Method for preparing high-temperature oxidation-resistant coating on niobium tungsten alloy

A high-temperature anti-oxidation and alloying technology, applied in the direction of metal material coating technology, coating, metal processing equipment, etc., can solve the problems of coating peeling, coating brittle fracture, large coating powder gap, etc., to improve the density The effect of sex, dense structure and tight organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

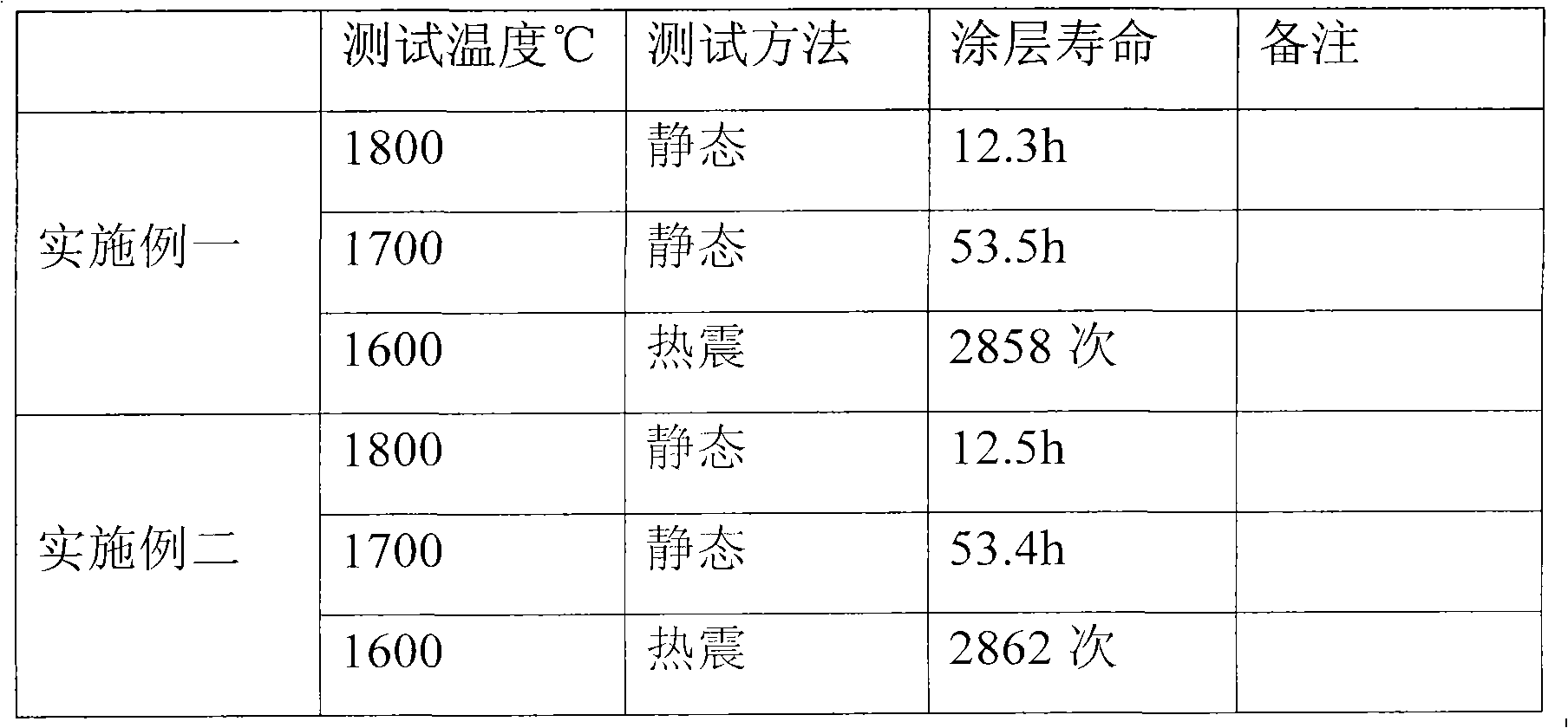

Examples

Embodiment 1

[0028] The first step: using liquid nitrogen low-temperature ball milling technology to nano-process Mo and Si powders with a particle size of 28-48 microns to prepare nano-powders with high thermal stability, together with other powders MoSi with a particle size of 28-48 microns 2 , W, HfO 2 , Y are mixed according to the ratio in the patent application CN1948218, and then processed by liquid nitrogen low-temperature ball milling for 15-20 hours for nano-processing.

[0029] Step 2: Fix the sample of niobium-tungsten alloy (Nb521) on the frame, add the Si nano-powder made by liquid nitrogen low-temperature ball milling into the powder feeder, adjust the working air pressure at the inlet of the spray gun nozzle to 3Mpa, and the temperature to 450 ℃, the powder feeding speed is 20 g / min, the working gas is heated to 550 ℃, and the pressure is increased to 3.5Mpa. The nozzle of the spray gun is selected with a throat diameter of 2.7mm and an outlet diameter of 8.6mm. Nitrogen ...

Embodiment 2

[0034] The first step: using liquid nitrogen low-temperature ball milling technology to nano-process Mo and Si powders with a particle size of 28-48 microns to prepare nano-powders with high thermal stability, together with other powders MoSi with a particle size of 28-48 microns 2 , W, HfO 2 , Y are mixed according to the ratio in the patent application CN1948218, and then processed by liquid nitrogen low-temperature ball milling for 15-20 hours for nano-processing.

[0035] Step 2: Fix the niobium-tungsten alloy (Nb521) sample on the frame, add the Mo nano powder obtained by liquid nitrogen low-temperature ball milling into the powder feeder, adjust the working air pressure at the inlet of the spray gun nozzle to 3Mpa, and the temperature to 450 ℃, the powder feeding speed is 20 g / min, the working gas is heated to 550 ℃, and the pressure is increased to 3.5Mpa. The nozzle adopts a throat diameter of 2.7mm and an outlet diameter of 8.6mm. use N 2 For working gas, N 2 The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com