Functionalized oil-soluble ionic liquid and preparing method and application thereof

An ionic liquid and oil-soluble technology, applied in chemical instruments and methods, carboxylate preparation, sulfonate preparation, etc., can solve the problems of high preparation cost, restriction of industrial application, poor compatibility of lubricating oil, etc., and achieve high load capacity ability, excellent solubility, excellent anti-friction and anti-wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

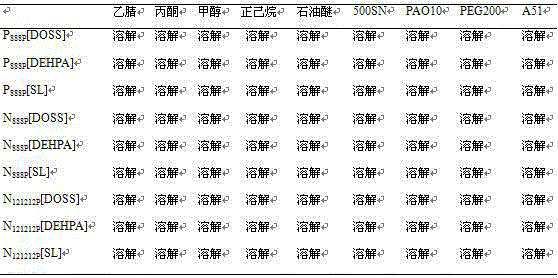

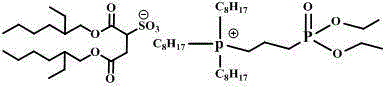

[0054] Example 1 [P 888P [DOSS] Synthesis of Ionic Liquids

[0055]

[0056] Add 37.06 grams of n-trioctylphosphine and 26.0 grams of 3-bromopropyl diethyl phosphate into a 250 mL three-necked flask, and add 100 mL of acetonitrile as a solvent, and react at 70° C. for 8 hours under the protection of an inert gas. After the reaction, the solvent was removed by spinning to obtain 60 grams of bright yellow oily viscous liquid, which was denoted as P 888P Br, 88% yield. Add 49 g of P to a 250 mL round bottom flask 888P Br, 23g 2-sulfonic acid succinate bis (2-ethyl) hexyl sodium salt, and add absolute ethanol to dissolve completely, and the solution was fully stirred for 8 hours at 50°C. After the reaction was completed, 80 ml of dichloromethane was added to dissolve, washed with distilled water, dried with anhydrous sodium sulfate, and finally the solvent was evaporated under reduced pressure to obtain 52 g of light yellow transparent oily liquid with a yield of 90%. 1 HN...

Embodiment 2

[0057] Example 2 [P 888P [DEHPA] Synthesis of Ionic Liquids

[0058]

[0059] Add 37.06 grams of n-trioctylphosphine and 26.0 grams of 3-bromopropyl diethyl phosphate into a 250 mL three-necked flask, and add 100 mL of acetonitrile as a solvent, and react at 70° C. for 8 hours under the protection of an inert gas. After the reaction, the solvent was removed by spinning to obtain 60 grams of bright yellow oily viscous liquid, which was denoted as P 888P Br, 88% yield. Add 49 g of P to a 250 mL round bottom flask 888P Br, 8.61 grams of sodium di-isooctyl phosphate, and add an appropriate amount of absolute ethanol to dissolve completely, and the solution was fully stirred at 50 ° C for 8 hours. After the reaction was completed, 80 ml of dichloromethane was added to dissolve, washed with distilled water, dried with anhydrous sodium sulfate, and finally the solvent was distilled off under reduced pressure to obtain 51 g of light yellow transparent oily liquid with a yield of...

Embodiment 3

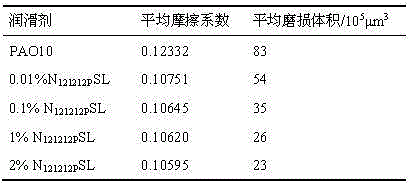

[0060] Example 3 [N 888P [SL] Synthesis of Ionic Liquids

[0061]

[0062] 37.06 grams of n-trioctylamine and 26.0 grams of 3-bromopropyl diethyl phosphate were added to a 250 mL three-necked flask, and 100 mL of acetonitrile was added as a solvent, and the reaction was carried out at 70° C. under the protection of an inert gas for 8 hours. After the reaction, the solvent was removed by spinning to obtain 60 grams of bright yellow oily viscous liquid, which was denoted as P 888P Br, 88% yield. Add 49 g of P to a 250 mL round bottom flask 888P Br, sodium laurate 22.2g, and add an appropriate amount of dehydrated alcohol to dissolve completely, and the solution was fully stirred for 8 hours at 50°C. After the reaction was completed, 80 ml of dichloromethane was added to dissolve, washed with distilled water, dried with anhydrous sodium sulfate, and finally the solvent was distilled off under reduced pressure to obtain 51 g of light yellow transparent oily liquid with a yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com