High-concentration photovoltaic power generation heating supply system

A high-power concentration, photovoltaic power generation technology, applied in photovoltaic power generation, photovoltaic thermoelectric hybrid power generation, photovoltaic modules, etc., can solve the heat exchange effect that is difficult to achieve instantaneous cooling, cannot make full use of solar energy resources, and is difficult to effectively reduce battery temperature, etc. problems, to facilitate installation and component design, enhance heat exchange and cooling effect, and solve the problem of high heat flux density and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be further described through examples below in conjunction with the accompanying drawings.

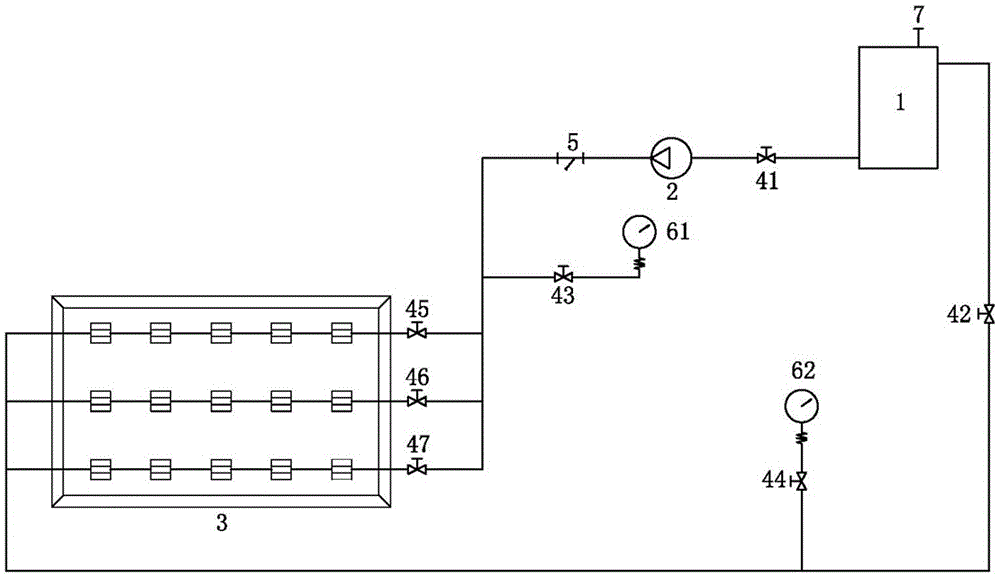

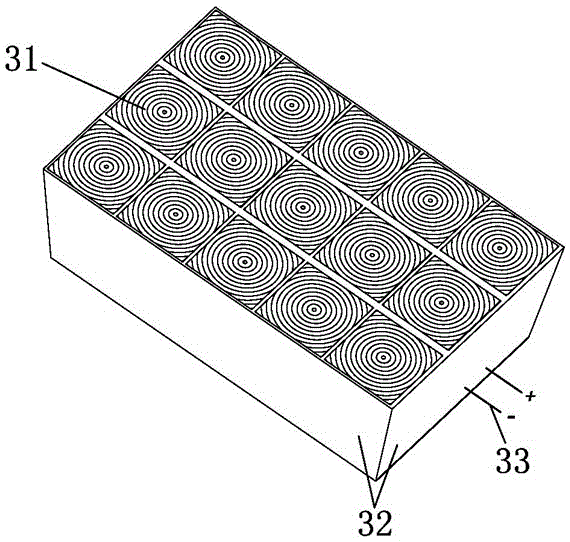

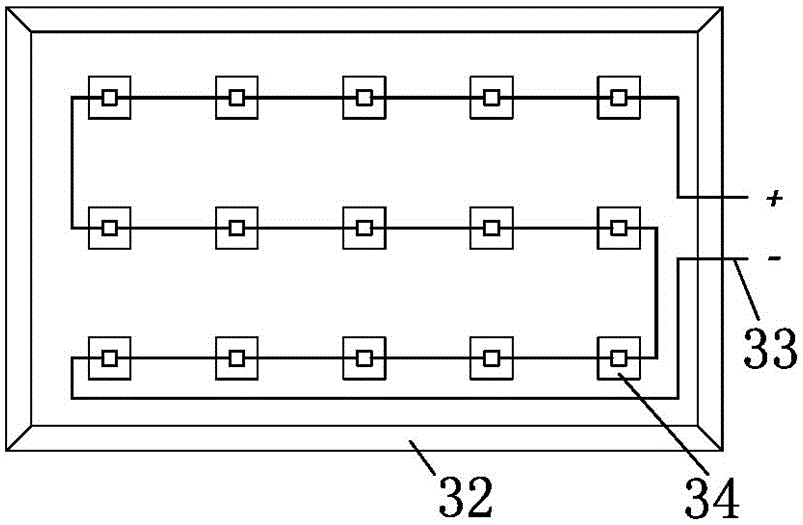

[0032] see figure 1 A high-power concentrated photovoltaic power generation heating system includes a water tank 1, a water pump 2, and a high-power concentrated photovoltaic photothermal mechanism. see figure 1 and figure 2 , the high-power concentrating photovoltaic photothermal mechanism is composed of three groups of parallel photovoltaic photothermal modules 3; each group of photovoltaic photothermal modules 3 includes five series connected photovoltaic photothermal mechanisms; each photovoltaic photothermal mechanism is composed of a Fresnel lens 31 and Photovoltaic receiving mechanism 34 is formed. see Figure 4 and Figure 5 The photovoltaic receiving mechanism 34 is composed of a secondary optical prism 341, a solar photovoltaic cell 342, and a tubular water-coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com