Gasket type measuring hole and pressure type flow control device using the measuring hole

A technology of flow measuring hole and flow measuring orifice plate, which is applied in the direction of flow control, measuring device, non-electric variable control, etc., can solve the problem of not being able to realize space saving, and achieve good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

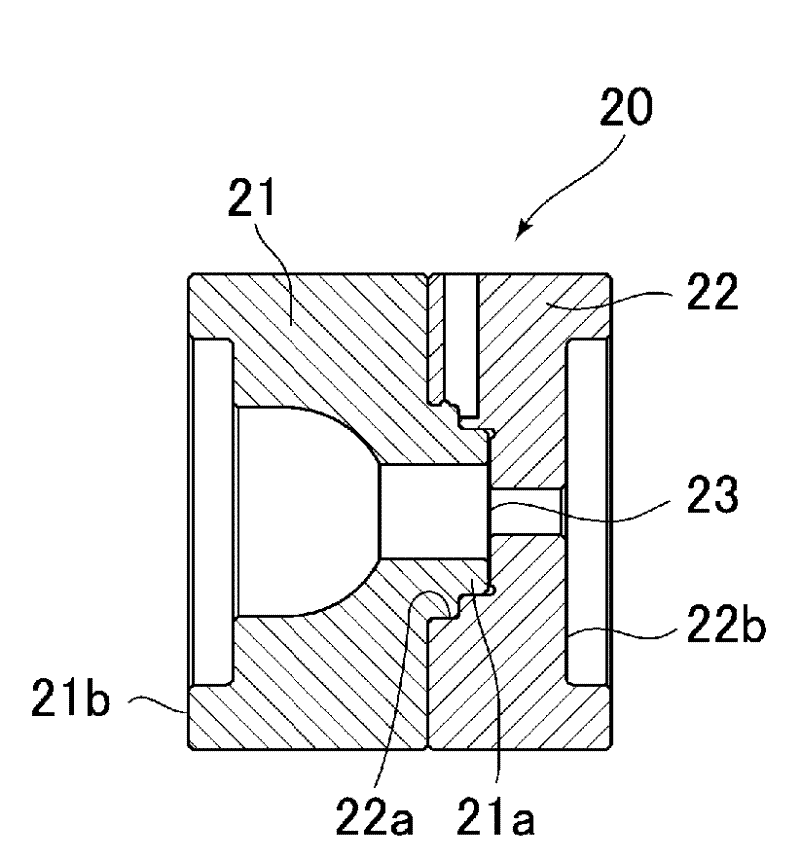

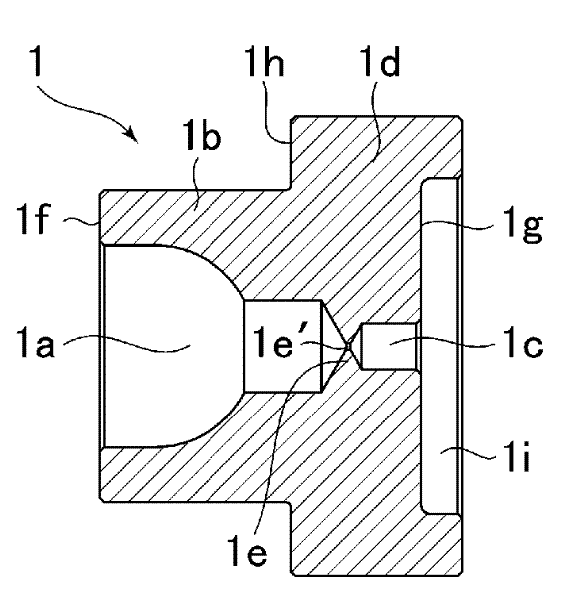

[0076] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

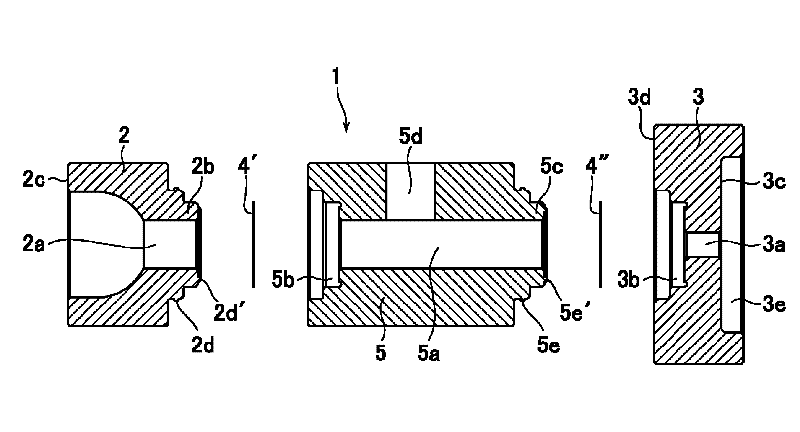

[0077] Figure 1 to Figure 4 A gasket-type flow hole 1 and a pressure-type flow control device using the flow hole according to an embodiment of the present invention are shown.

[0078] The above-mentioned gasket type flow hole 1 such as figure 1 and figure 2 As shown, the convex flow hole base 2 has a through-shaped passage 2a in the center and a protrusion 2b for fitting on the inner end surface, has a through-shaped passage 3a in the center, and has a fitting on the inner end surface. Combining the concave flow measuring hole base 3 of the concave portion 3b and the flow measuring orifice plate 4 formed with a flow measuring orifice (not shown) in the center, the convex flow measuring hole base 2 and the concave shape The flow measuring hole base 3 is combined, the flow measuring orifice plate 4 is airtightly inserted between the two measuring flow hole bases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com