Photosensitive resin composition and method for the formation of a resin pattern using the composition

A technology of photosensitive resin and composition, which is applied in the fields of signage, formation of resin graphics, etc., can solve the problem of high product cost and achieve the effect of strong bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

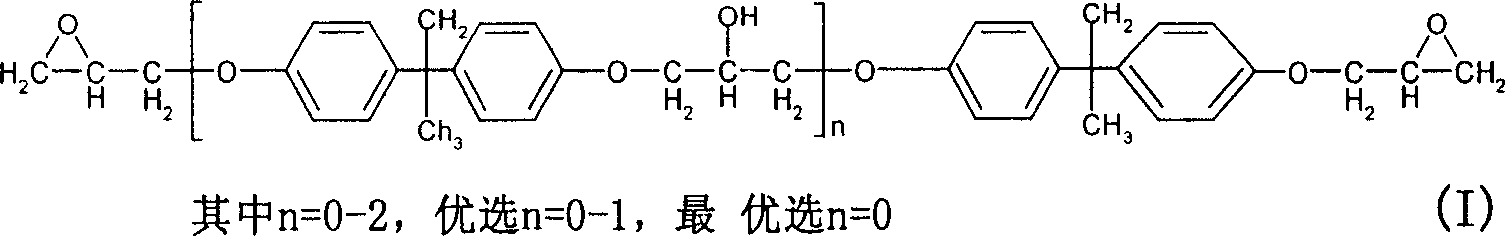

Method used

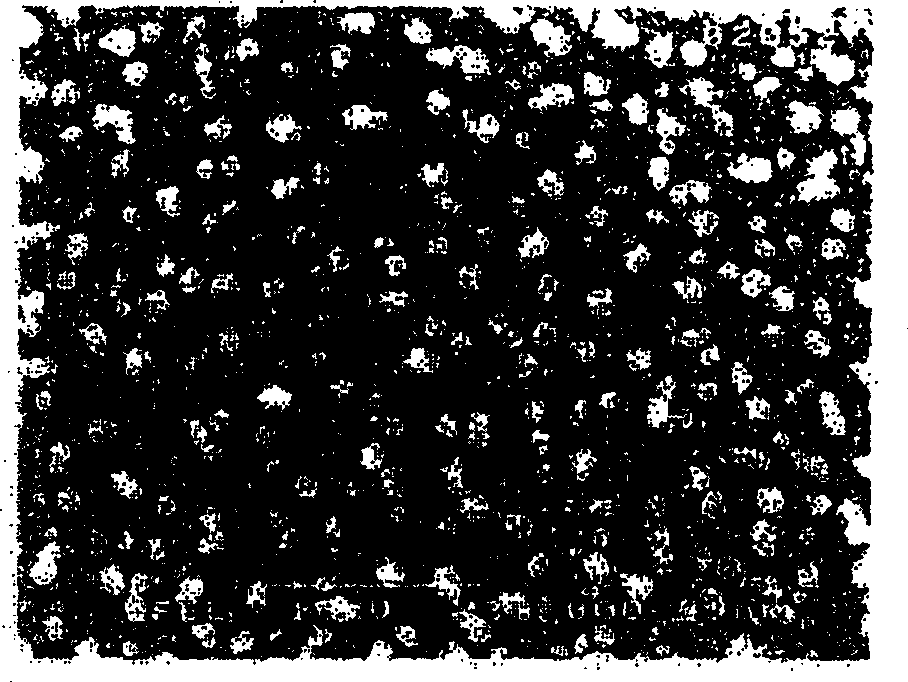

Image

Examples

Embodiment 1-9

[0107] In Examples 1-9, metal-resin composites were prepared according to the ingredients listed in Table 1. In Examples 1, 2 and 3, step 9 was carried out according to the method described above. In Examples 4-6 (comparative examples), step 9 was omitted, and step 10 was performed after step 8. In Examples 7-9, instead of Step 9, the surface of the resin pattern was physically polished using a non-woven fabric (trade name: Scotchbright, 3MCo.). In the etching process, a surface layer with a thickness of 0.5 μm was removed. In Examples 1-9, the dark red oily palladium resinate is used as the catalyst precursor. The palladium resinate contains palladium neooctoate with 8 carbon atoms, and its decomposition temperature is 200.1°C. The palladium content in the catalyst precursor was 23 wt%.

[0108] Example

Embodiment 2

[0109] In Examples 2, 3, 8 and 9, nickel deposition on the resin pattern was observed, showing the effectiveness of the method of the present invention in forming metal-resin composites.

[0110] However, on the other hand, when the plasma etching step, Step 9, was omitted, in the results obtained in Examples 4-6 (Comparative Examples), no nickel deposition was observed on the surface of the resin pattern. Therefore, activation treatment of the resin pattern or catalyst exposure treatment, such as surface etching, is necessary.

[0111] In addition, when the plasma etching treatment was replaced by wet etching treatment using sodium permanganate solution, or physical polishing treatment using gravimetric wave (data not shown in Examples 1-9), nickel was not observed on the surface of the resin pattern. deposition. This result shows that the exposure treatment of the catalyst on the surface of the resin pattern is necessary for the method of the present invention.

[0112] In...

Embodiment 10-18

[0114] In Examples 10-18, nickel deposition was studied using various catalyst precursors, see Table 2. The temperature of step 8 listed in the table is the decomposition temperature of the catalyst precursor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com