Preparation method for fatty acid ester phase-change energy storage material

A technology of phase-change energy storage materials and fatty acid esters, which is applied in the direction of fatty acid esterification, fatty acid hydrogenation, heat exchange materials, etc., can solve the problems of restricted application and high price, and achieve low cost, low cost and high technology The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Transesterification reaction: first heat a certain amount of tallow at 100°C for 30 minutes to remove residual moisture, transfer it to a reactor equipped with baffles and stirring, and then add 10 wt% (mass fraction) of sodium propoxide to the propane The sodium alkoxide / propanol mixture is added to tallow, wherein the molar ratio of tallow and propanol is 1:6 for feeding. The reaction mixture was reacted at 85° C. for 45 minutes, and about 10 minutes after the completion of the reaction, the mixture separated into two layers. The light yellow upper layer is tallow propyl ester, while the dark yellow lower layer is glycerin. The obtained tallow propyl ester was purified by washing three times with deionized water, and at the same time, during the first water washing process, several drops of pure hydrochloric acid were added to neutralize the product.

[0036] Hydrogenation reaction: After cleaning and neutralizing the tallow propyl ester, it was added to a borate gla...

Embodiment 2

[0044] Transesterification reaction: first heat a certain amount of tallow at 100°C for 30 minutes to remove residual moisture, transfer it to a reactor equipped with baffles and stirring, then add the mixture of methanol and sodium hydroxide to the tallow , wherein the molar ratio of tallow and methanol is 1:6 for feeding, and sodium hydroxide is 0.5wt% of the tallow mass. The reaction mixture was reacted at 65° C. for 45 minutes, and after about 10 minutes after the completion of the reaction, the mixture separated into two layers. The light yellow upper layer is tallow methyl ester, while the dark yellow lower layer is glycerin. The obtained tallow methyl ester was purified by washing three times with deionized water, and at the same time, during the first washing process, a few drops of pure hydrochloric acid were added to neutralize the product.

[0045] Hydrogenation reaction: After the tallow methyl ester was washed and neutralized, it was added to a borate glass conta...

Embodiment 3

[0048] Transesterification reaction: except catalyst and operating temperature, experimental process is identical with embodiment 1. The catalyst sodium butoxide is prepared by dissolving sodium in butanol to form a butanol mixture containing 10% of the catalyst. Since the boiling point of butanol at standard atmospheric pressure is about 118°C, the reaction temperature was set at 115°C.

[0049] Hydrogenation reaction: Experimental process is identical with embodiment 1.

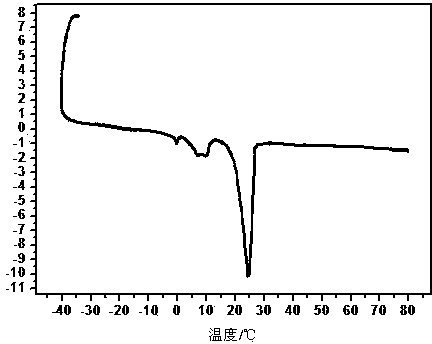

[0050] Tested by Japan Shimadzu DSC-60 differential scanning calorimeter, all butyl esters are completely converted into saturated esters, the latent heat of phase transition of tallow hydrogenated butyl ester is 124.47J / g, and the melting temperature is 22°C. The test result of this embodiment is as Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com