Internal combustion engine control device

A technology of a control device and an internal combustion engine, which is applied in the directions of engine control, fuel injection control, electrical control, etc., can solve the problems of inability to control the inverse model torque of the internal combustion engine, and the inability of the actuator to accurately reflect the performance of the internal combustion engine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

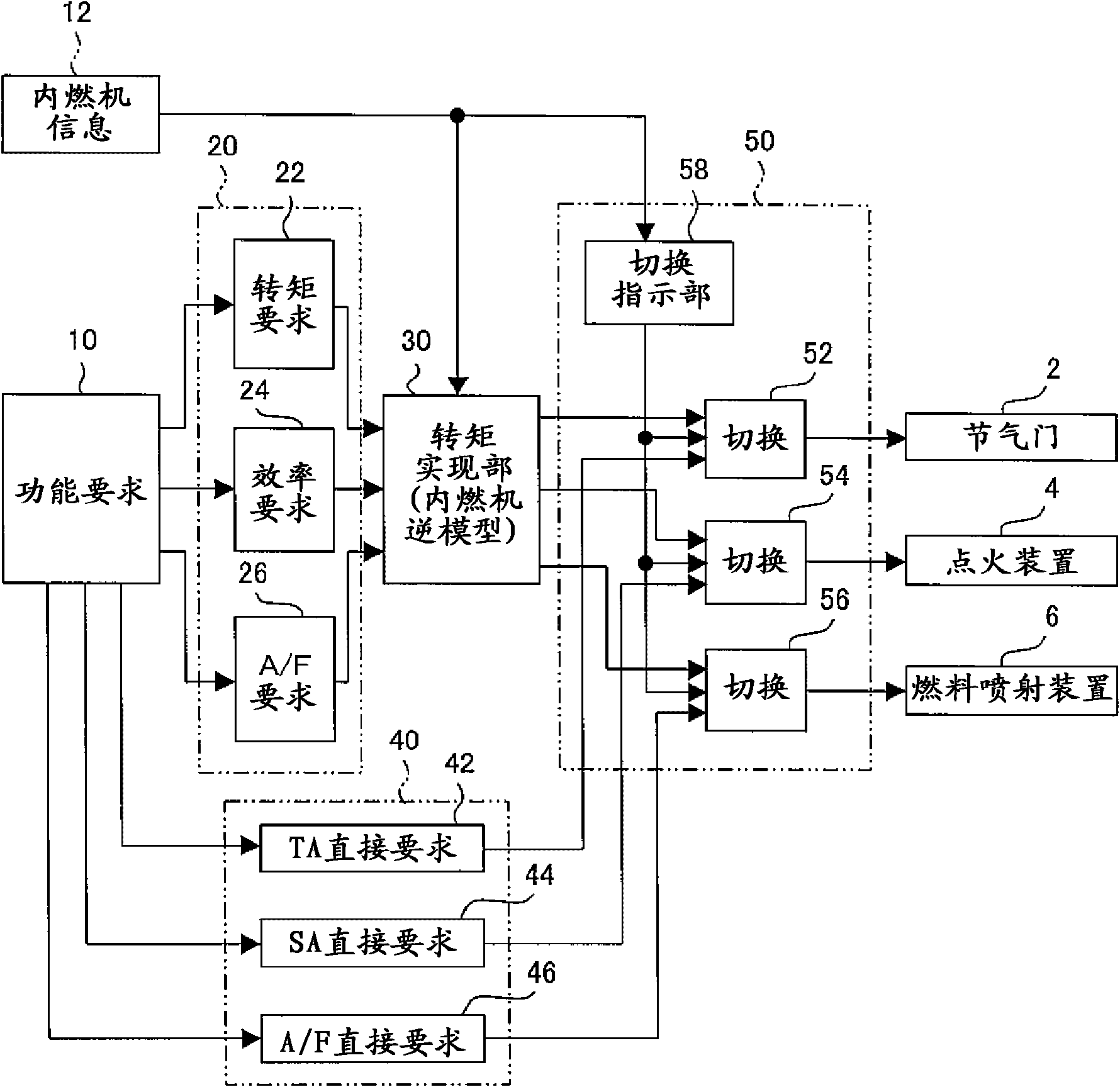

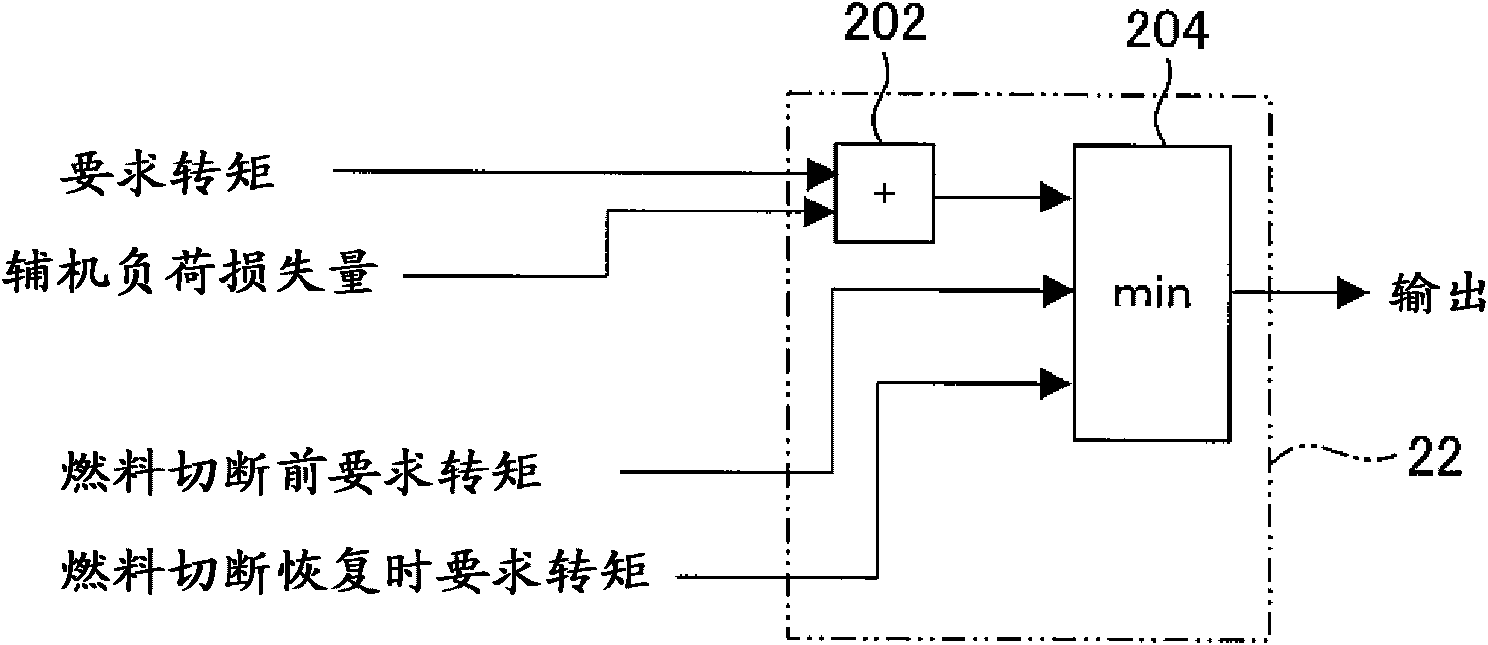

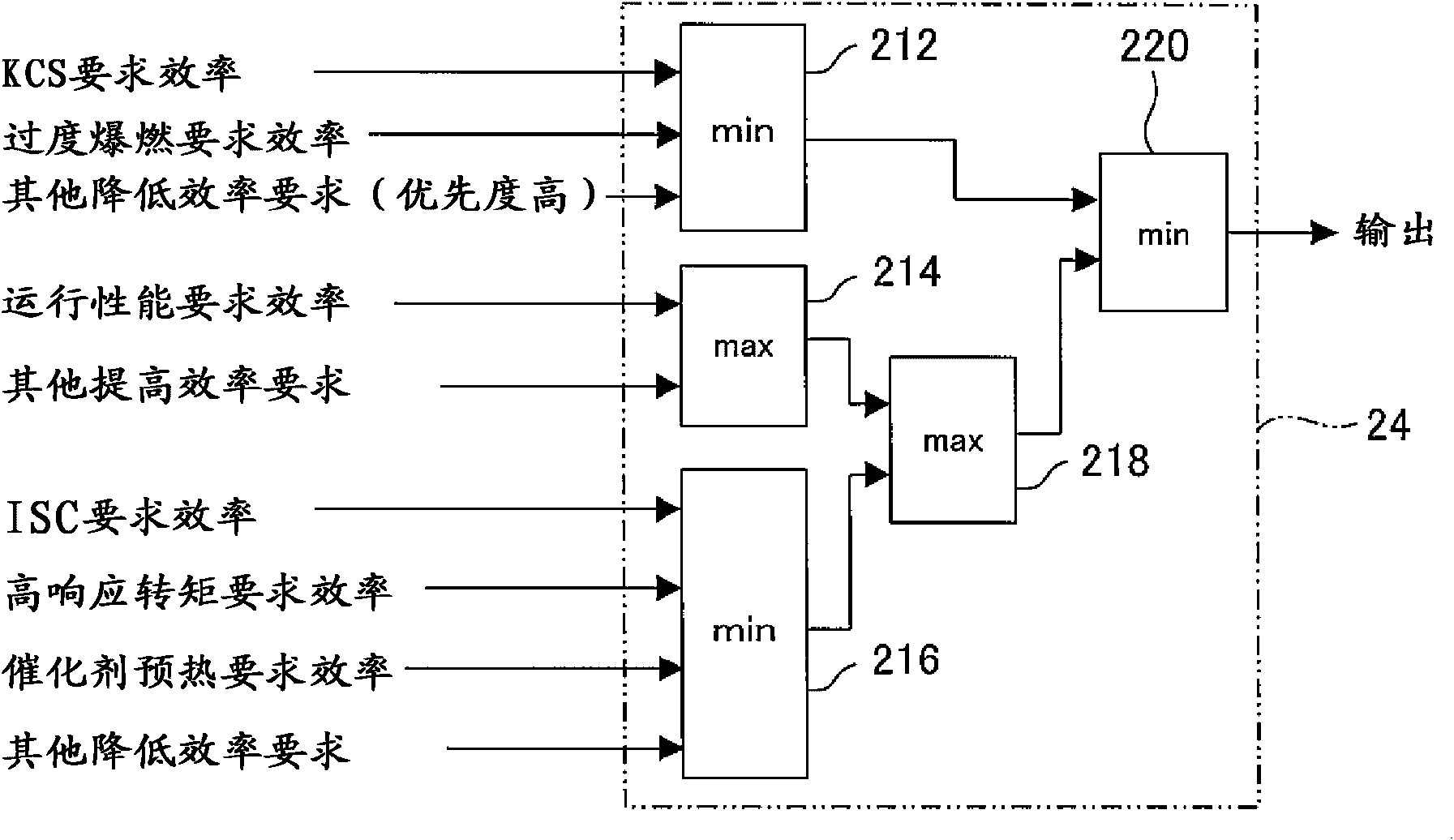

[0119] Below, use Figure 1 to Figure 4 Each figure of FIG. 1 illustrates Embodiment 1 of the present invention.

[0120] First, specifications of the internal combustion engine according to the present embodiment will be described as a premise of the present embodiment. The internal combustion engine according to the present embodiment is a spark ignition type internal combustion engine, and includes an actuator for adjusting the amount of intake air, ignition timing, and air-fuel ratio. In addition, it is an internal combustion engine that normally performs operation of homogeneous combustion, but can also perform operation of stratified combustion under limited conditions such as extremely low load. In addition, the specifications of the internal combustion engine according to this embodiment are also the same specifications as those of Embodiments 2 to 9 described later.

[0121] The control device of this embodiment is configured to use figure 1 The block diagram repre...

Embodiment approach 2

[0170] Next, use figure 1 , Figure 5 and Figure 6 Embodiment 2 of the present invention will be described.

[0171] The overall structure of the control device of this embodiment is the same as Embodiment 1, with figure 1 The block diagram representation. The difference between the control device of the present embodiment and the control device of the first embodiment lies in the function of the switching instruction unit 58 which is one element constituting the control device. Indicates the configuration of the switching instruction unit 58 according to the present embodiment is Figure 5 block diagram. Refer to the following figure 1 and Figure 5 The structure and function of the switching instructing unit 58 which is a characteristic of the present embodiment will be described.

[0172] The functional feature of the switching instructing unit 58 according to this embodiment is that it can suppress the switching of the control of the actuators 2, 4, 6 from the con...

Embodiment approach 3

[0195] Next, use figure 1 and Figure 7 Embodiment 3 of the present invention will be described.

[0196] The overall structure of the control device of this embodiment is the same as Embodiment 1, with figure 1 The block diagram representation. The difference between the control device of the present embodiment and the control device of the first embodiment lies in the function of the switching instruction unit 58 which is one element constituting the control device. Indicates the configuration of the switching instruction unit 58 according to the present embodiment is Figure 7 block diagram. Refer to the following figure 1 and Figure 7 The structure and function of the switching instructing unit 58 which is a characteristic of the present embodiment will be described.

[0197] Functional features of the switching instruction unit 58 according to the present embodiment are common to those of the switching instruction unit 58 according to the second embodiment. Howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com