Method for manufacturing quadri-junction GaInP/GaAs/InGaAs/Ge solar cells

A technology of a solar cell and a manufacturing method, applied in the field of solar photovoltaic, can solve the problems of increasing the difficulty of the battery process, decreasing the battery efficiency, high battery cost, etc., and achieving the effects of improving the photoelectric conversion efficiency, reducing the thermal energy loss, and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the specific embodiments of the present invention will be described in detail below:

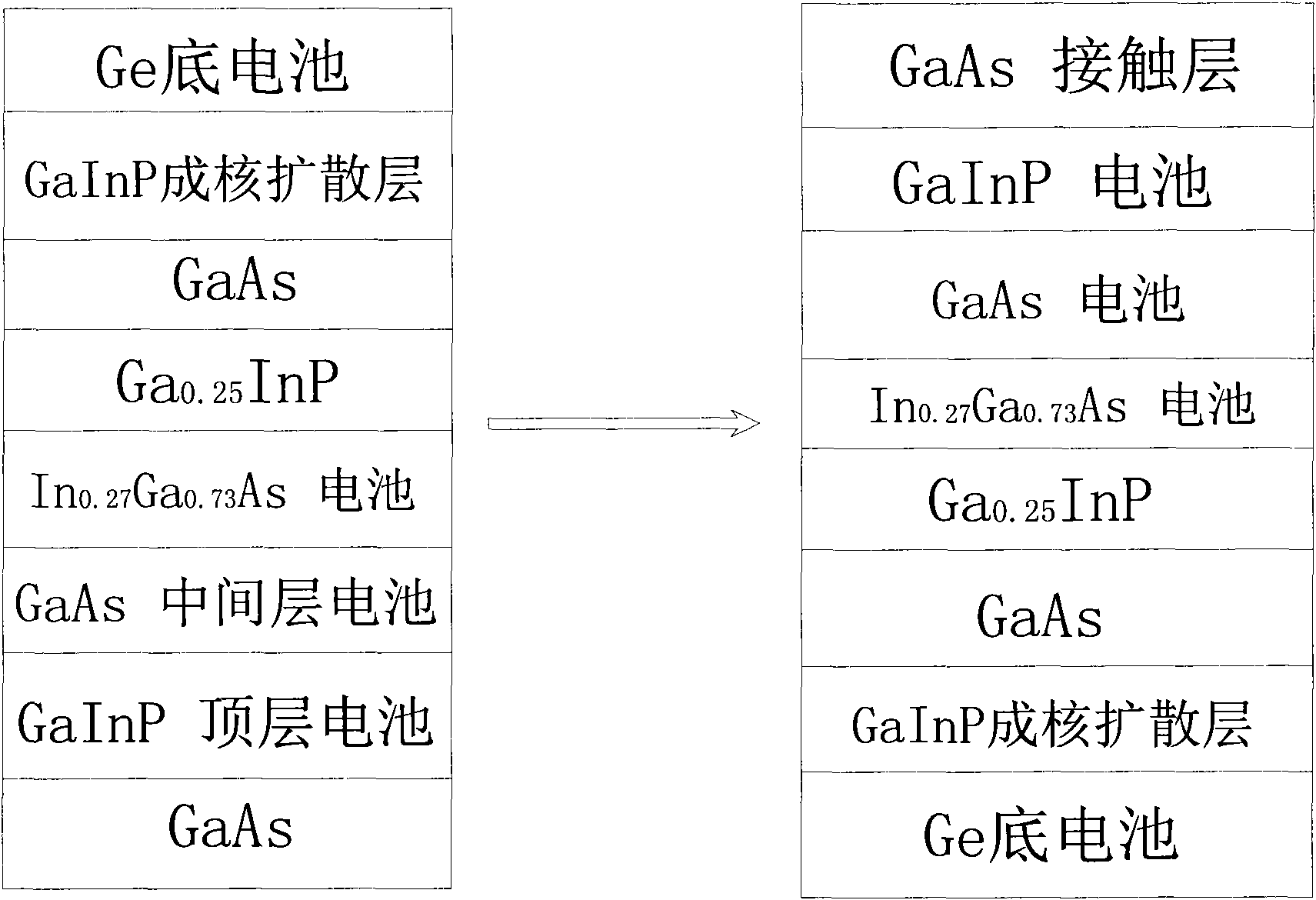

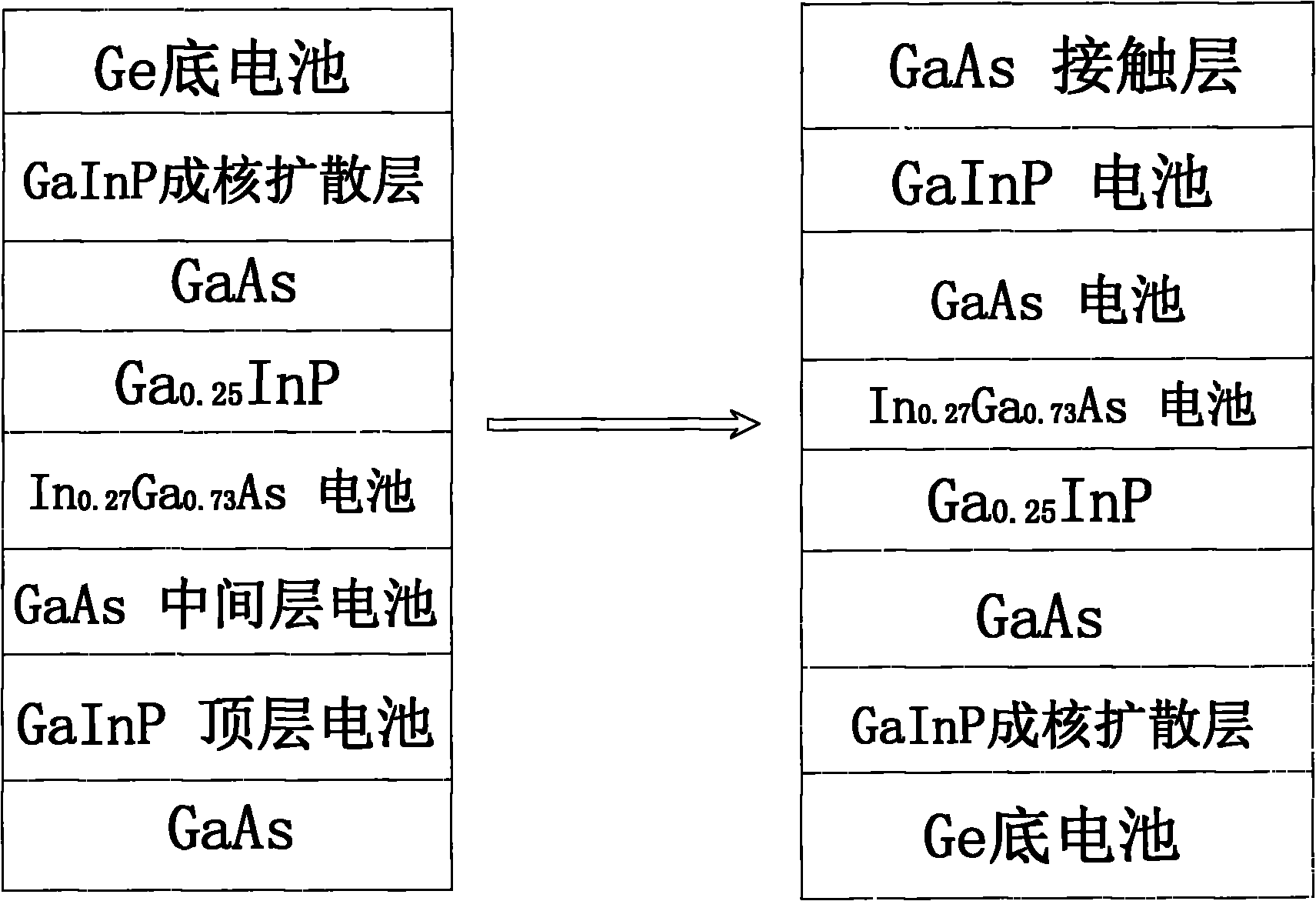

[0021] 1) Cell growth before bonding

[0022] Such as figure 1 As shown, it is a schematic diagram of the cell structure conversion before and after bonding of the triple-junction GaInP / GaAs / InGaAs solar cell and the single-junction Ge solar cell used in the present invention. It can be clearly seen from the attached figure that the triple-junction cell adopts an inverted growth method, and first grows Ga on the GaAs substrate. 0.51 InP, then GaAs, and finally In 0.27 Ga 0.73 As. The advantage of this is that there is only one interface lattice mismatch. Compared with the direct growth of InGaAs on GaAs, an interface mismatch will be added, that is, between InGaAs and GaAs substrate and between the GaAs battery in the middle. How to effectively tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com