Liquid crystal display device and method for manufacturing same

一种液晶显示装置、法线方向的技术,应用在非线性光学、仪器、光学等方向,能够解决信号延迟、配线电阻变大等问题,达到良好扩大、良好区域、容易实现的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

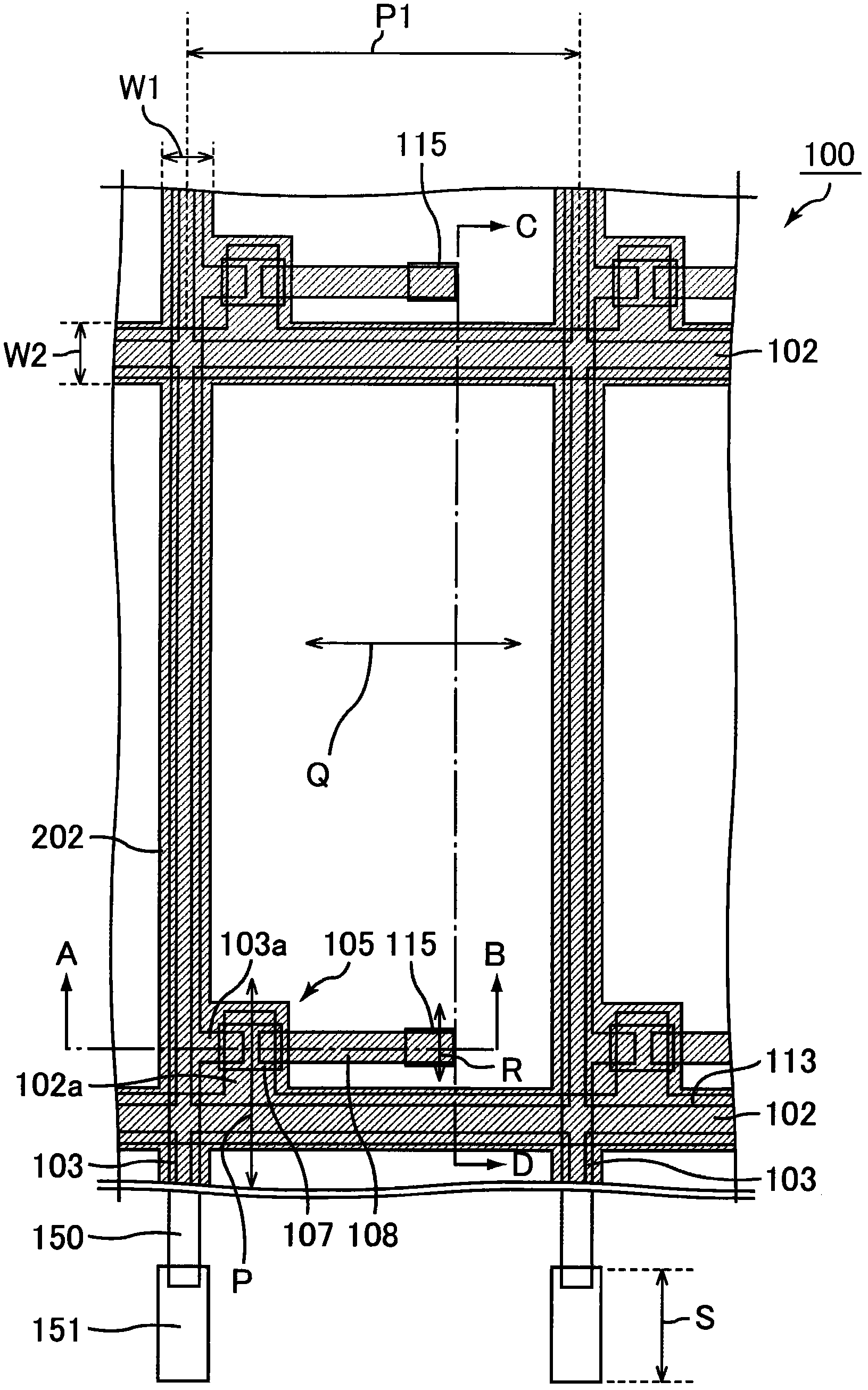

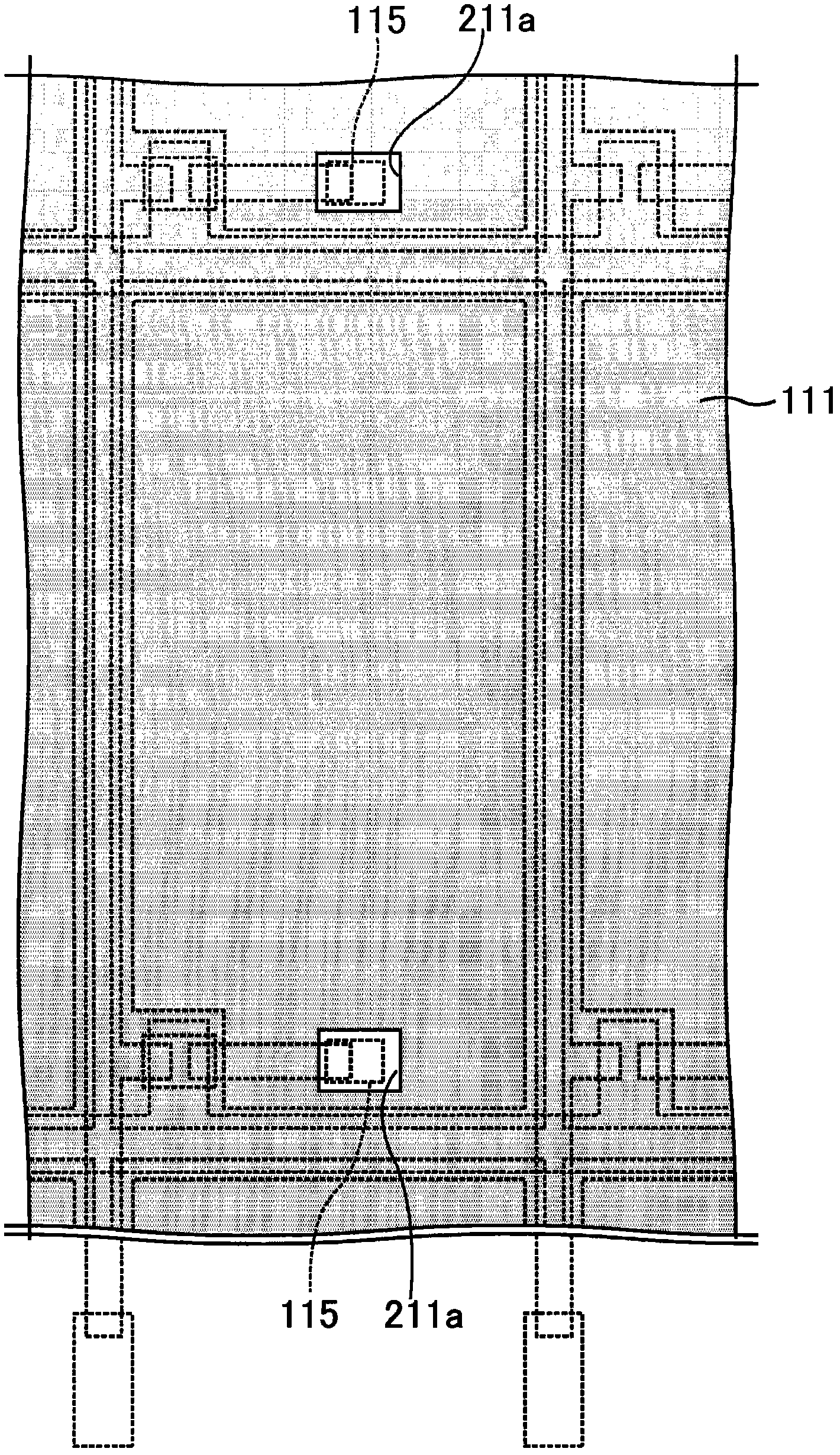

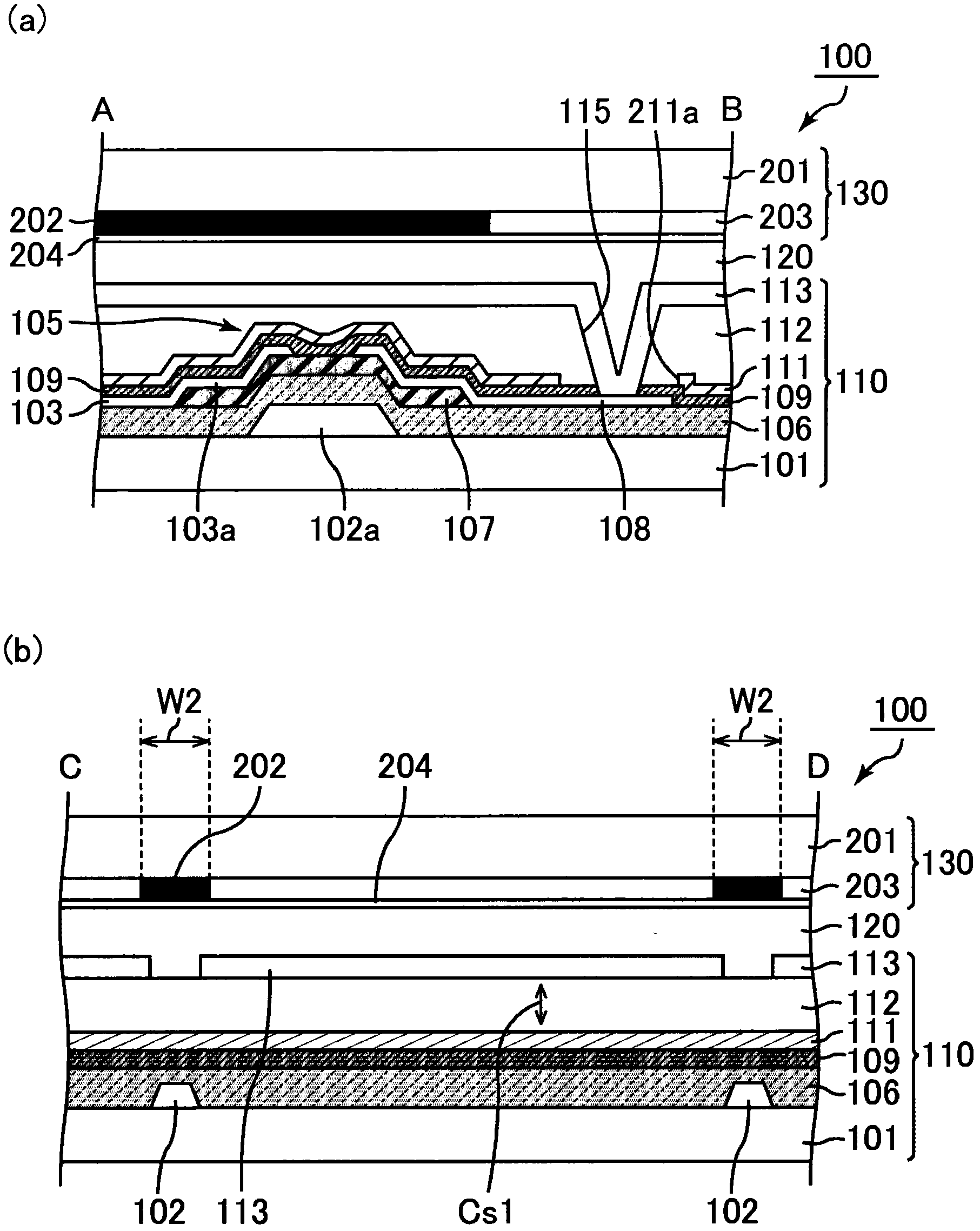

[0067] Picture 1-1 is a schematic plan view showing the configuration of a pixel of the liquid crystal display device according to Embodiment 1 of the present invention, Figure 1-2 It is a schematic plan view showing the structure of a transparent conductive film. figure 2 (a) is along Picture 1-1 A schematic cross-sectional view of the line A-B in, figure 2 (b) is along Picture 1-1 Schematic cross-sectional view of line C-D in .

[0068] exist Picture 1-1 , figure 2 In (a) and (b), the liquid crystal display device 100 includes a TFT array substrate 110 , a liquid crystal layer 120 , and a color filter (CF) substrate 130 as an opposing substrate. The TFT array substrate 110 and the CF substrate 130 are arranged facing each other with the liquid crystal layer 120 interposed therebetween.

[0069] Gate lines (scanning lines) 102 and source lines (signal lines) 103 are arranged in a grid pattern on the main surface of a support substrate 101 constituting the TFT a...

Embodiment 1

[0110] As a result of setting the pixel pitch P1 to 39 μm in the liquid crystal display device 100 of Embodiment 1, even with the same pixel size, it is comparable to a liquid crystal display device formed by a process using five normal masks (comparative implementation described later). Compared with the liquid crystal display device 500 of Embodiment 1, the aperture ratio is increased by 35%.

[0111] In the present invention, if a sufficient storage capacitance cannot be secured with the configuration of the first embodiment, the aperture ratio of the pixel will be slightly lowered. However, Cs wiring and Cs electrodes may be provided to ensure storage capacitance. Next, a configuration in which Cs wiring and / or Cs electrodes are provided will be described.

Embodiment approach 2

[0113] In this embodiment, an example in which a Cs electrode is provided in addition to the configuration of Embodiment 1 to ensure storage capacitance will be described. Components having the same configuration as those in the first embodiment described above are denoted by the same reference numerals and description thereof will be omitted.

[0114] Figure 5-1 is a schematic plan view showing the configuration of a pixel of a liquid crystal display device according to Embodiment 2 of the present invention, Figure 5-2 It is a schematic plan view showing the structure of a transparent conductive film. Figure 6 (a) is along Figure 5-1 A schematic cross-sectional view of the line A-B in, Figure 6 (b) is along Figure 5-1 The schematic cross-section of line C-D in, Figure 6 (c) is shown Figure 6 An enlarged schematic view of a part of (b).

[0115] exist Figure 5-1 In the liquid crystal display device 210, the TFT 105 is located at the lower left corner of the pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com