Optical field frequency multiplication sweep device based on electro-optical material optical waveguide

A technology of electro-optical materials and optical waveguides, applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of low sweep frequency, high driving voltage, large device size, etc., and achieve the effect of reducing the modulation frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

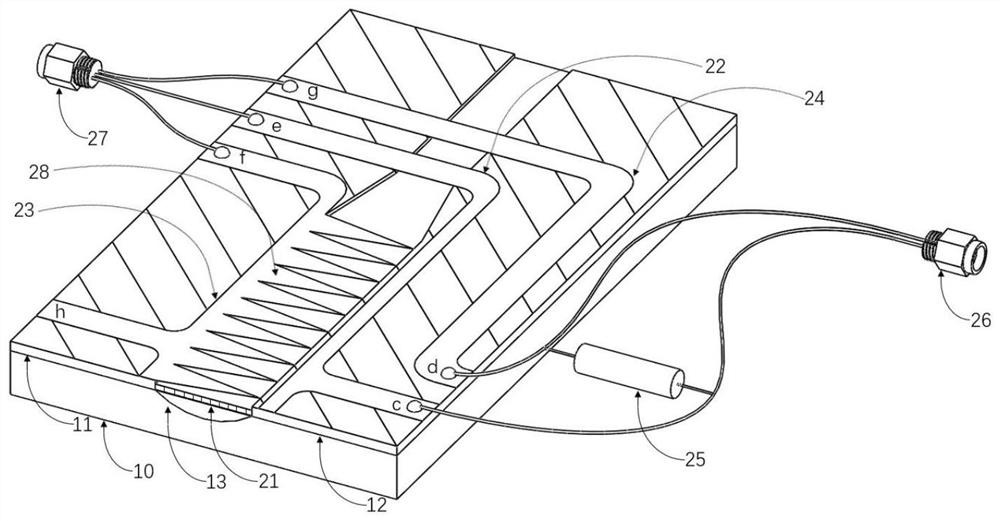

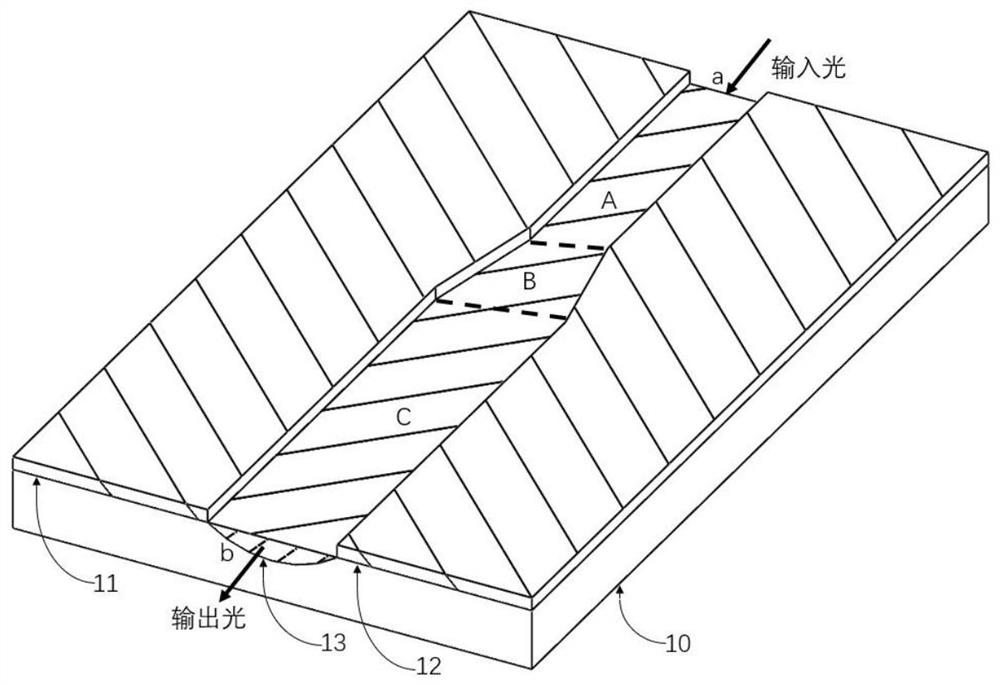

[0050] refer to figure 1 and figure 2 , the present invention provides an optical field frequency multiplication sweeper based on an electro-optic material optical waveguide, comprising a substrate 10, a first mask plate 11, a second mask plate 12, a waveguide core layer 13, and a waveguide core layer buffer layer 21. Sawtooth electrode, signal electrode 22 with double tentacles, ground electrode 23 with first double tentacles, ground electrode 24 with second double tentacles, matching resistor 25, first signal input port 26 and second signal input port 27:

[0051] The thicknesses of the first mask plate 11 and the second mask plate 12 are equal, and the first mask plate 11 and the second mask plate 12 are arranged at intervals on the substrate 10. The substrate 10, the first mask plate 12 The mask plate 11 and the second mask plate 12 form a groove-like space, the depth of the groove is the same as the thickness of the first mask plate 11 and the second mask plate 12, and th...

Embodiment 2

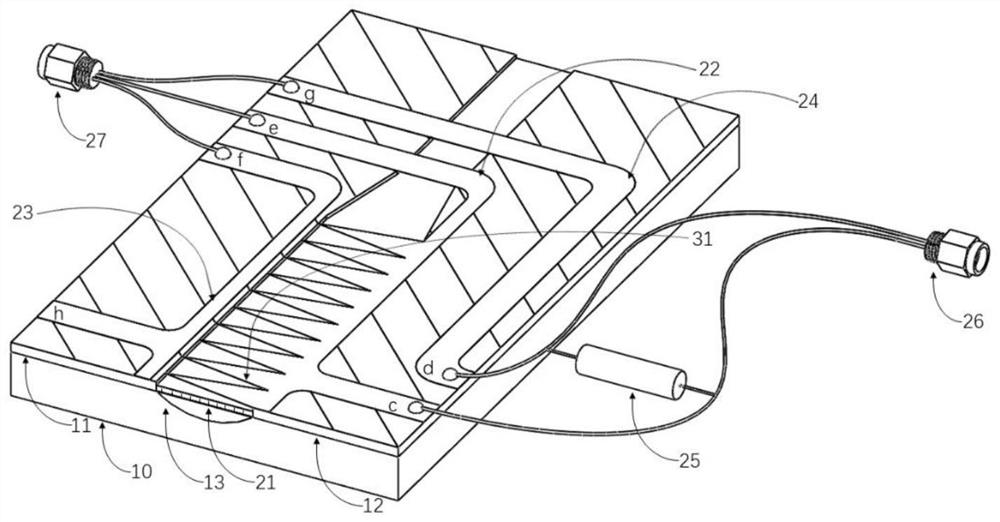

[0067] This embodiment is similar to Embodiment 1, refer to figure 2 and image 3 , is a schematic diagram of another scheme of the optical waveguide device. The difference between this embodiment and Embodiment 1 is that the bottom edge of the isosceles triangular sawtooth electrode 31 is connected to the double-antenna signal electrode 22, and the apex faces the first double-antenna ground wire electrode 23, and the height on the bottom side is equal to the width of the beam output area C of the waveguide core layer. The vertex of the isosceles triangular sawtooth electrode 31 is not in contact with the first double-stent ground electrode 22 , and its vertex is about 5 μm away from the first double-stent ground electrode 22 .

[0068] In the optical waveguide of the second embodiment, the refractive index of the waveguide core layer 13 is changed into a phased array by connecting the sawtooth electrode 31 of the double-tentacle signal electrode 22, thereby improving the de...

Embodiment 3

[0070] Such as Figure 4 Shown is a schematic diagram of an electro-optic and thermo-optic dual-effect mode wiggler experimental device, a laser 41, an input optical fiber 42, an optical waveguide 43, a signal source 44, a lens 45 and a mode monitor 46, wherein the input optical fiber 42 includes a single-mode optical fiber or a panda Polarization-maintaining fiber, preferably, Panda polarization-maintaining fiber is used as the input fiber 52 . The light beam to be adjusted outputted by the laser 41 is exported through the connection input optical fiber 42 . The tail end of the input optical fiber 42 is aligned with the center of the input end face a of the optical waveguide, so that the light beam to be modulated is coupled into the optical waveguide 43 . The signal input port of the optical waveguide is connected to the signal source 44, so that the light beam in the optical waveguide is modulated. If the signal source 44 is connected to the first signal input port on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com