Nano-silver loaded activated carbon fiber and preparation method thereof

A technology of activated carbon fiber and nano-silver, applied in the direction of carbon fiber, fiber treatment, separation method, etc., can solve the problems of limited silver loading, reduced sterilization and antibacterial performance, low silver loading, etc., and achieves non-toxic reducing agent and increased dispersibility. , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Impregnation of activated carbon fibers

[0048] Weigh 0.7910g of silver nitrate and add it to 100ml of deionized water, and stir magnetically for 30min to obtain a silver source solution with a mass concentration of 0.5%. Select viscose-based SY-1500 activated carbon fiber (Shanghai Lianbing Environmental Protection, specific surface area 1300-1400m 2 / g, average pore size 17-20A. ) 4g, cut into 5cm 2 / piece, dipped into the silver source solution, fully stirred by magnetic force at room temperature for 2 hours, and the rotation speed was 500rpm.

[0049] (2) Reduction of silver

[0050] The activated carbon fibers obtained by the above impregnation are put into a vacuum drying oven, dried at 80°C, then placed in 60ml of acetone, placed in a water bath, heated at 80°C, and magnetically stirred for 10 minutes at the same time. The stirring speed is 1000rpm; Dissolve 0.1662g of lauric acid in 20ml of deionized water, dissolve 0.0961g of stearic acid in 12ml of de...

Embodiment 2

[0053] (1) Impregnation of activated carbon fibers

[0054] Weigh 3.7868g of silver acetate and add it to 110ml of deionized water, and stir it magnetically for 30 minutes to obtain a silver source solution with a mass concentration of 2%. 2 / g, average pore size 17-20A. ) 4g, cut into 5cm 2 / piece, dipped into the silver source solution, fully stirred by magnetic force at room temperature for 2 hours, and the rotation speed was 500rpm.

[0055] (2) Reduction of silver

[0056] The activated carbon fibers obtained by the above impregnation are put into a vacuum drying oven, dried at 80°C, then placed in 80ml of acetone, placed in a water bath, heated at 80°C, and magnetically stirred for 10 minutes at the same time. The stirring speed is 1000rpm; Dissolve 0.1729g of lauric acid in 18ml of deionized water, dissolve 0.1192g of stearic acid in 12ml of deionized water, dissolve 0.1571g of polyvinylpyrrolidone in 10ml of deionized water, and dissolve the three protective agent ...

Embodiment 3

[0059] (1) Impregnation of activated carbon fibers

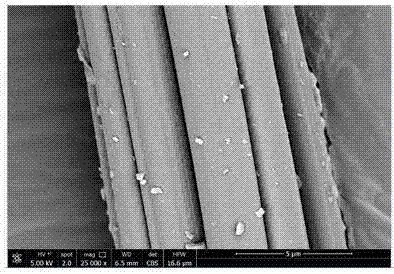

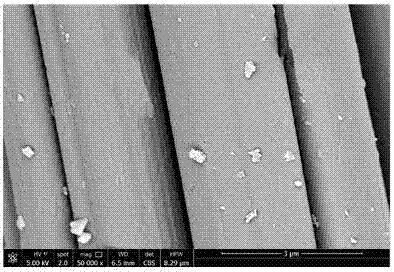

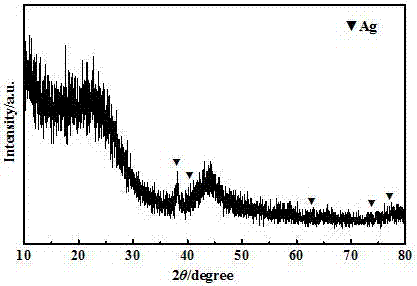

[0060] Weigh 4.3752g of silver acetate and add it to 120ml of deionized water, and stir magnetically for 35min to obtain a silver source solution with a mass concentration of 3%. Select polyacrylonitrile-based activated carbon fibers (PAN-ACF, single filament diameter 8-10μm, Nantong Senyou carbon Fiber Limited) 4g, cut into 5cm 2 / piece, dipped into the silver source solution, fully stirred by magnetic force at room temperature for 2 hours, and the rotation speed was 500rpm.

[0061] (2) Reduction of silver

[0062] The activated carbon fibers obtained by the above impregnation are put into a vacuum drying oven, dried at 80°C, then placed in 70ml of acetone, placed in a water bath, heated at 80°C, and magnetically stirred for 12 minutes at the same time. The stirring speed is 1000rpm; Dissolve 0.1964g of lauric acid in 20ml of deionized water, dissolve 0.1163g of stearic acid in 10ml of deionized water, dissolve 0.1782g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com