Method for patterning carbon nanotube coating and carbon nanotube wiring

a technology of carbon nanotubes and wiring lines, which is applied in the manufacture of electrode systems, nanoinformatics, electric discharge tubes/lamps, etc., can solve the problems of forming a layer that practically blocks light, the wiring lines formed by the above methods are not well-received, and the installation and maintenance of such instruments are expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

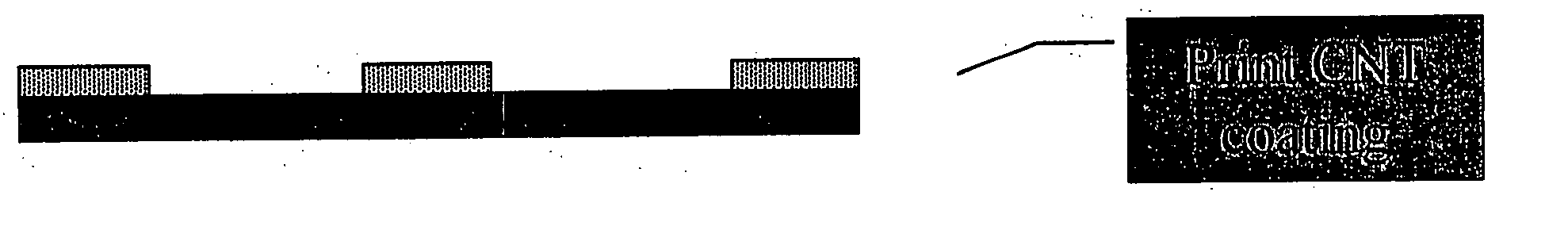

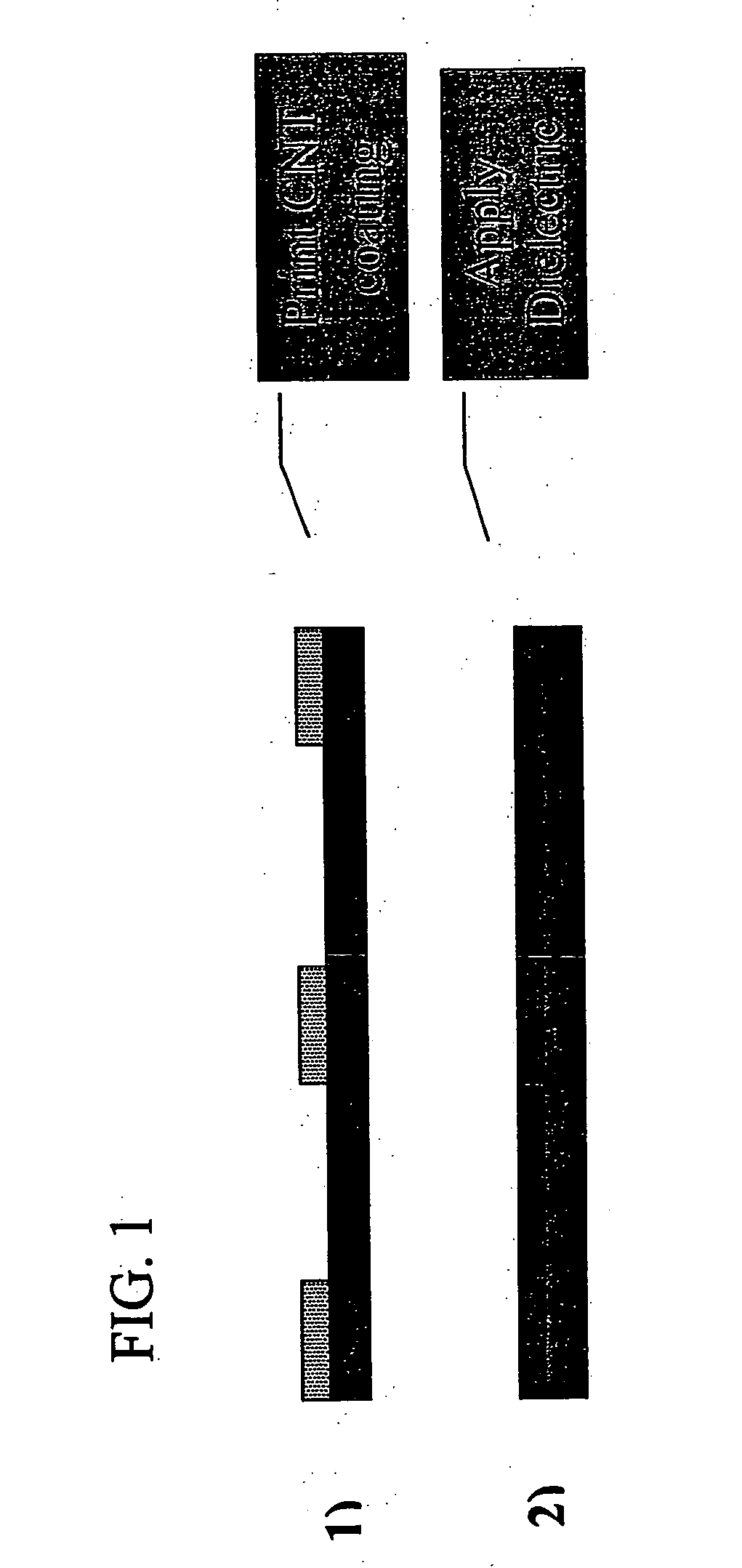

[0042] First, as purchased SWNTs are purified by process steps including acid reflex, water rinsing, centrifuge and microfiltration. Then, the purified SWNTs are mixed into a solution of isopropyl alcohol (IPA) and water to form a carbon nanotube coating solution. The SWNT solids content is in the range of 10 to 100 ppm by weight. The weight ratio of IPA to water is in the range of 1:3 to 3:1, depending on the drying rate desired for the coating. Once a reasonably stable dispersion has been achieved, the viscosity of the SWNT dispersion is increased by adding a sufficient amount of a polyacrylic acid, a viscosity modifying agent (Acrysol ASE 75, available from Rohm & Haas), to provide a coating composition having a viscosity suitable for gravure coating, (e.g., approximately 1000 cP). The carbon nanotube coating solution is printed onto a clear plastic film (e.g., polyethersulfone) using a patterned gravure roll. The IPA / water and viscosity modifier are then removed by heating, leav...

example 2

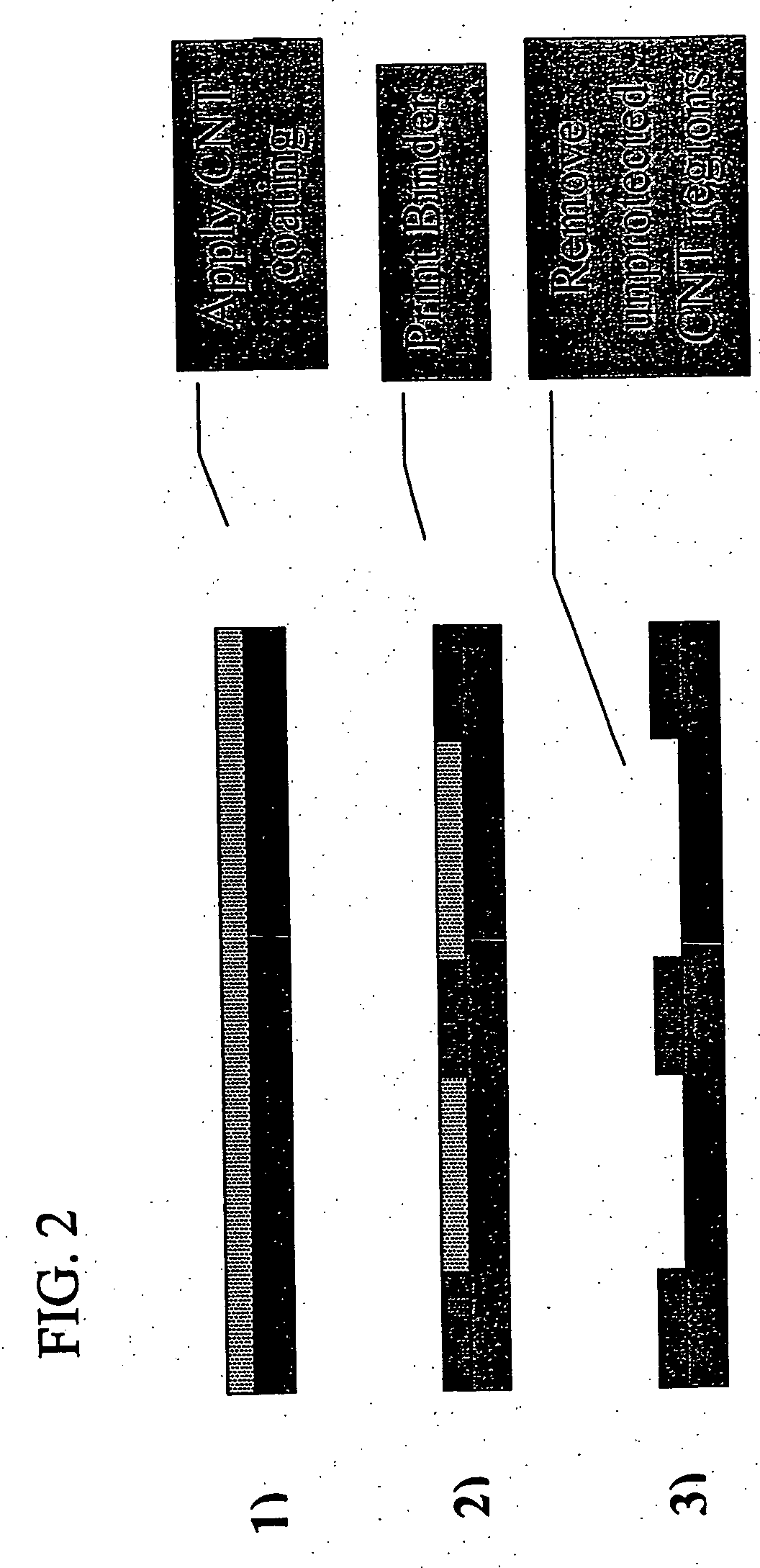

[0043] First, as purchased SWNTs are purified by process steps including acid reflex, water rinsing, centrifuge and microfiltration. Then, the purified SWNTs are mixed into a solution of isopropyl alcohol (IPA) and water to form a carbon nanotube coating solution. The SWNT solids content is in the range of 10 to 100 ppm by weight. The weight ratio of IPA to water is in the range of 1:3 to 3:1, depending on the drying rate desired for the coating. The SWNT coating is applied to a clear plastic film (e.g., polyester film such as PET or PEN film from Dupont Teijin Films) using an atomized spraying technique. The substrate is heated to 60° C. to increase drying rate of the IPA / water. A sufficient thickness of the consolidated carbon nanotubes is applied to achieve the desired electrical resistance (e.g., 500 ohms / square). Then, a binder coating such as acrylic resin dissolved in ethyl acetate is printed using a screen printing technique. The binder coating permeates selected regions of ...

example 3

[0044] First, as purchased SWNTs are purified by process steps including acid reflex, water rinsing, centrifuge and microfiltration Then, the purified SWNTs are mixed into a solution of isopropyl alcohol (IPA) and water to form a carbon nanotube coating solution. The SWNT solids content is in the range of 10 to 100 ppm by weight. The weight ratio of IPA to water is in the range of 1:3 to 3:1, depending on the drying rate desired for the coating. The SWNT coating is applied to a glass substrate using an atomized spraying technique. The substrate is heated to 60° C. to increase drying rate of the IPA / water. A sufficient thickness of consolidated carbon nanotubes is applied to achieve the desired electrical resistance (e.g., 500 ohms / square). Then, a photo definable polyimide binder such as HD-4000 Series from HD Microsystems is applied to the consolidated carbon nanotube film using a Meyer rod coating technique. The photoresist permeates the carbon nanotube film. A predetermined wirin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| light transmittance | aaaaa | aaaaa |

| total light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com