Lubricant additive and lubricant composition

a technology of additives and lubricants, applied in the direction of lubricant compositions, liquid carbonaceous fuels, fuels, etc., to achieve excellent wear resistance, low friction coefficient, and sufficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0054]Next, the invention will be described in a further detail with reference to Examples, which by no means limit the invention.

[0055]Specifically, lubricating oil compositions as determined below were prepared, and the lubricating properties thereof (friction coefficients and wear resistance) were evaluated.

[0056]The components used for preparing the lubricating oil compositions are as follows.

(1) Base Oil:

[0057](1-1) Base oil A: mineral oil of 500 neutral fraction (HG500)

[0058](1-2) Base oil B: commercially-available oil containing antioxidants, antiwear agents and the like (general-purpose oil exemplarily used as gear oil)

(2) Additives

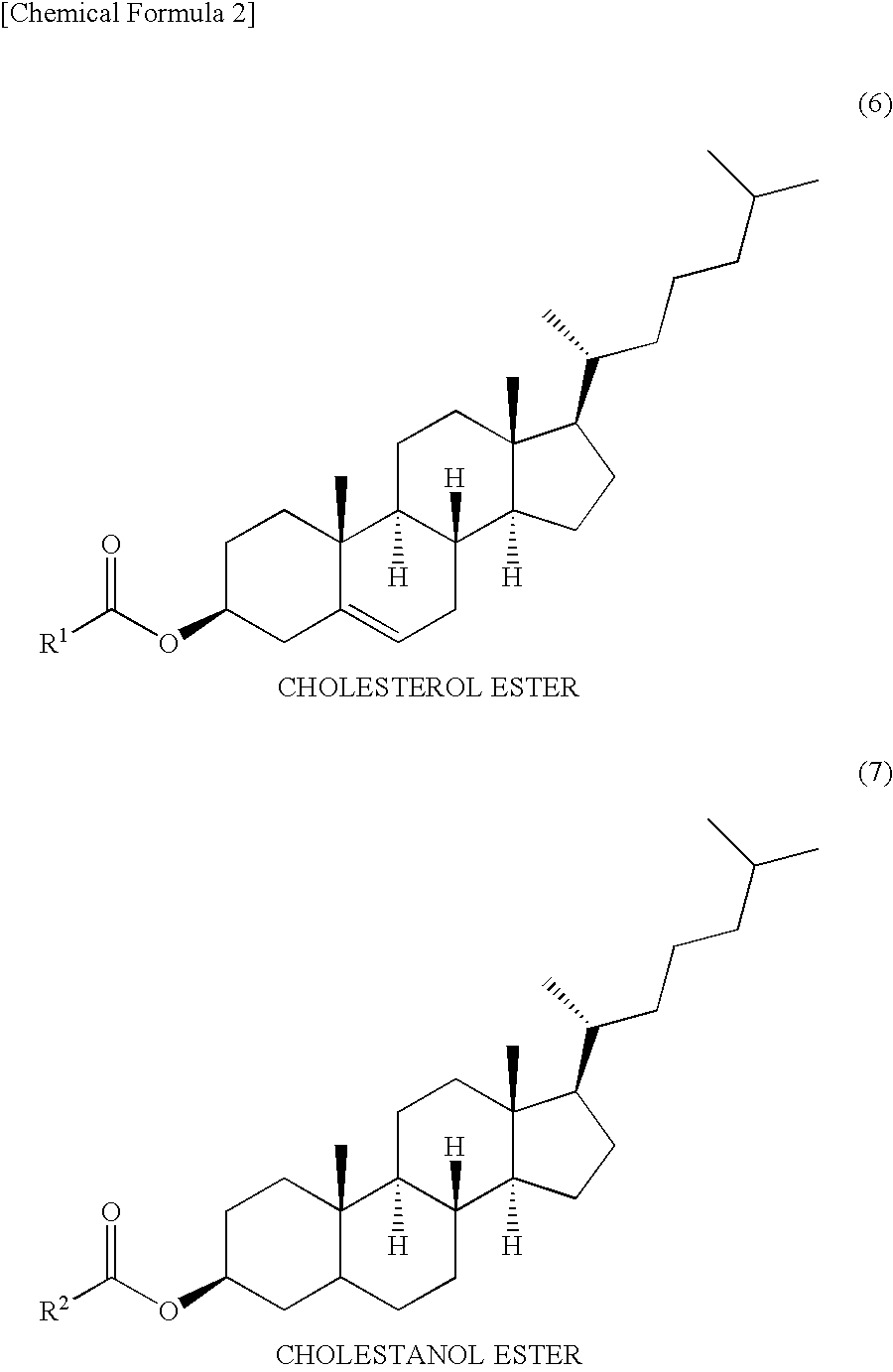

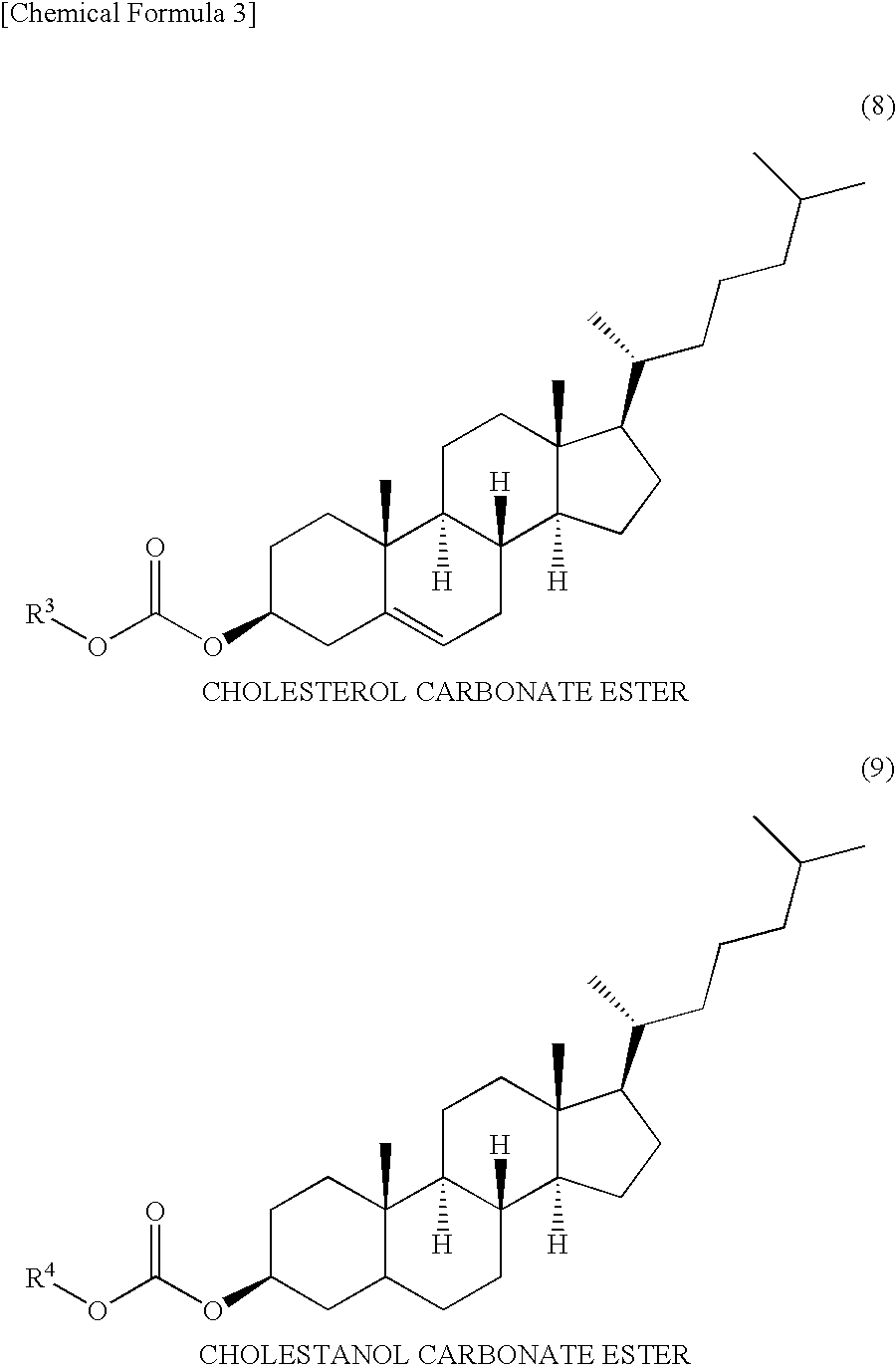

[0059](2-1) FM A: cholesterol stearate (manufactured by Wako Pure Chemical Industries, Ltd.)

[0060](2-2) FM B: cholesterol n-caprylate (manufactured by Tokyo Chemical Industry Co., Ltd.)

[0061](2-3) FM C: cholesterol acetate (manufactured by Tokyo Chemical Industry Co., Ltd.)

[0062](2-4) FM D: cholesterol n-octyl carbonate (manufactured by Tokyo Chem...

example 13

[0073]98.7 mass % of the base oil A (HG500), 0.3 mass % of a phenol antioxidant and 1 mass % of FM A were mixed together, and a thermal stability test (based on JIS K2540) was conducted at 120 degrees C. for 168 hours. No precipitate was observed at all.

[0074]As understandable from the above results, the lubricating oil additive according to the aspect of the invention was considerably excellent in friction-coefficient reduction and wear resistance, even though the additive contained no metal such as Mo or Zn, sulfur or phosphorus. Particularly notably, the friction reduction by the lubricating oil additive according to the aspect of the invention was much more excellent than the friction reduction by MoDTC (Comparative 1), i.e., an additive typically used so far for providing considerably excellent friction reduction. As understandable also from Examples 4 and 5, when added to commercially-available general-purpose lubricating oil, the lubricating oil additive according to the aspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com