Photosensitive electrically conductive paste and electrode pattern

A conductive paste, electrode pattern technology, applied in the direction of lithography/pattern, pattern and lithography, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of difficult to achieve high fineness of conductor patterns and low thin film. issues of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

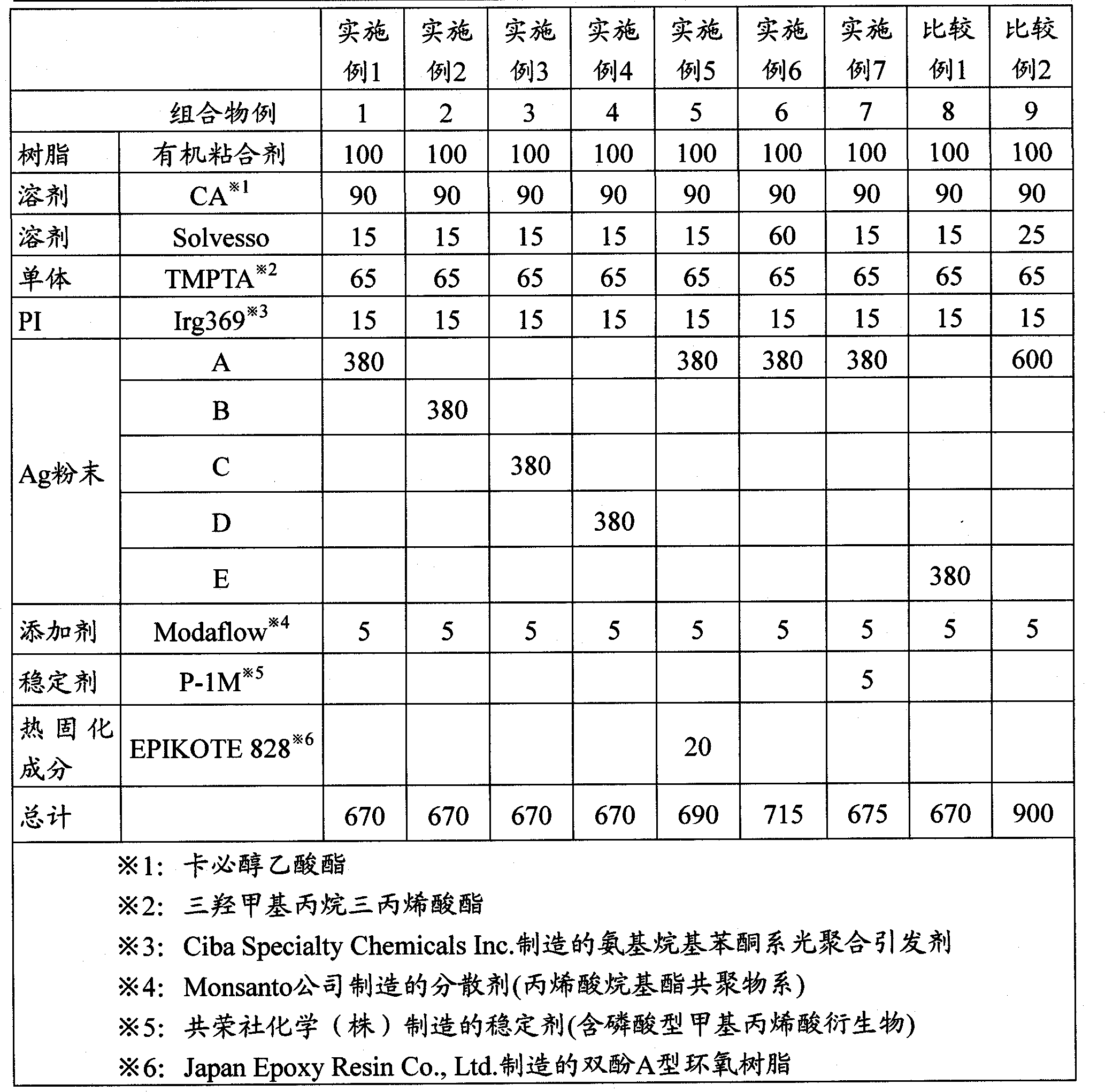

Method used

Image

Examples

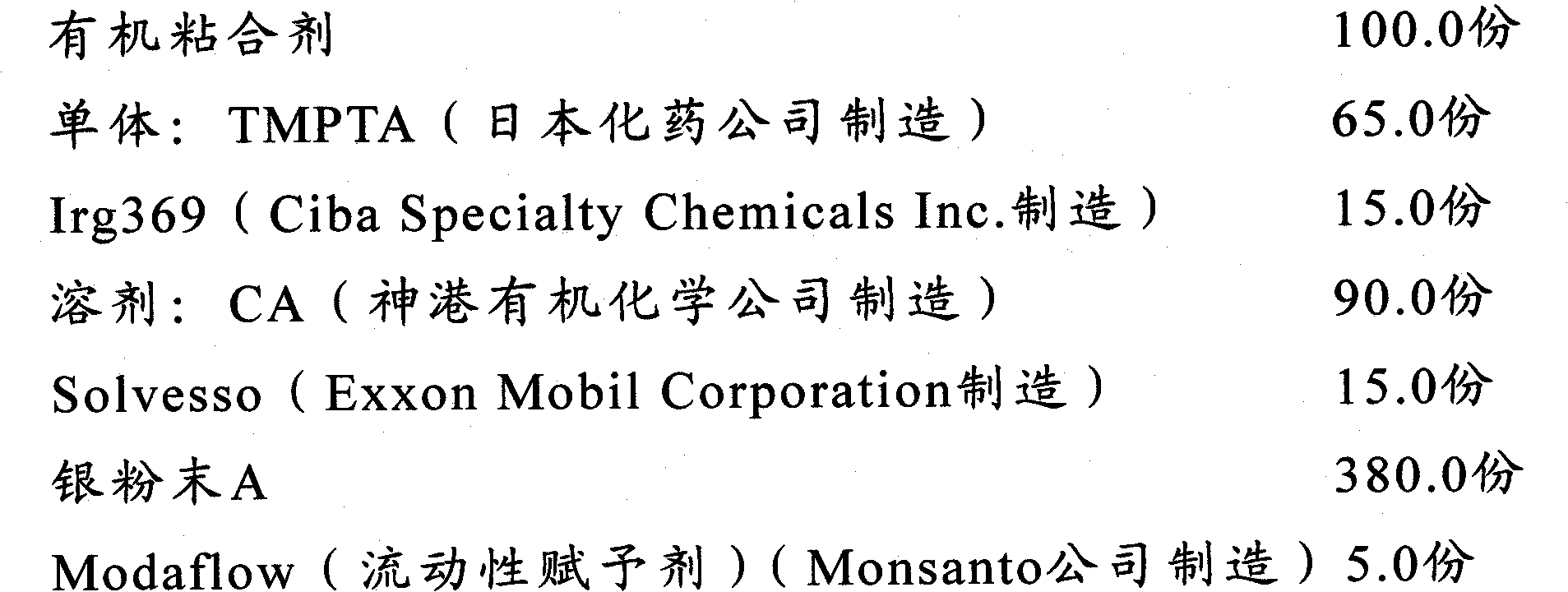

Embodiment 1

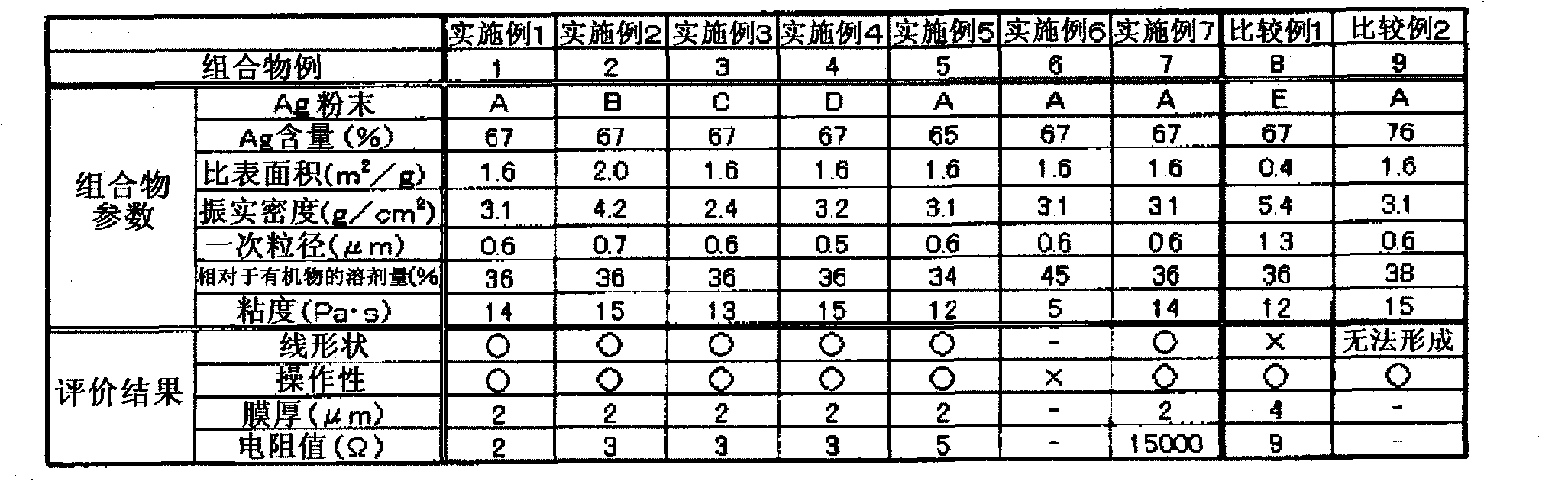

[0109] Good evaluation results were obtained in Examples 1 to 5. In addition, in Example 6, since the amount of the solvent relative to the organic matter is larger than that in Example 1, it can be seen that the viscosity is lowered and the workability is deteriorated under the coating conditions. In Example 7, although the resistance value increased due to the addition of phosphate ester, good evaluation results were obtained for the line shape, handleability, and film thickness.

[0110] On the other hand, in Comparative Example 1, since the silver powder having a large primary particle size was used, the wire shape was poor, and the resistance value also increased. In addition, the film thickness cannot be reduced. In addition, in Comparative Example 2, since the silver powder was used in a predetermined amount or more, the electrode pattern itself could not be formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com