enzyme catalysis. Control the temperature at 45°C, and then add ethanol with a molar ratio of 6:1 based on oil at a constant speed within 2 hours. Reaction 5 hours, fatty acid carbon chain length is that the oil of C14-C18 is converted into corresponding fatty acid ethyl ester (93% of conversion rate), then reaction solution is carried out centrifugation, separates the heavy phase and light phase (oily phase) containing enzyme Mutually). In the heavy phase, the enzyme protein is further recovered by membrane separation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com